Multifunctional wire marking pipe processing device

A processing device and wire number tube technology, which is applied in the manufacture of circuit/collector parts, contact box/base, electrical components, etc., can solve the problems of cumbersome operation steps and low production efficiency, and achieve simplified operation steps, Eliminate damage and waste, and eliminate the effects of the re-stripping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and preferred embodiments, but the protection scope of the present invention is not limited to the following specific embodiments.

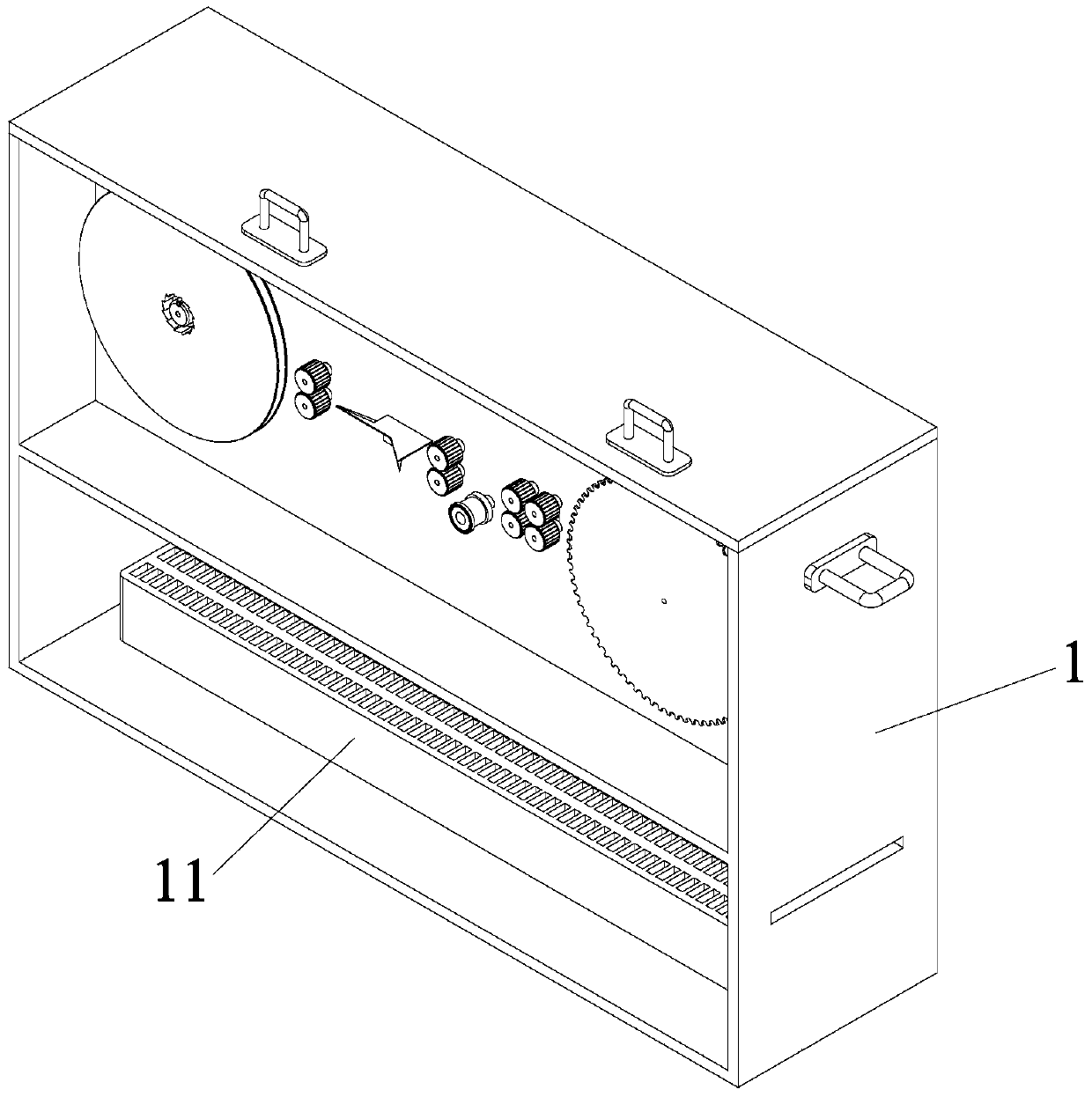

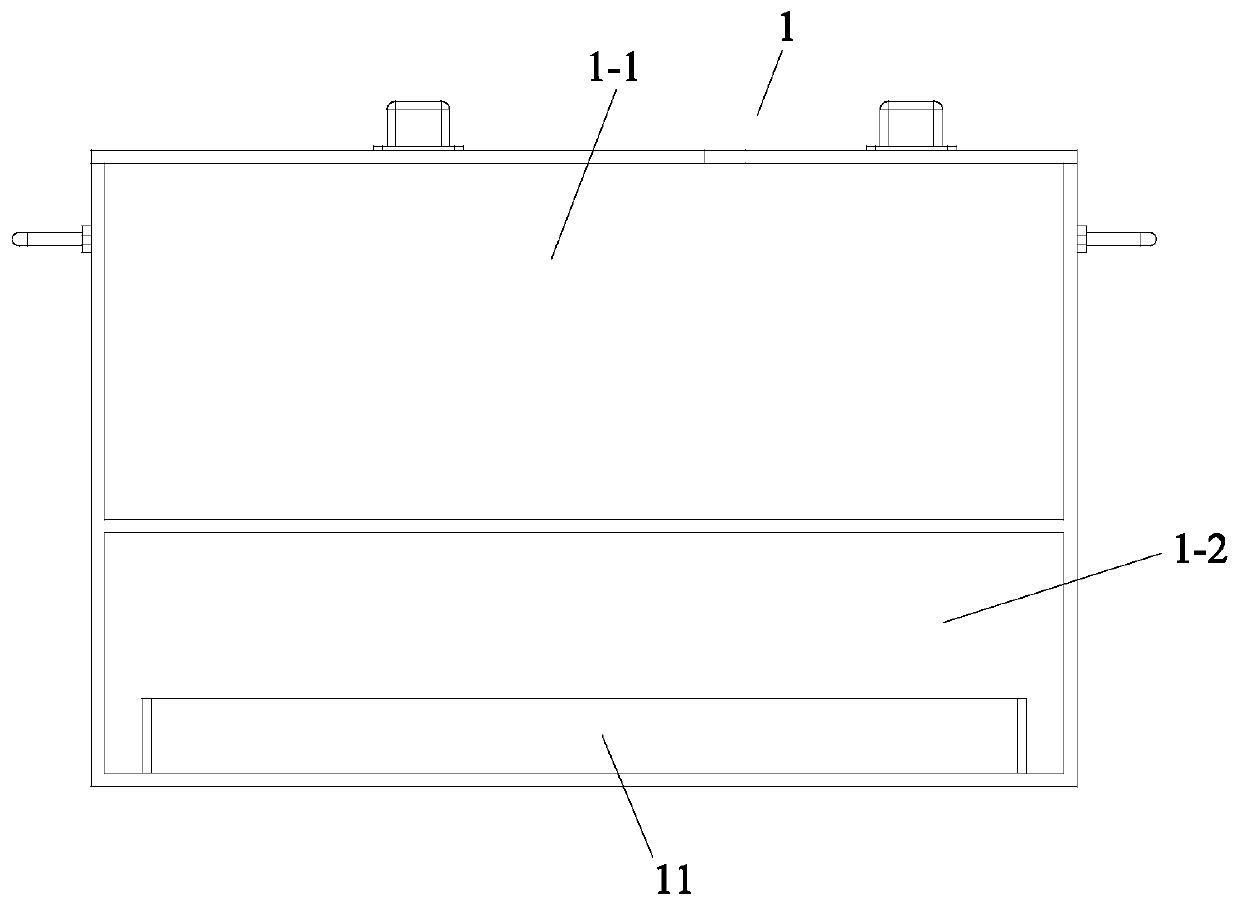

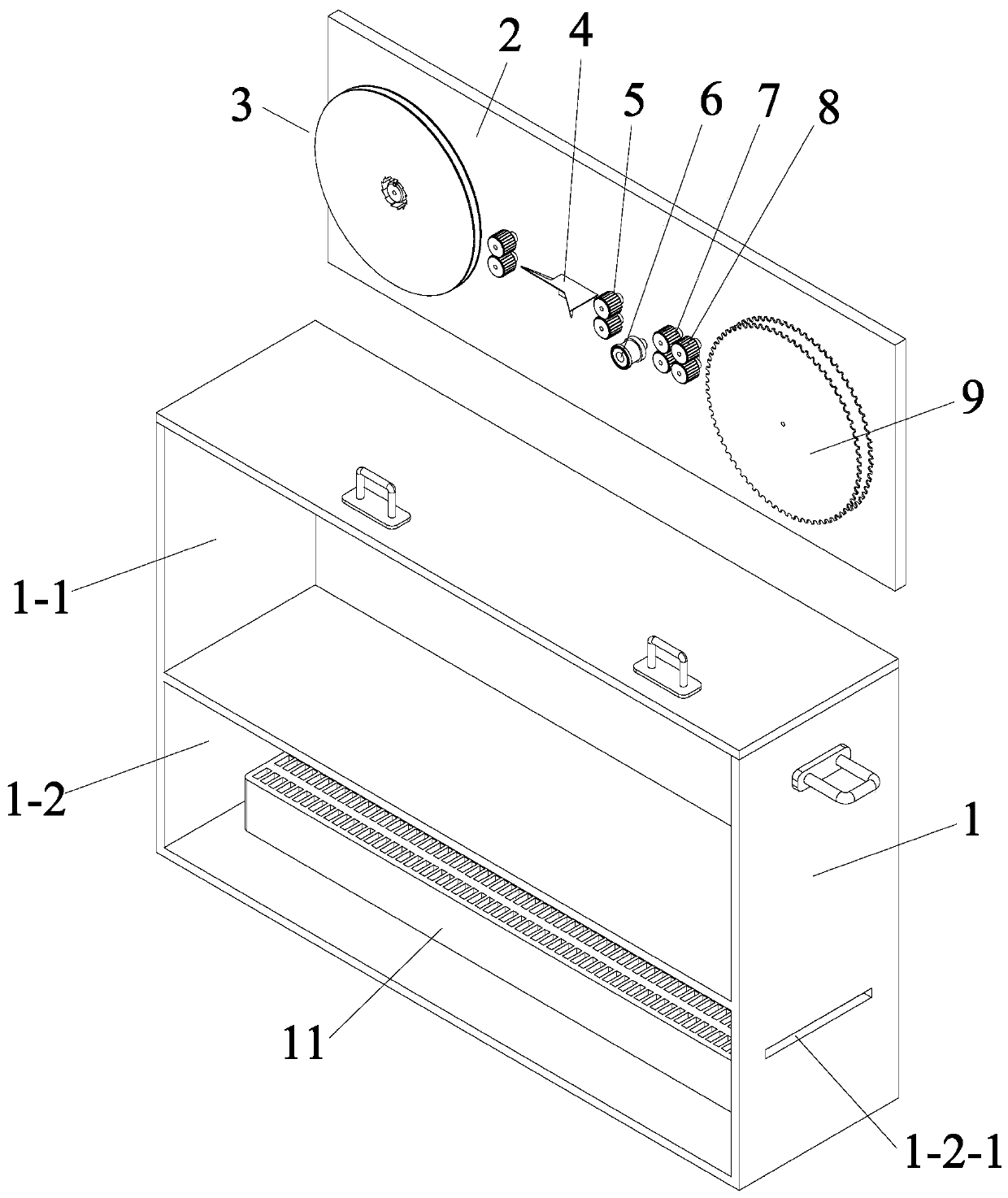

[0032] Such as Figure 1 to Figure 9 As shown, the multifunctional processing device for wire number tubes of the present invention includes a portable box body 1, a pretreatment mechanism mounting seat plate 2, a tubular wire number tube pay-off reel 3, a tubular wire number tube pay-off roller group 4, an opening and an unfolding Mechanism 5, strip wire tube flattening roller group 6, strip wire tube punching roller group 7, strip wire tube straightening roller group 8, strip wire tube reel 9, double-sided adhesive supply mechanism 10 and electric heater 11, tubular wire number tube pay-off reel 3, tubular wire number tube pay-off roller group 4, strip wire number tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com