Cooling device for container Q235C steel smelting

A technology for cooling device and container steel, applied in the field of steel smelting and processing, can solve the problem of low circulating utilization rate of cooling water, and achieve the effect of being convenient for recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

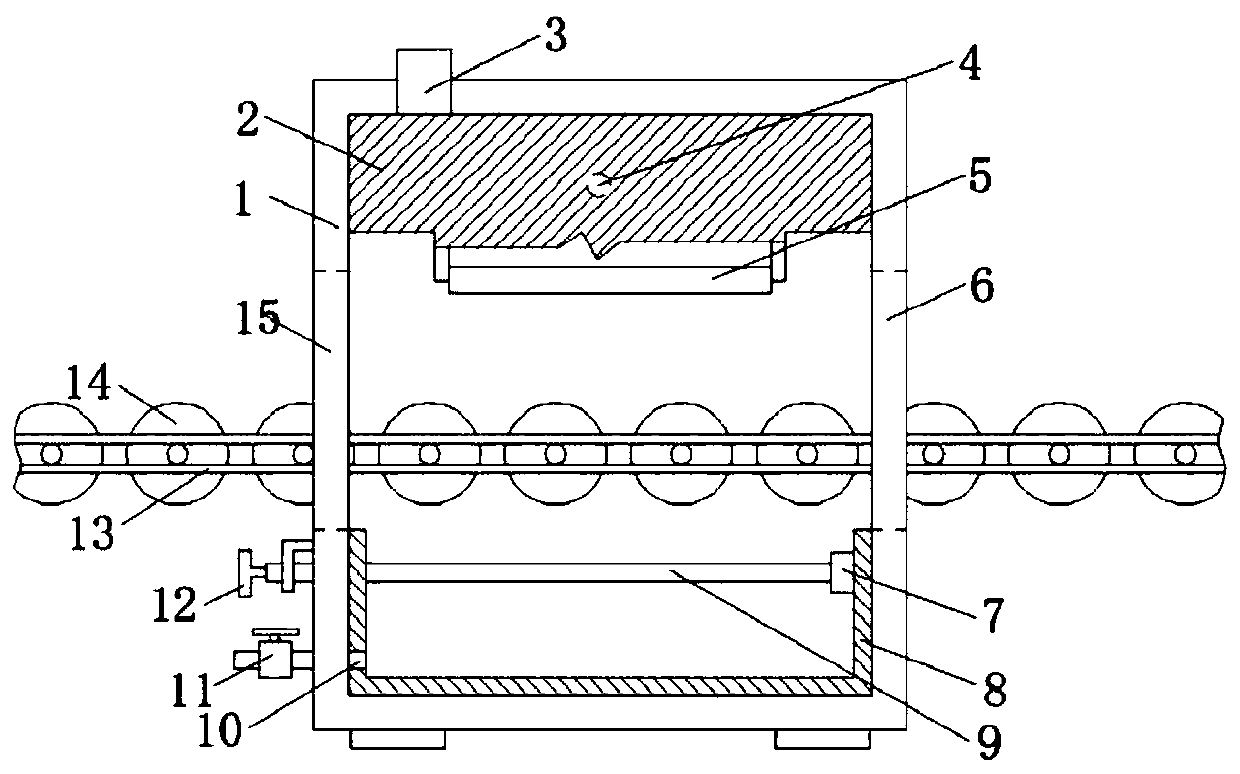

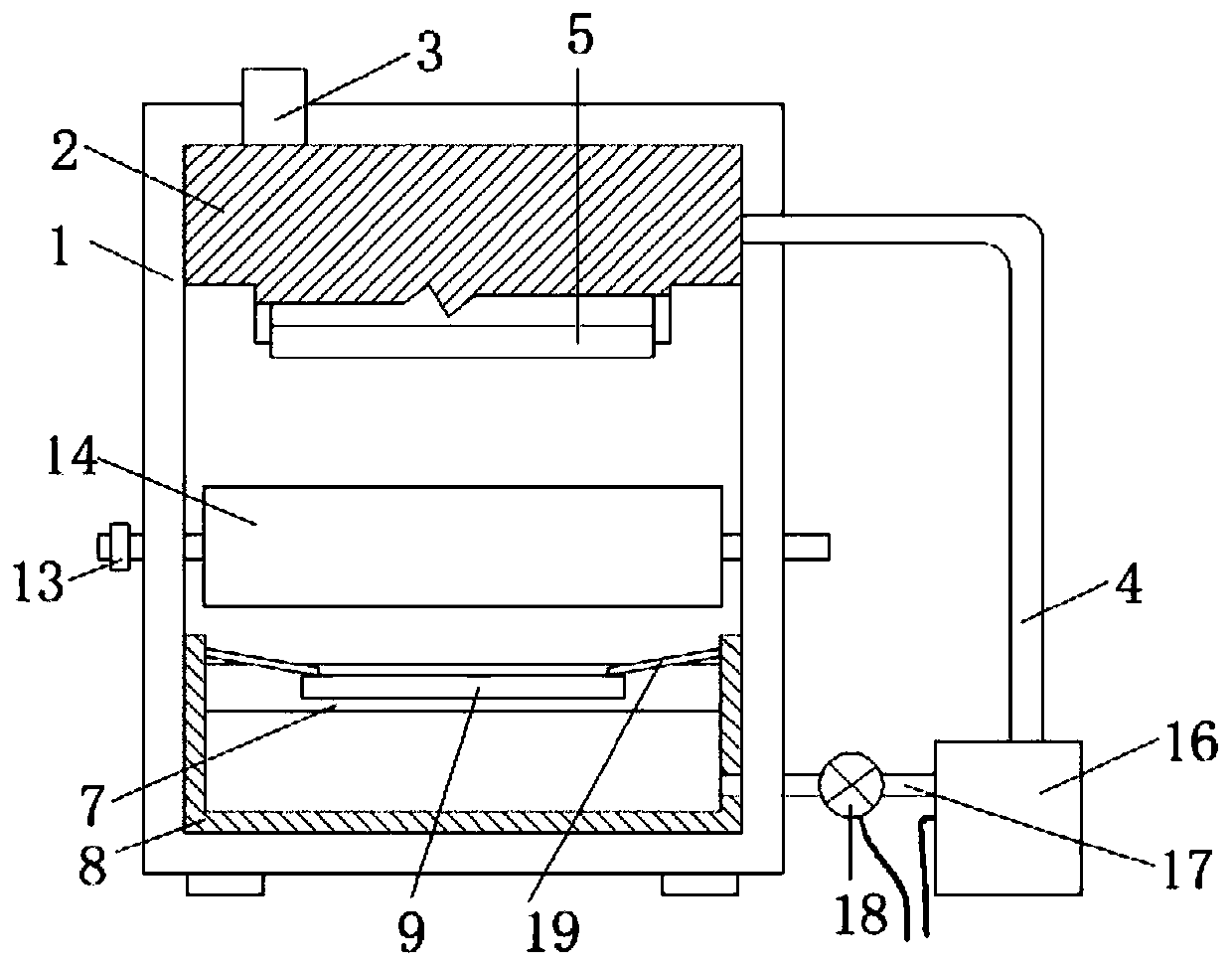

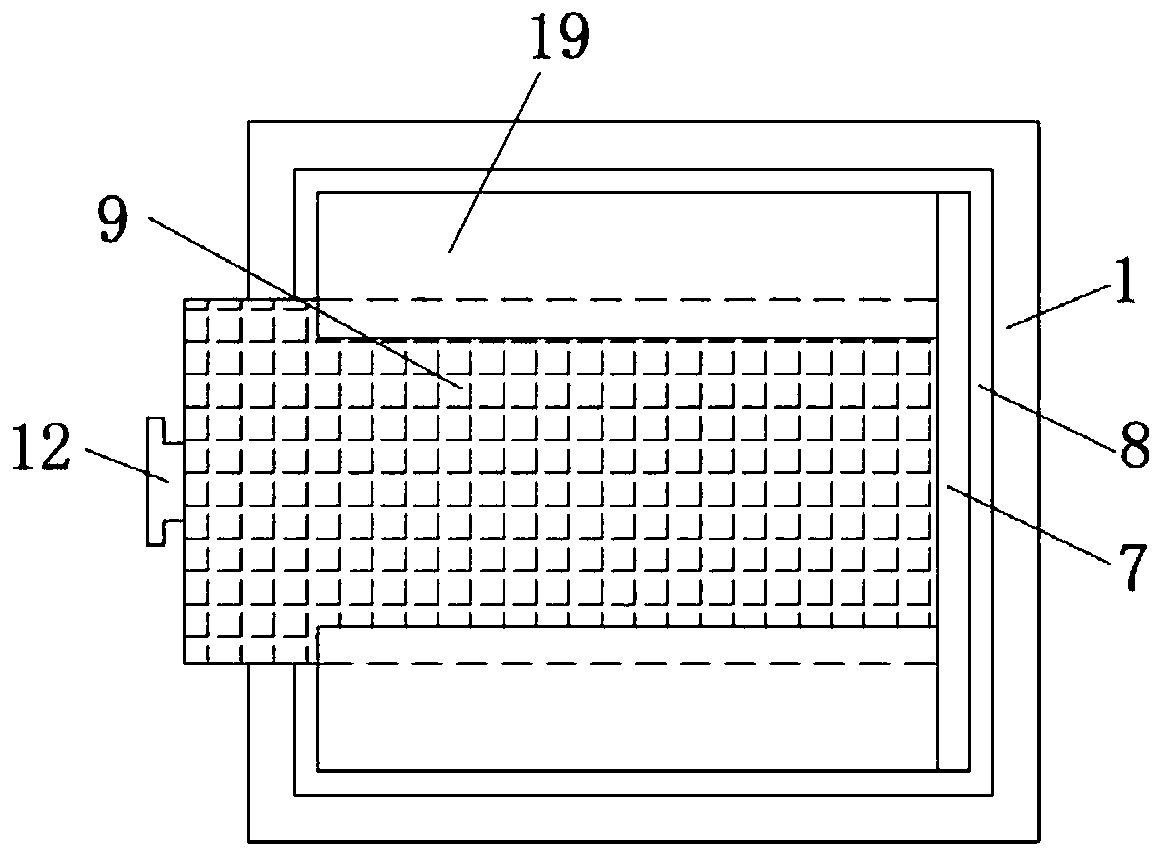

[0022] Example: refer to Figure 1-3 , a cooling device for container steel smelting, comprising a cooling chamber 1, a water storage tank 2, a water outlet network 5, a recovery shell 8 and a water refrigeration circulator 16, one end of the cooling chamber 1 is provided with a feed port 15, and the cooling chamber The other end of 1 is provided with a discharge port 6, and a material guide roller 14 connected by a belt 13 is arranged in the cooling chamber 1. The inner top bolt of the cooling chamber 1 is fixed with a water storage tank 2, and the upper part of the water storage tank 2 is provided with a water injection hole, and the bolt is fixed with the water injection pipe 3, and the bottom of the water storage tank 2 is provided with a water outlet net 5;

[0023] The bottom of the water storage tank 2 is provided with a rectangular hole, and a water outlet net 5 is fixed by bolts. The outlet net 5 is provided with evenly distributed mesh holes, and the aperture of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com