Novel digital folding planar mask machine

A flat and foldable technology, applied in typewriters, clothing, printing, etc., can solve the problems of low efficiency, inability to realize personalized mask customization, single pattern printing, etc., achieve high integration, meet the needs of pattern customization, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention. It should be noted that relative terms such as "first", "second" and so on may be used to describe various components, but these terms do not limit the components. These terms are only used to distinguish one component from another. For example, without departing from the scope of the present invention, a first component may be called a second component, and a second component may similarly be called a first component. The term "and / or" refers to any one or more combination of related items and described items.

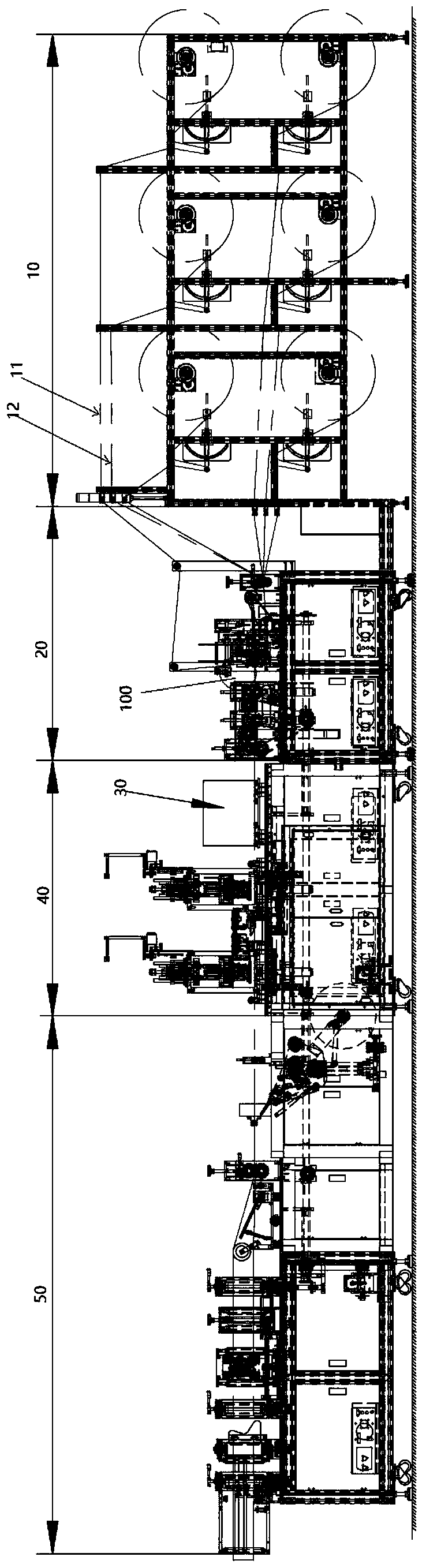

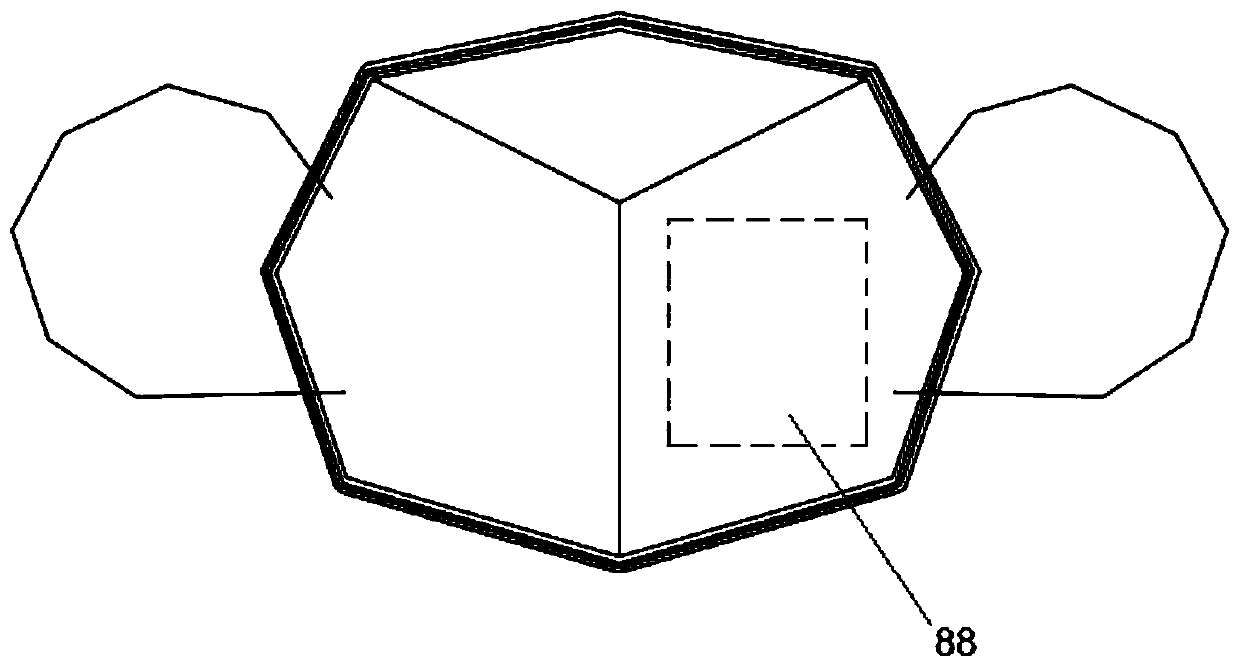

[0020] like figure 1 as shown, figure 1 It is a structural schematic diagram of the new digital folding plane mask machine of the present invention; it includes a cloth feeding mechanism 10, a welding unit 20, a digital printing mechanism 30, an ear wire unit 40 and a die-cutting unit 50, and the welding uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com