A kind of silicon rod cutting method

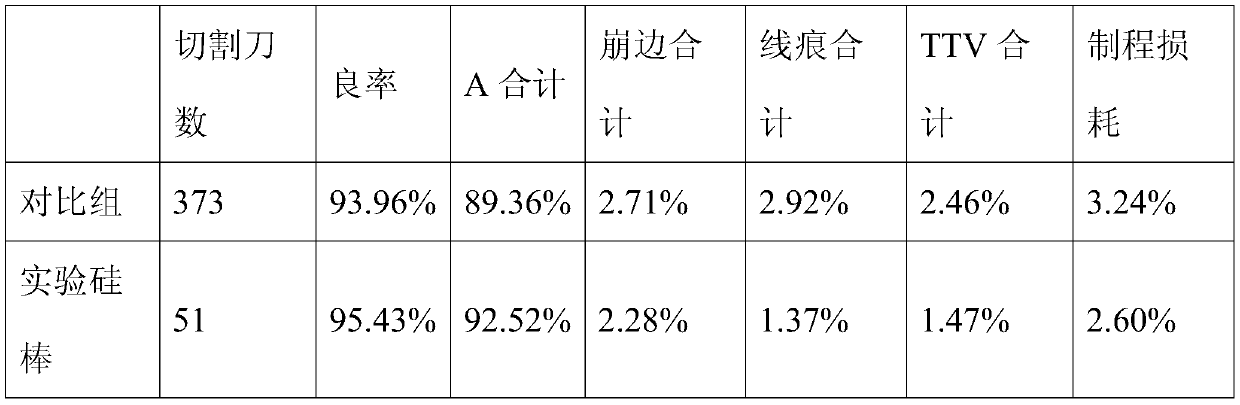

A cutting method and a technology of silicon rods, which are applied in the field of solar cells, can solve problems such as chipping, process loss, and the production cost of cells that affect the yield of silicon wafers, so as to improve the yield rate, increase the fracture resistance, reduce the generation and extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

