Two-time hardening shower coating production line for mask of automotive headlamp

A technology for automotive headlights and production lines, which is used in devices for coating liquids on surfaces, coatings, and pretreatment surfaces. , Unable to achieve the problem of coating film thickness and appearance, to achieve the effect of increasing the flexibility of the production line, improving the thickness of the coating, and increasing the flexibility of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

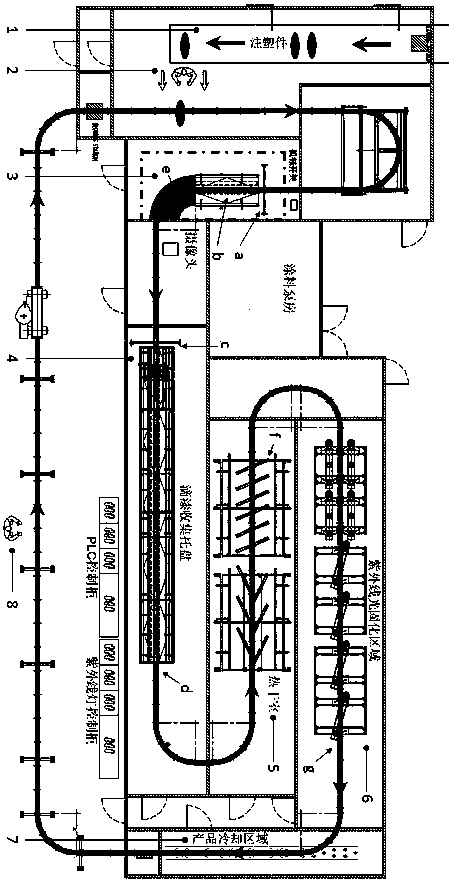

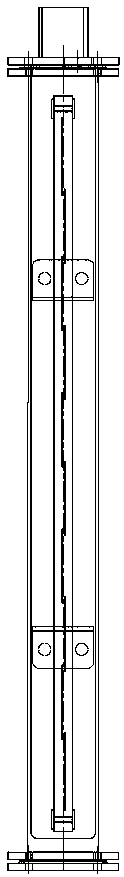

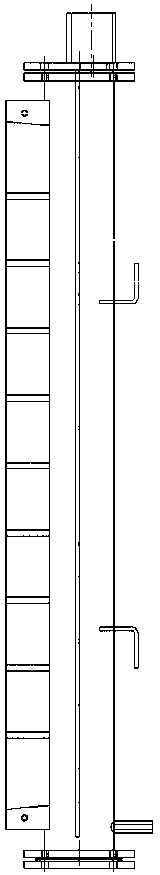

[0036] Such as figure 1 , the present embodiment provides a two-time hardening coating production line for automobile headlamp masks, including a conveyor belt 1 for injection molded parts of the mask, a feeding room 2 from the operator's upper part to the chain fixture, the first coating area 3, and the first coating area 3. Secondary coating area 4, heat drying room 5, ultraviolet light curing area 6, product cooling area 7, product unloading area 8, and high-grade industrial fireproof and explosion-proof clean room covering all the above areas. The lowest grade is ISO7, and all other areas are higher ISO6 grades. The first curtain coating single zone 3 and the second curtain coating zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com