Spraying robot and spraying method

A technology for spraying robots and spraying surfaces, which is applied to aircraft parts, spraying devices, launching devices, etc., can solve the problems of small application range, high energy consumption, and low precision of spraying drones, so as to improve spraying accuracy and increase spraying distance. , the effect of low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

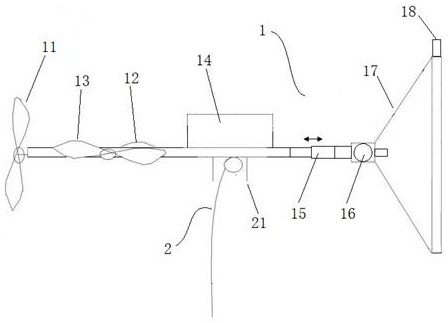

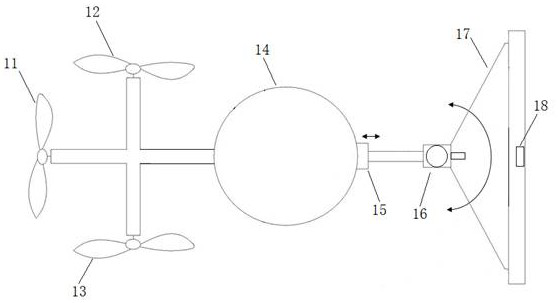

[0072] This embodiment provides a spraying robot, such as figure 1 , figure 2 and Figure 6 As shown, it includes: UAV 1, tethered rope 2 and ground trolley 3; for example, UAV 1 is a quadrotor UAV or others.

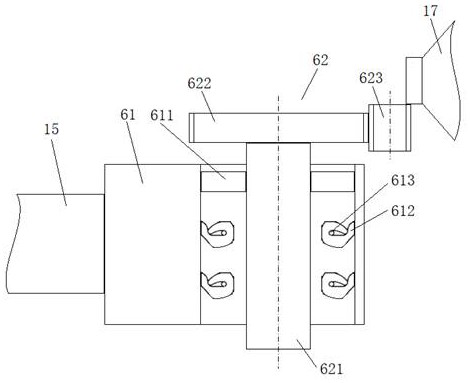

[0073] UAV 1 comprises spraying reaction force regulating device, four-rotor mounting base 14, telescopic rod device 15, steering gear 16, spraying device 17 and distance and angle detection device 18; Connection; the telescopic rod device 15 is installed directly below the center of gravity of the four-rotor mount 14, including a telescopically adjustable rod for driving the spraying device 17 to move forward and backward with the telescopic adjustment of the rod; the steering device 16 includes Fixed seat 61 and rotating body 62, fixed seat 61 is connected with one end of telescopic rod device 15, and rotating body 62 is connected with spraying device 17, is used to drive spraying device 17 to rotate left and right with the rotation adjustment of rotating body 62; ...

Embodiment 2

[0084] Spraying preparation: After the control parameters are input into the controller of the ground trolley, for example, the GPS / Beidou positioning module is used to control the ground trolley to drive to the predetermined position. At the same time as the UAV takes off, the mooring hoisting device on the ground trolley is controlled by the tension controller The hoisting reel releases the mooring rope with the take-off speed of the UAV; the UAV flies to the preset working height and feeds back to the ground trolley, and the ground trolley controls the spray liquid in the liquid storage device and sends it to the unmanned aerial vehicle through the tethering rope. machine spraying device.

[0085] After finishing the spraying preparatory steps, this embodiment provides a spraying method that can be applied to the controller 32 to complete the spraying. Such as Figure 7 Shown, this spraying method comprises the following steps:

[0086] S1. Obtain the angle between the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com