PE tube scraper device and method for scraping material on outer wall of PE tube

A scraper device, the technology of the outer wall of the pipe, which is applied in the field of PE pipes, can solve the problems of easily damaged PE pipes, inconvenient operation, and the pipes cannot be better applied, and achieves the effect of preventing position changes and good scraping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

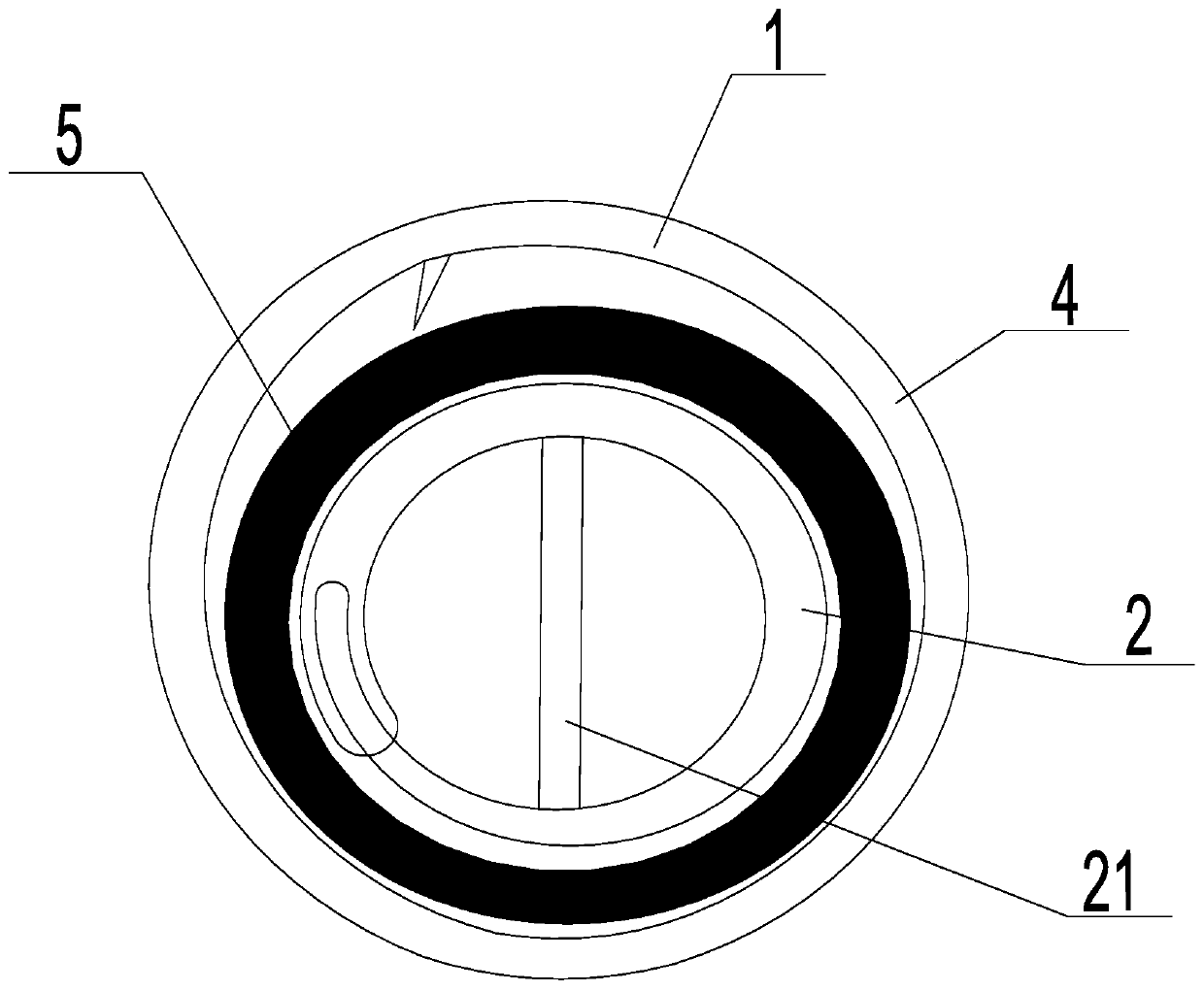

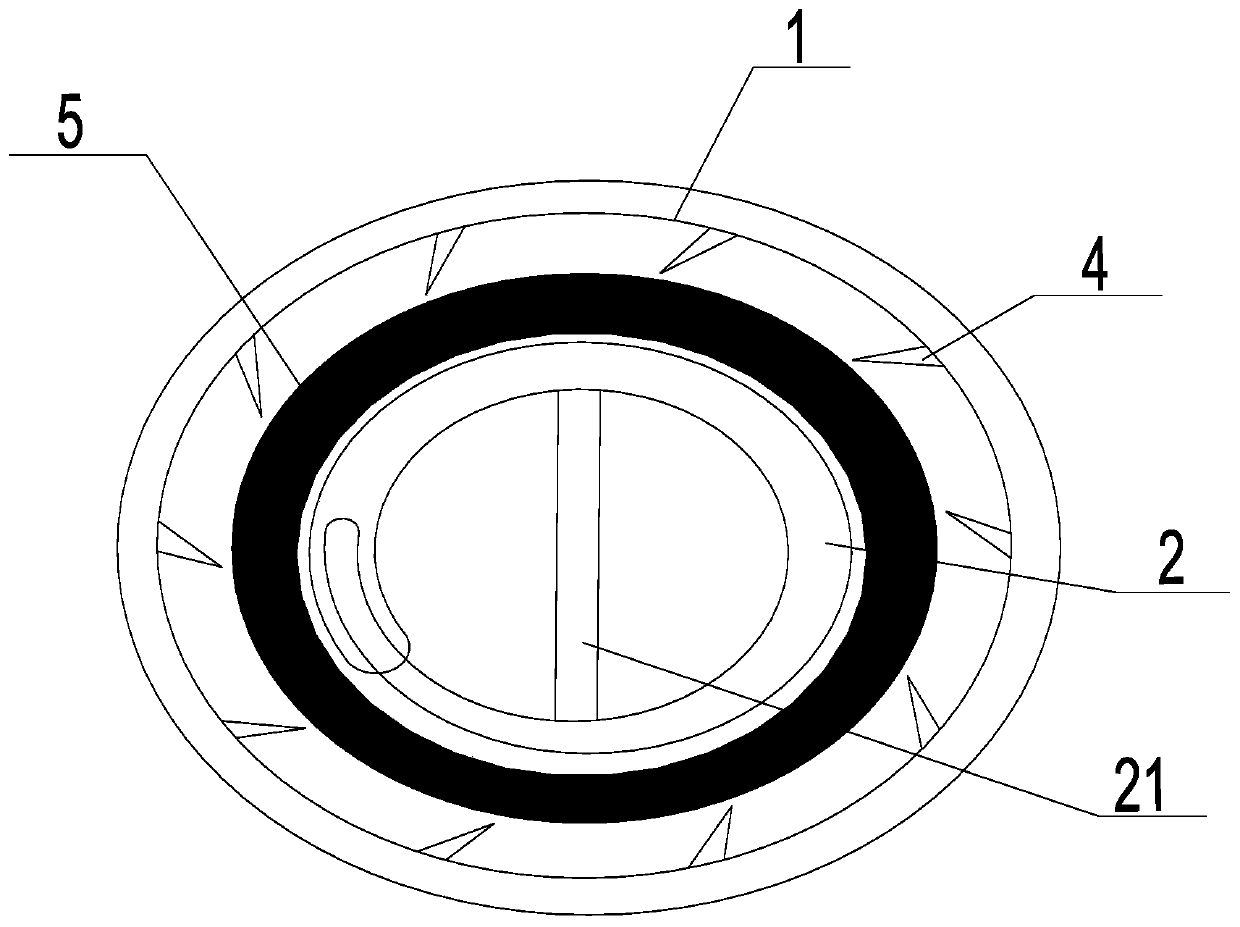

[0061] The PE pipe scraper device of the present invention, such as figure 1 As shown, it includes a first tubular structure 1 and a second tubular structure 2 that both have elasticity, the inner wall of the first tubular structure 1 is sleeved on the outer wall of the PE pipe 5, and the outer wall of the second tubular structure 2 is supported with the inner wall of the PE pipe 5. touch;

[0062] A scraper 4 is arranged on the pipe wall of the first tubular structure 1, and the blade of the scraper 4 is in contact with the outer wall of the PE pipe. Under the action of external force, the first tubular structure 1 drives the scraper 4 on the outer wall of the PE pipe 5 along the PE pipe. 5. Circumferential movement, scraper 4 scrapes the material on the outer wall of the PE pipe during the circumferential movement;

[0063] The shape and size of the second tubular structure 2 matches the shape and size of the inner wall of the PE pipe 5. The pipe wall of the second tubular ...

Embodiment 2

[0067] On the basis of Example 1, the second tubular structure is fixed on the inner wall of the PE pipe 5. When placed, the cross-sectional area of the second tubular structure is reduced by external force. The insertion end of the side is inserted into the opening, and as the size of the second tubular structure is further reduced, the insertion end is further moved into the cavity inside the second tubular structure, and after it is reduced to be smaller than the inner diameter of the PE pipe, the second tubular structure is Put it into the PE tube, so that the side of the second tubular structure is in contact with the inner wall of the PE tube. After being put in, the second tubular structure will automatically adapt to the size of the inner diameter of the PE tube until the inner wall of the PE tube acts on the second tubular structure. The size of the second tubular structure is fixed, and the second tubular structure is further supported. At this time, the second tubu...

