High fill compaction quality real-time evaluation method considering underlying surface influence

A technology of compaction quality and evaluation method, applied in design optimization/simulation, geometric CAD, etc., can solve problems such as incomplete evaluation of compaction quality, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

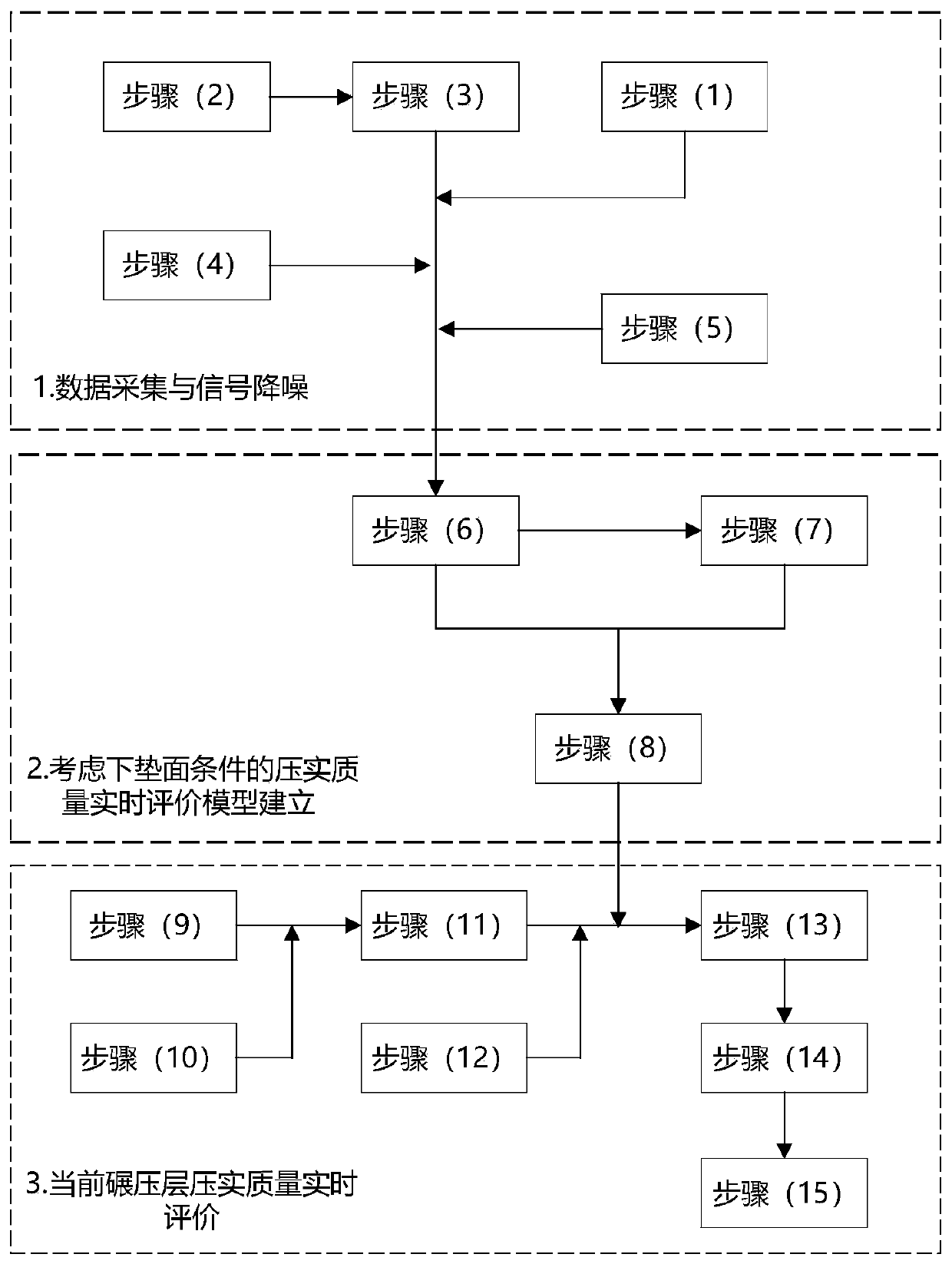

[0045] The present invention is patented in CN103015391A [9] On the basis of the real-time monitoring of compaction quality, the impact of uneven underlying surface is further considered, and the impact of rolling parameters and filler properties is comprehensively considered to obtain a more accurate real-time compaction quality that can adapt to different construction conditions. evaluation method.

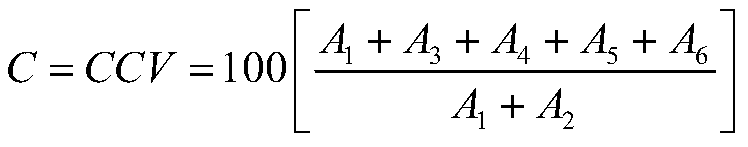

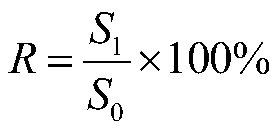

[0046] In order to realize the real-time evaluation of filling compaction quality under the condition of uneven underlying surface, this method is based on the real-time monitoring device of compaction quality (CN105915594A [8] ) and rolling process real-time monitoring device (CN101582198 [5] 、CN101577043 [6] ), a new real-time evaluation model of compaction quality is proposed. For the rolling layer to be evaluated, the impact of the underlying surface on its compaction index can be considered as the impact of the compaction quality of several adjacent underlying layers on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com