VCM motor base structure, VCM motor, photographic device and electronic product

A motor and bottom surface technology, applied in the field of photographic equipment, can solve the problems of cracking of the dustproof ring, affecting the performance and appearance of the motor, and narrow width of the dustproof ring, so as to avoid cracking, increase the contact fixing area, and improve the aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

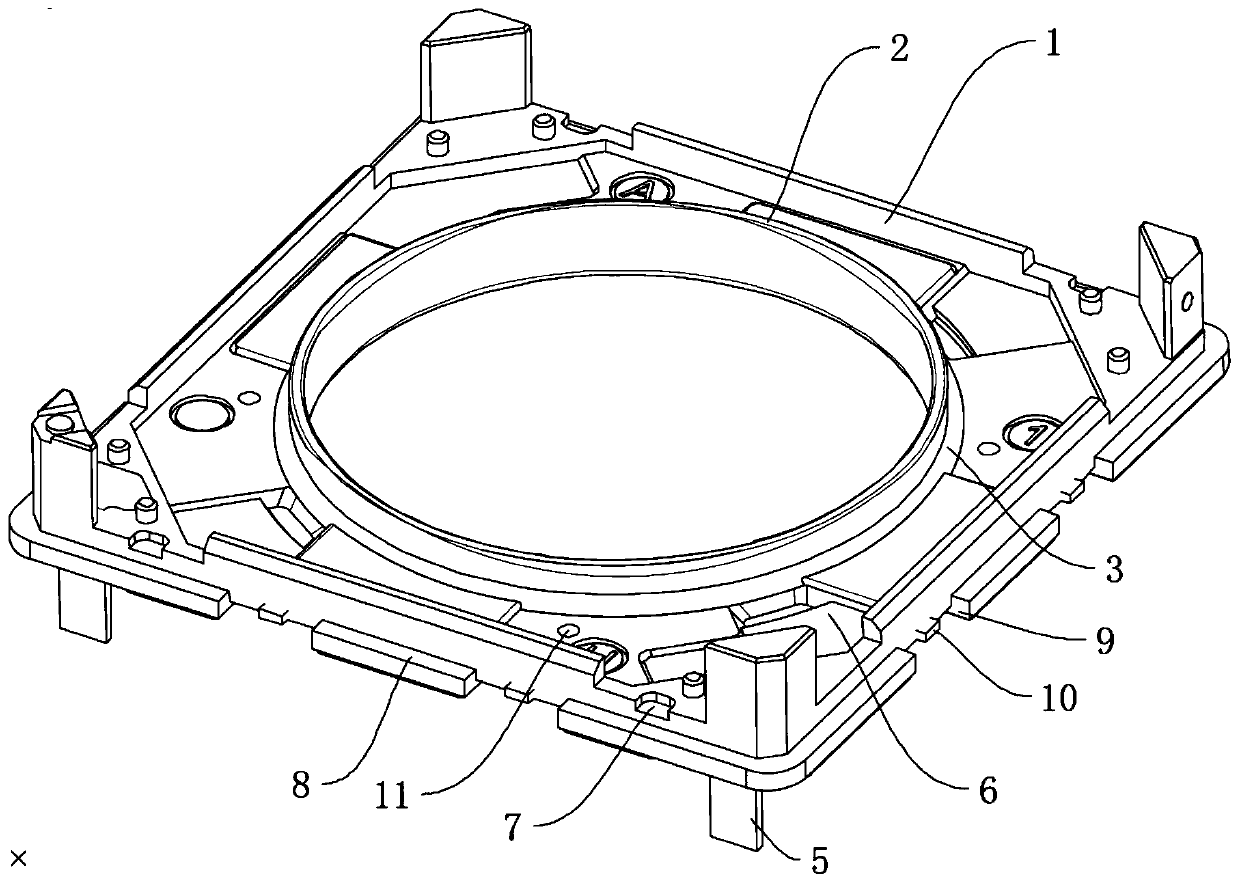

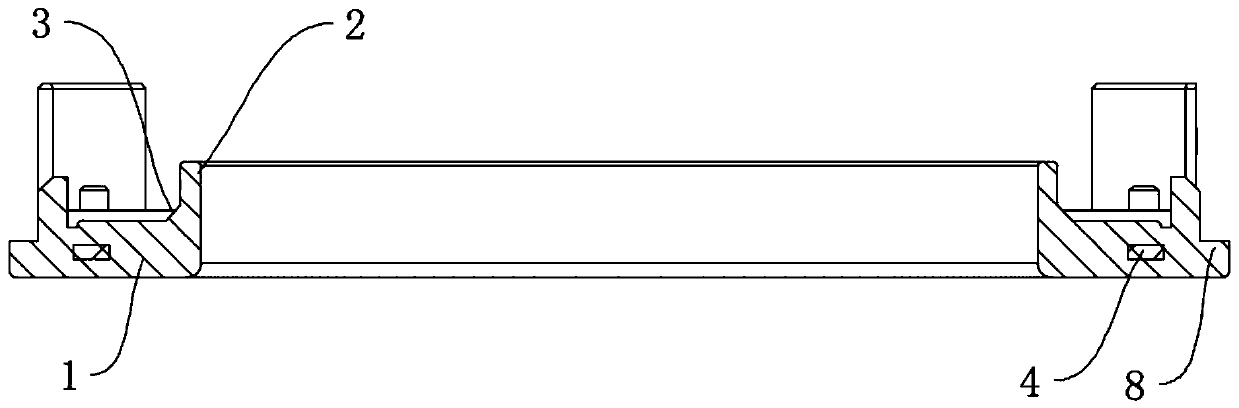

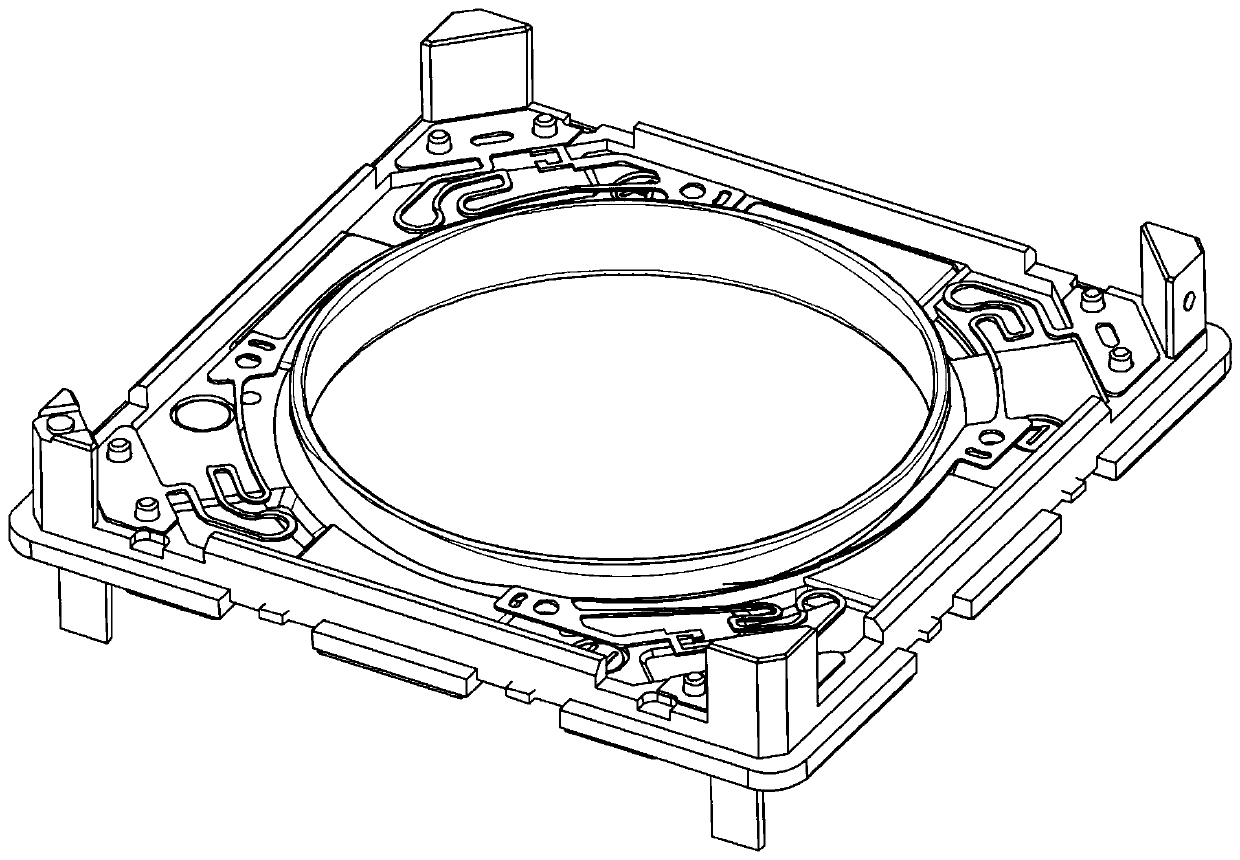

[0029] Example 1 as Figure 1 to Figure 3 As shown, a VCM motor base structure proposed by the present invention includes a base body 1, the base body 1 is provided with a dust-proof ring 2, the dust-proof ring 2 is higher than the bottom surface of the base body 1, and the base body A C corner block 3 is integrally formed at the angle between the bottom surface of 1 and the side wall of the dustproof ring 2, and the C corner block 3 is annularly arranged at the angle between the bottom surface of the base body 1 and the side wall of the dustproof ring 2 position, and the position of the welding line of the base body 1 is located at the position of the C corner block 3, the metal reinforcement rib 4 is injected into the base body 1, the lower end surface of the base body 1 is provided with a connecting terminal 5, and the VCM The lower spring in the motor is electrically connected to the connecting terminal 5 . The connection strength of the dust-proof ring 2 is effectively i...

Embodiment 2

[0033] Embodiment 2, a VCM motor base structure, differs from Embodiment 1 in that: in this embodiment, the C corner block 3 is arranged in several sections between the bottom surface of the base body 1 and the side wall of the dustproof ring 2 corner position, and the welding line position of the base body 1 is located at the position of the C corner block 3 .

Embodiment 3

[0034] Embodiment 3, a kind of VCM motor, such as Figure 4 to Figure 7 As mentioned above, there is a VCM motor base structure described in Embodiment 1 or Embodiment 2, including a lower spring 12 , an upper spring 13 , a carrier 14 , a magnet 15 , and a housing 16 .

[0035] The upper spring 13 includes an outer ring 17 fixedly connected to the bottom surface of the housing 16, an inner ring 18 fixedly connected to the carrier 14, and a cantilever 19 arranged between the outer ring 17 and the inner ring 18. The shell 16 and the magnet 15 clamp and fix the outer ring 17, the cantilever 19 is set to four, and the four cantilever 19 are respectively arranged at the four corners of the base body 1, and one end of the cantilever 19 is connected to the inner ring 18 , the other end is connected to the outer ring 17, and the connecting end of the announcement and the inner ring 18 is located at the middle section of the base body 1, and the connecting end of the cantilever 19 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com