Method and apparatus for making semi-solid metal slurry

a technology manufacturing method, which is applied in the field of method and apparatus for manufacturing semi-solid metal slurry, can solve the problems of reducing the productivity of semi-solid metal slurry, difficult to achieve entirely uniform and fine structure, and serious non-uniform structure, etc., and achieves the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

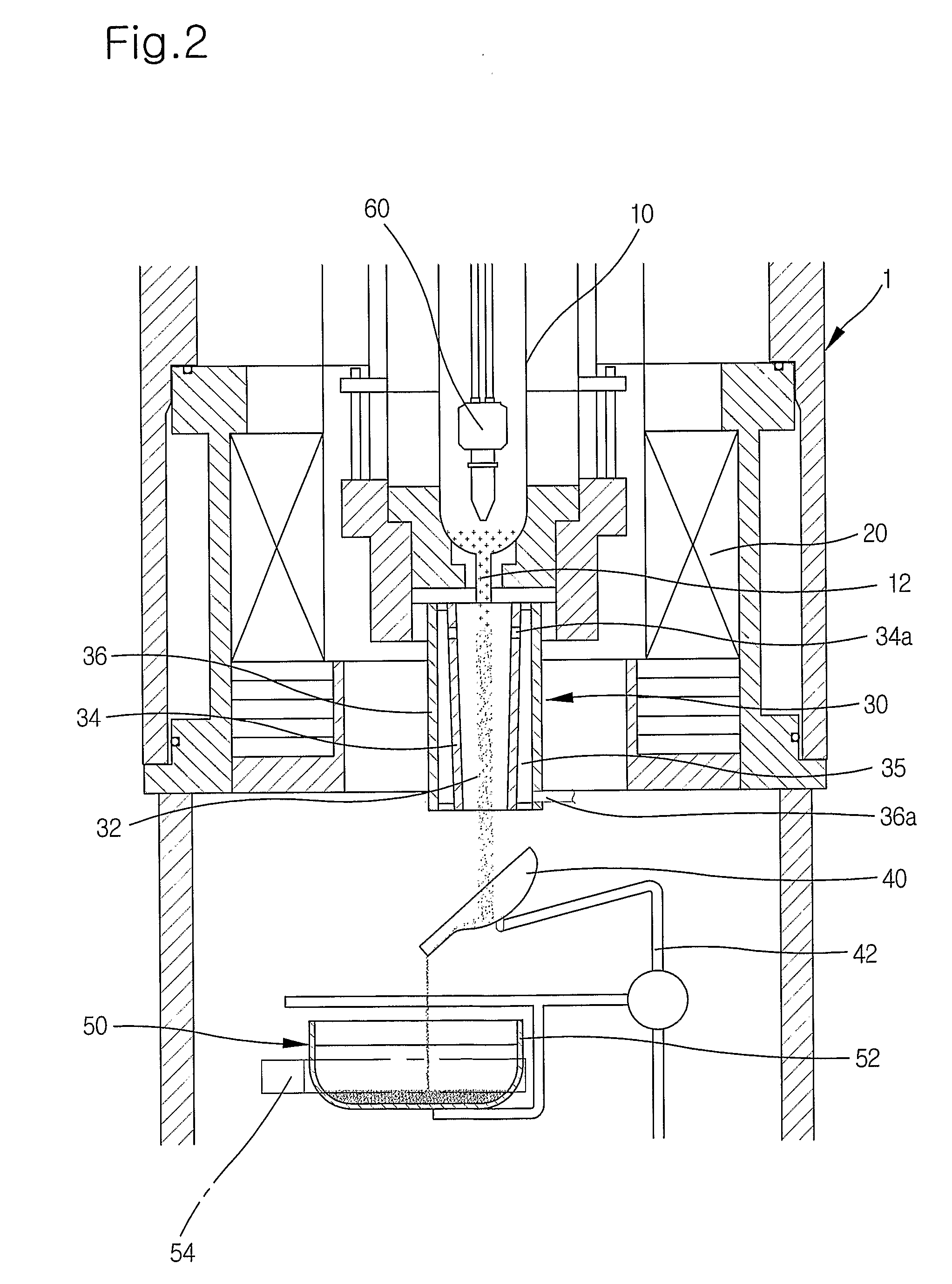

[0029] Preferred embodiments will now be described in detail with reference to the accompanying drawings.