Embodiment 3

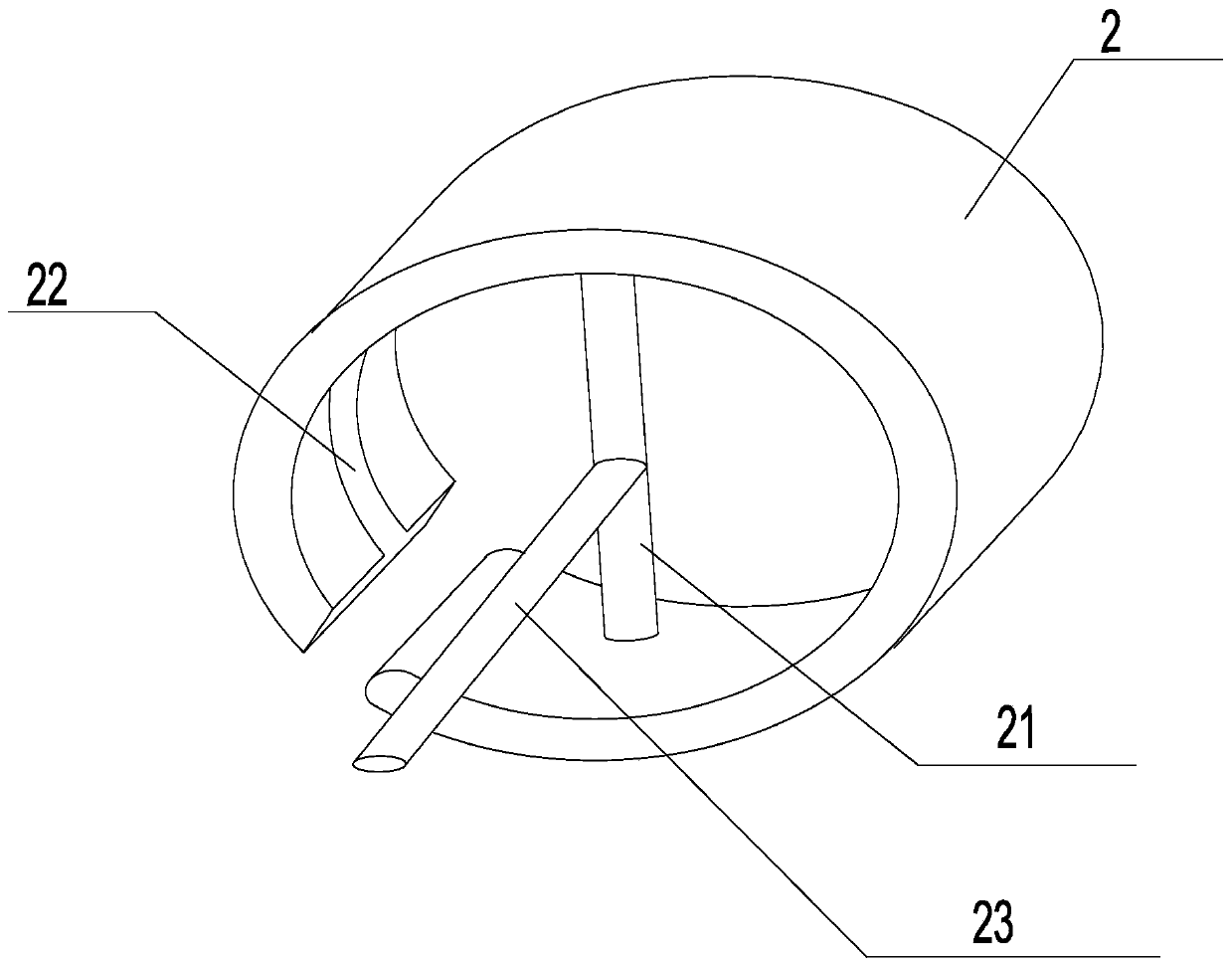

[0071] On the basis of Example 2, the structure of the second tubular structure is as follows image 3 and 4 shown, image 3 It is the structure of the second tubular structure when there is no external force. When the insertion end of the second tubular structure is inserted into the open end, its structure is as follows: Figure 4 shown. like Figure 9 and 10 As shown, a telescopic rod 21 is connected to the inner wall of the second tubular structure 2. The telescopic rod 21 is located on the plane where the cross section of the second tubular structure 2 is located. The length of the telescopic rod 21 is adjusted according to the shape and size of the second tubular structure 2. The rod 21 includes an accommodating cavity 201 with one end open, and an adjusting rod 202. The adjusting rod 202 is sheathed in the accommodating cavity 201, one end of the adjusting rod 202 is connected to the inner bottom of the accommodating cavity 201 through a spring 203, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com