Battery element having a thermal conduction element

A technology of battery components and battery cells, applied in battery pack components, batteries, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

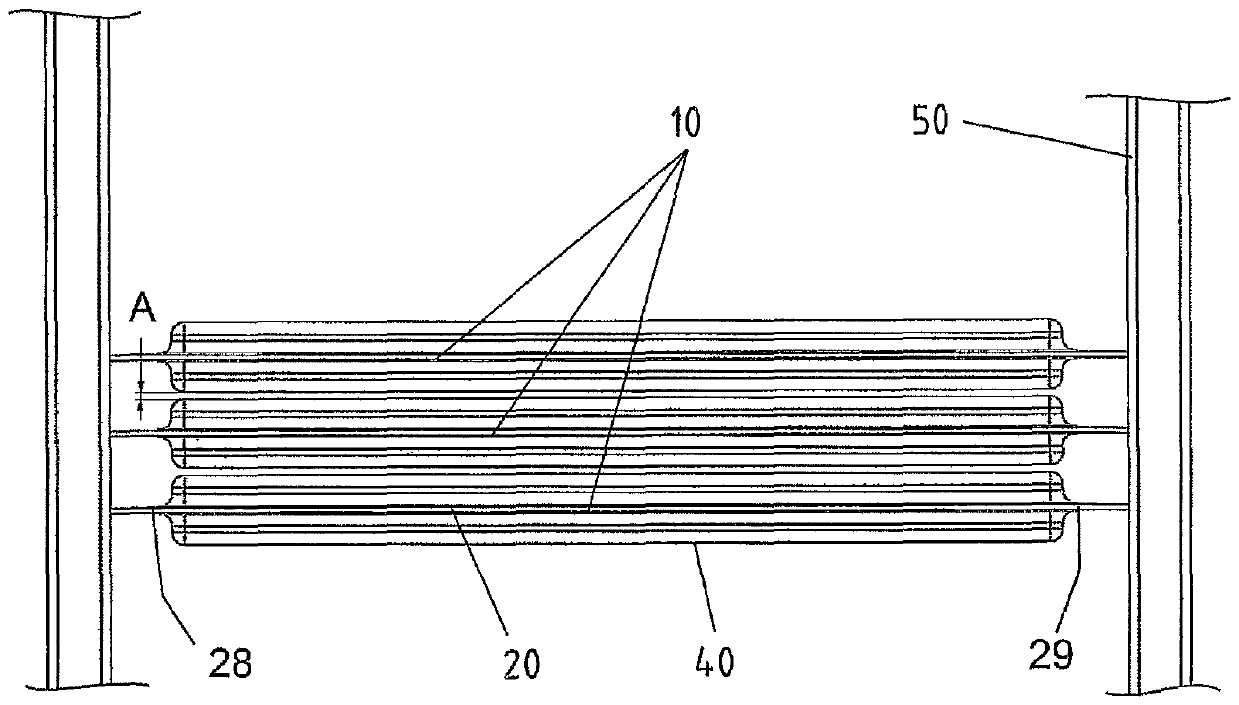

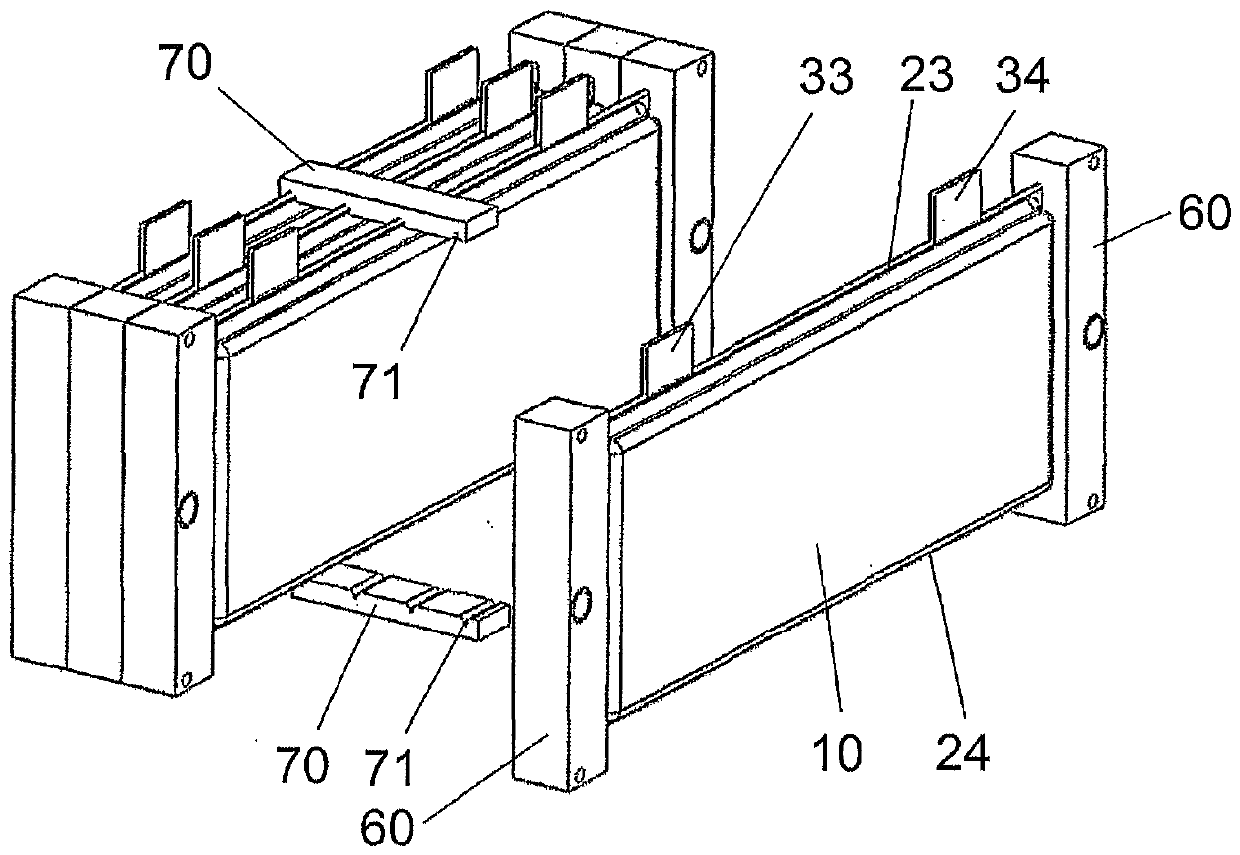

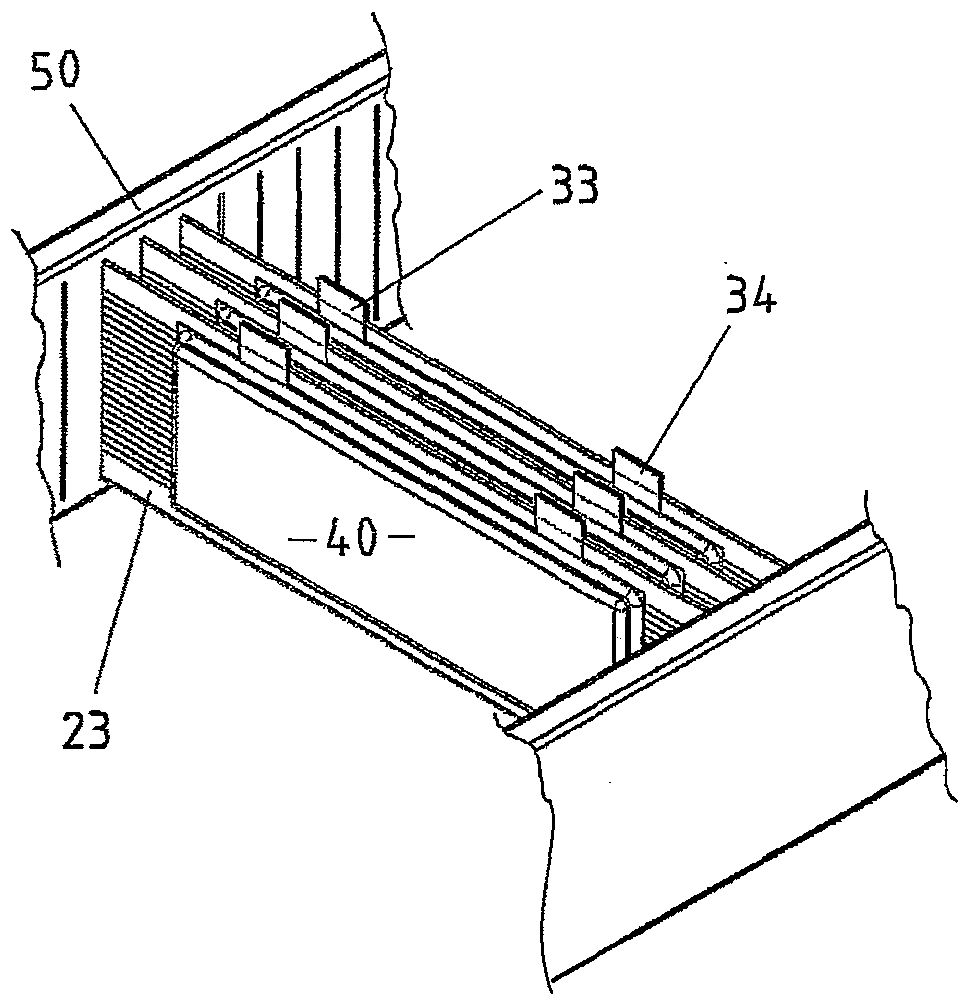

[0039] figure 1 The new battery element 10 shown comprises two electrode stacks 30 , 30 ′, which are arranged on both sides of a heat-conducting element provided for temperature control. The heat conducting element is a flat multi-chamber hollow profile 20 . The electrode stacks 30 , 30 ′ are only shown abstractly. They comprise electrodes 31 which are arranged to be folded into active layers together with the electrolyte and which are present separated from one another by a separator 32 . The electrode stack 30 , 30 ′ is surrounded on the outside by an outer sheath 40 or 40 ′. In contrast to known pouch-shaped cells in which the electrode stacks are likewise surrounded by an outer casing, the new battery element 10 includes two electrode stacks and additionally includes a centrally arranged multi-chamber hollow profile 20 as an integral component. Such a multi-chamber hollow profile has a plurality of chambers 21 arranged next to one another and running in parallel. On th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com