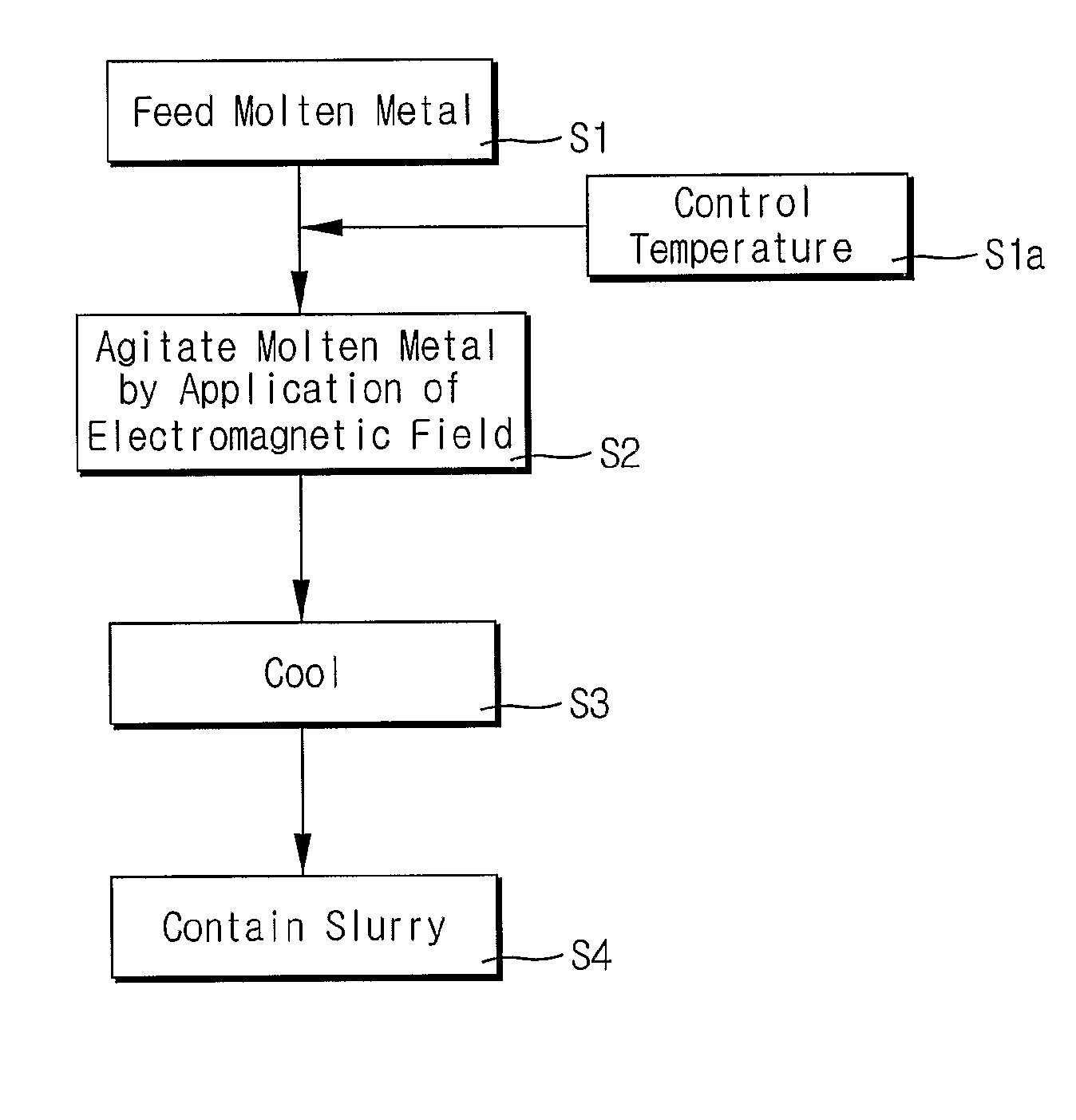

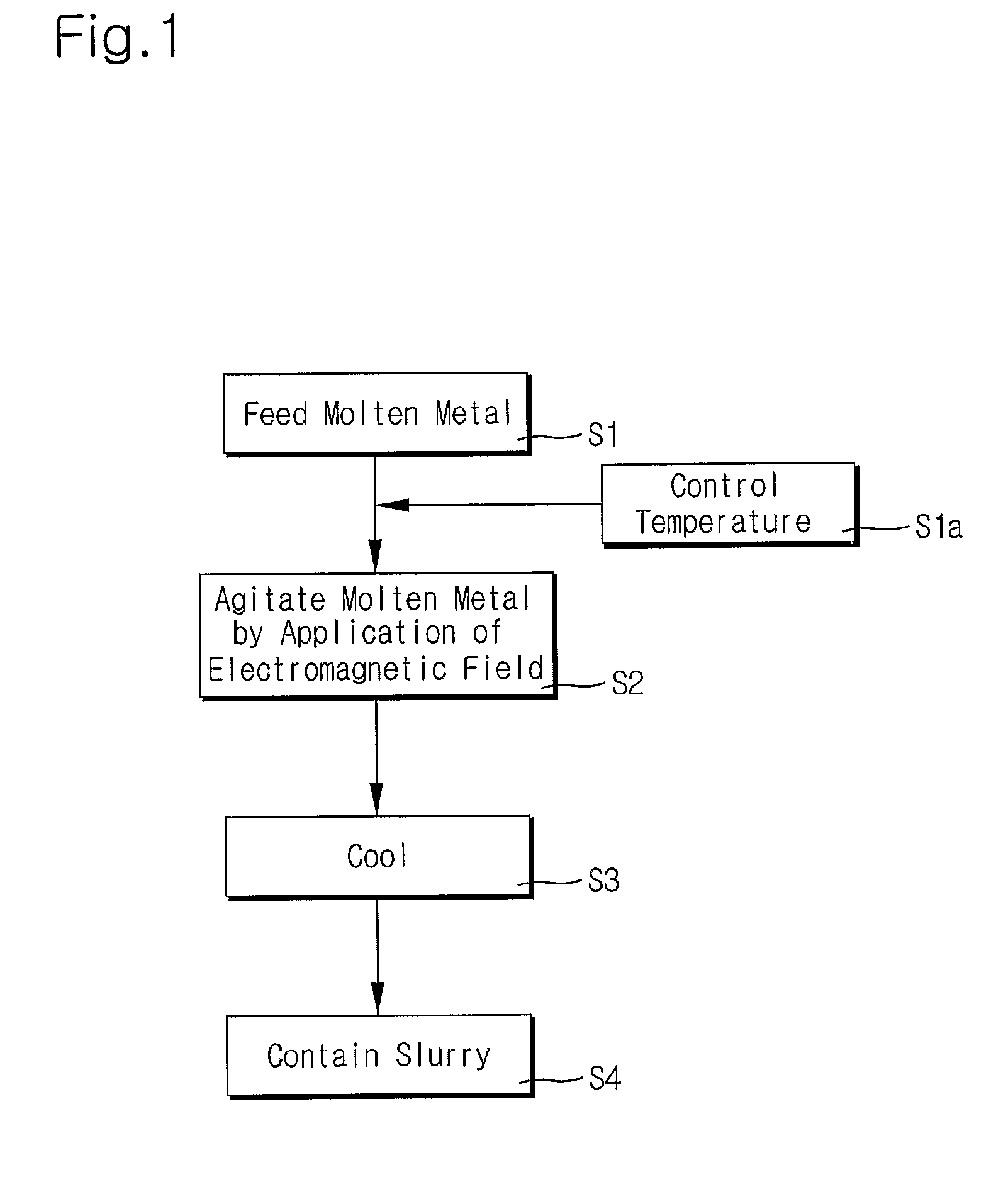

[0030]FIG. 1 is a schematic block diagram illustrating a method for manufacturing a semi-solid metal slurry according to the invention.

[0031] The method of the invention can manufacture a semi-solid metal slurry having a uniform and non-directional spherical structure, which provides excellent results in tests for workability for forming a complicated shape, dimensional precision, formability, heat treatment, pressure resistance associated to a bubble defect, while providing excellent productivity, and which has excellent wear resistance, elongation, hardness, and tensile strength.

[0032] The method of the invention comprises step S1 of feeding molten metal into a furnace through a pouring port of a well-known ladle; step S2 of agitating the molten metal in the furnace by application of an electromagnetic field through an electromagnetic agitator, thereby removing a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com