Material receiving and weight measuring mechanism, seasoning machine and control method thereof

A control method and seasoning machine technology, which can be applied to home appliances, applications, kitchen utensils, etc., can solve problems such as inaccurate weight detection, achieve accurate distribution, improve the accuracy of weight measurement, and improve the use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

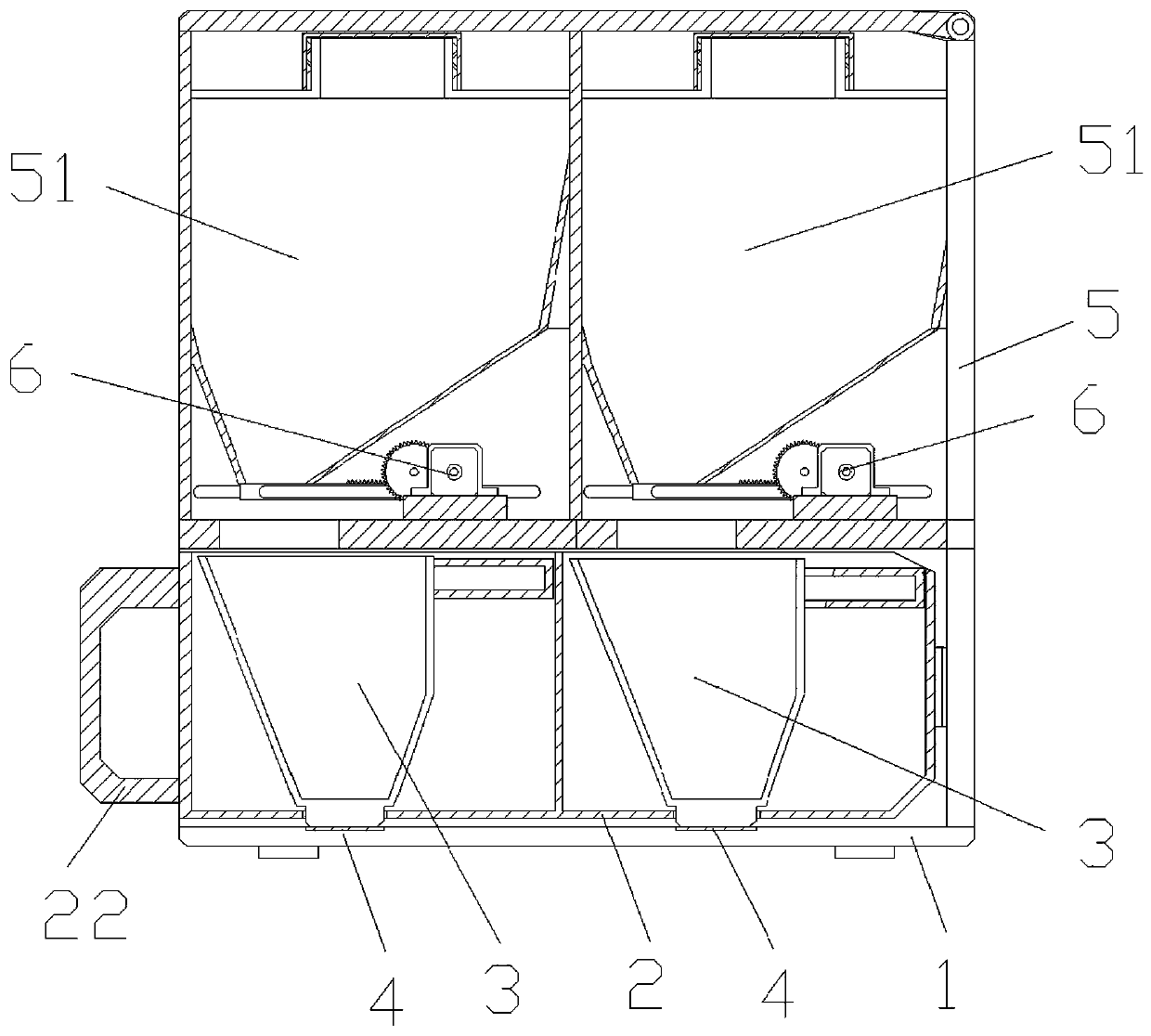

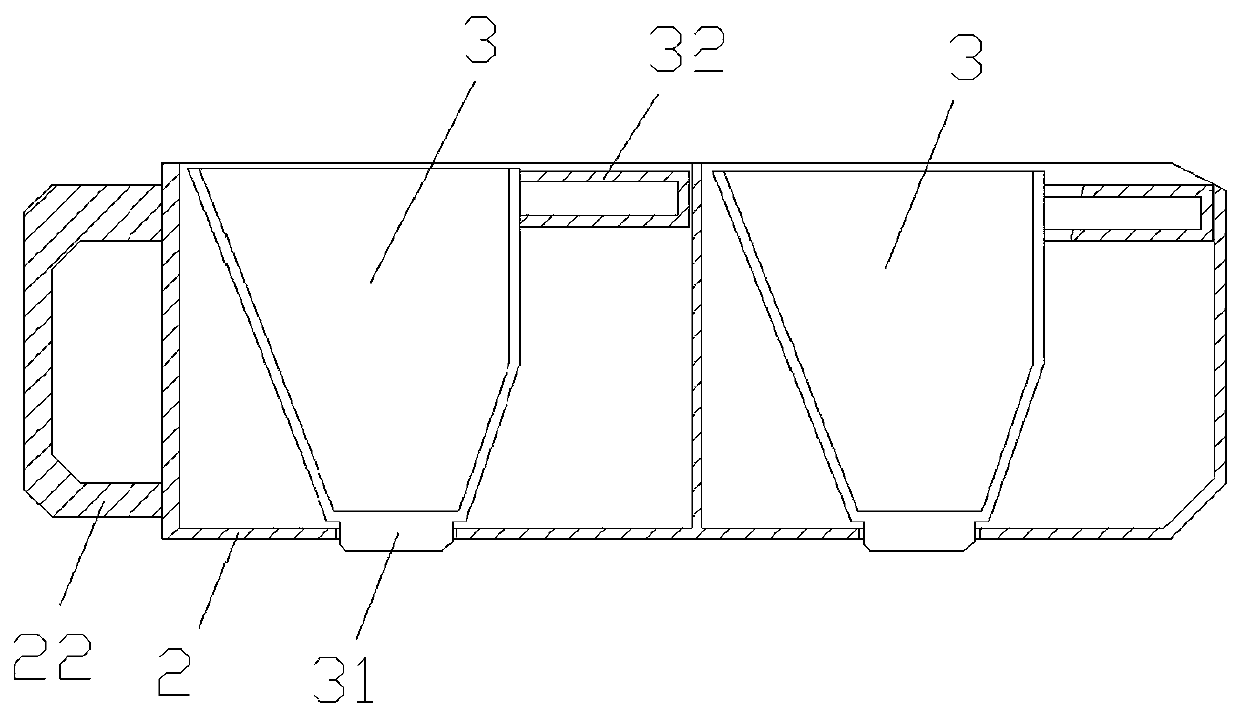

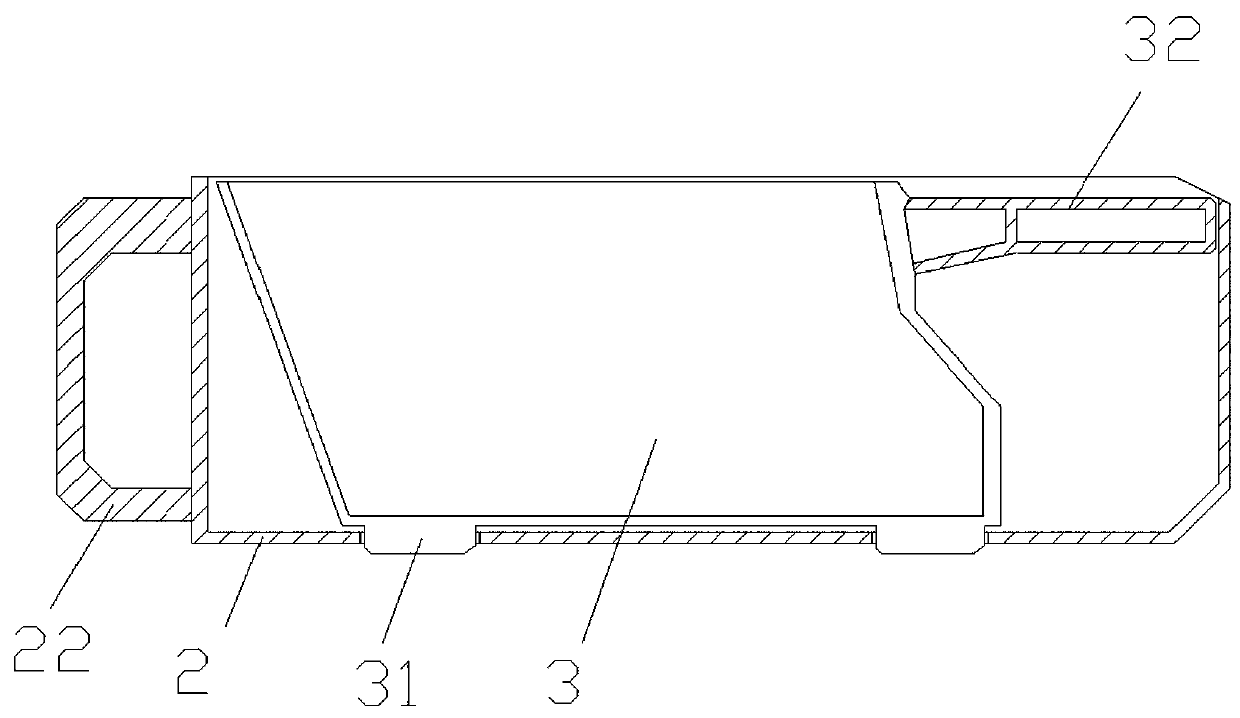

[0032] Such as figure 1 , 2 As shown, the present invention proposes a material receiving and weighing mechanism, including: base 1, main material box 2 and auxiliary material box 3, etc., at least one main material box 2 is placed on the base 1, the main material box 2 and auxiliary material box 3 The tops are all open, and each main magazine 2 can accommodate at least one auxiliary magazine 3 , and the base 1 is provided with sensors 4 corresponding to the auxiliary magazines 3 one by one. The bottom surface of the auxiliary material box 3 is provided with a protruding foot 31, and the sensor 4 corresponding to the auxiliary material box 31 is located directly below the protruding foot 31. The foot 31 is supported on the corresponding sensor 4 through the through hole 21, and the weight of the auxiliary magazine 3 is detected by the sensor 4. The sensor 4 can be a pressure sensor, and the sensor 4 detects the pressure value of the auxiliary magazine 3.

[0033] When the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com