Monocrystalline silicon passivation contact structure and preparation method thereof

A contact structure and monocrystalline silicon technology, which is applied in the fields of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc., can solve the problems of poor passivation effect of crystalline silicon, and achieve fast deposition speed and low cost , enhance the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

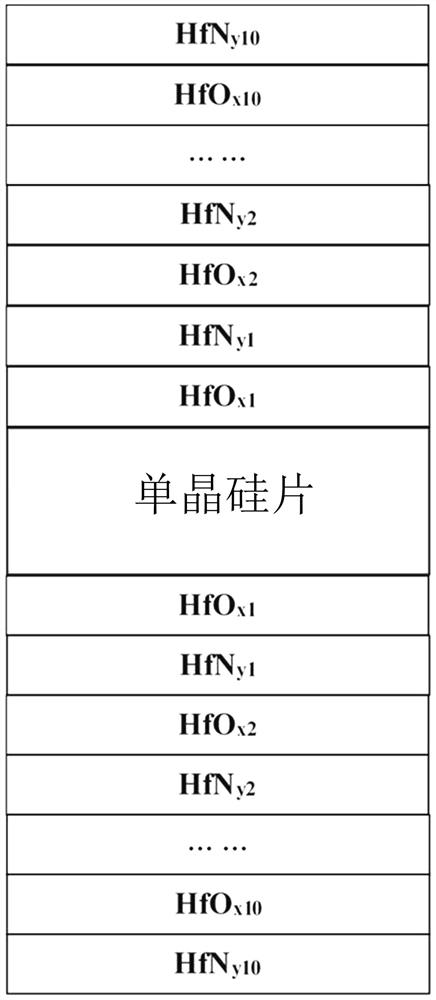

[0027] See attached picture. A schematic diagram of a typical monocrystalline silicon passivation contact structure is shown in figure 1 As shown, 10 layers of HfO were deposited on the front and back of the single crystal silicon wafer respectively x / HfN y , where each layer of HfO x or HfN y The thickness is 3nm, x is the ratio of Hf atoms to O atoms, and y is the ratio of Hf atoms to N atoms. Passivation of composition graded hafnium oxide-hafnium nitride multilayer film / single crystal silicon / composition graded hafnium oxide-hafnium nitride multilayer film prepared by reactive magnetron sputtering method on single crystal silicon substrate contact, in order to reduce defects in the film, followed by annealing at a temperature of 600-700°C. Compared to the tunnel oxide passivation contact, the saturation current density (J 0 ) and contact resistivity (ρ c ) can be significantly reduced.

[0028] The preparation method of the monocrystalline silicon passivation cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com