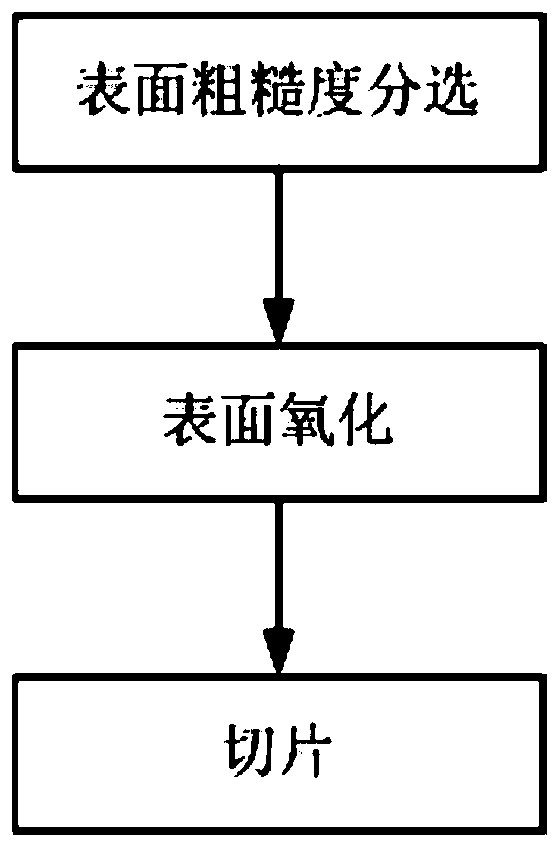

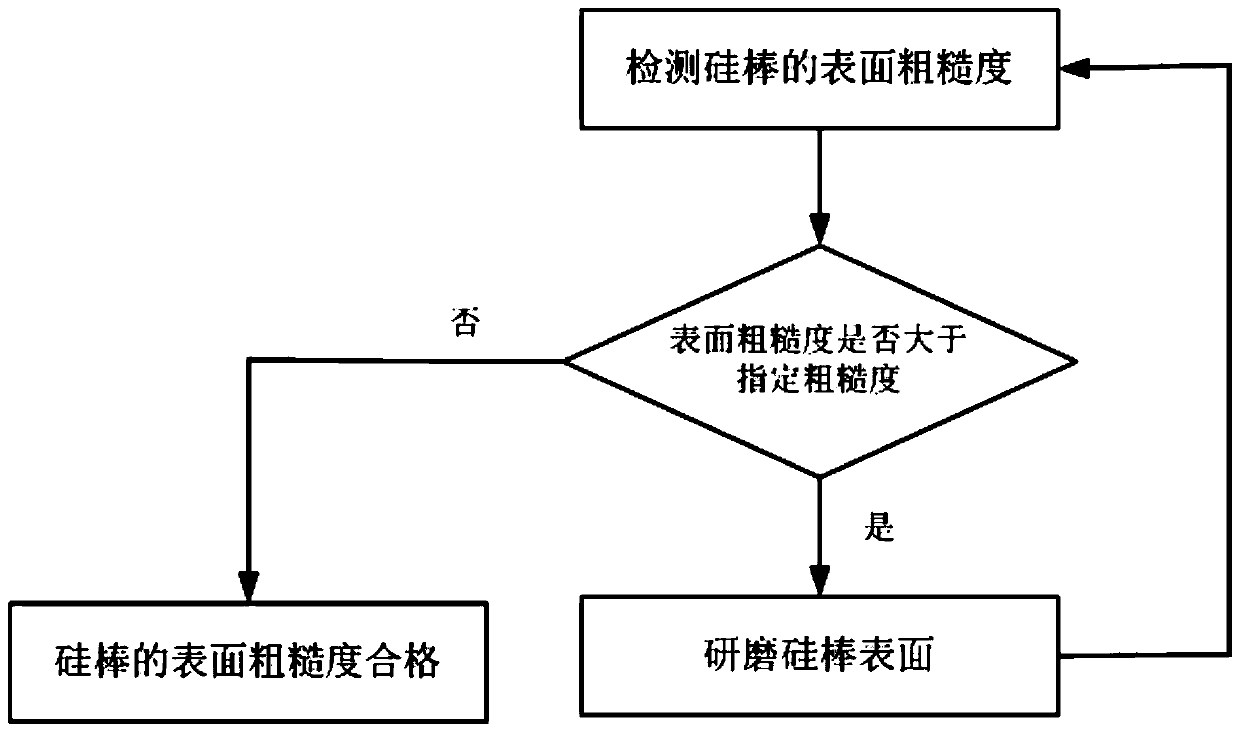

[0026] like figure 1 As shown, this embodiment provides a method for cutting a silicon rod. The silicon rod is sliced after surface oxidation treatment. The surface of the silicon rod is oxidized before slicing, so that a dense oxide film is formed on the surface of the silicon rod. The oxide film can repair the defects on the surface of the silicon rod, and the hardness of the oxide film is low, which can protect and buffer the silicon rod. It plays the role of passivation, thereby reducing the generation and expansion of surface cracks, and improving the fracture resistance of silicon rods. During the slicing process, the force of diamond wire cutting is not enough to cause chipping and silicon drop And other defects, reduce process loss, reduce the proportion of silicon wafer chipping, and improve the yield of processed silicon wafers.

[0027] The surface oxidation of silicon rods can be oxidation of silicon rods in strong oxidizing solution or gas, or high temperature ...

Embodiment 2

[0043] This embodiment provides a method for cutting silicon rods, which is substantially the same as the method for cutting silicon rods in Embodiment 1. The difference from Embodiment 1 is that in this embodiment, the silicon rods are oxidized in a strong oxidizing gas.

[0044] Specifically, the silicon rod 5 can also be oxidized in a strong oxidizing gas such as ozone. When silicon rod 5 is oxidized in ozone, the concentration of ozone can be 1.2-1.5mg / L, for example can be 1.2mg / L, 1.3mg / L, 1.4mg / L, 1.5mg / L, wherein, the present embodiment The concentration of ozone in the medium is preferably 1.5mg / L. The oxidation time of the silicon rod 5 is 10min-60min, and the oxidation temperature is 10°C-200°C. Specifically, the oxidation time of silicon rod 5 can be 10min, 15min, 20min, 30min, 40min, 50min, 60min, and the oxidation time is preferably 15min; the oxidation temperature can be 10°C, 30°C, 50°C, 70°C, 90°C, 110°C, 130°C, 150°C, 170°C, 190°C, 200°C, the oxidation temp...

Embodiment 3

[0047] This embodiment provides a silicon rod cutting method, which is roughly the same as the silicon rod cutting method in Embodiment 1. The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, the silicon rod is in air or oxygen. high temperature oxidation.

[0048] Silicon rod 5 can be placed in air or oxygen for high-temperature oxidation. The higher reaction temperature can compensate for the oxidation of air or oxygen. When silicon rod 5 is oxidized at high temperature in air or oxygen, the oxidation time of silicon rod 5 is 0.01min -60min, the oxidation temperature is 600°C-1400°C. Specifically, the oxidation time of silicon rod 5 can be 0.01min, 10min, 20min, 30min, 40min, 50min, 60min, and the oxidation time is preferably 30min; the oxidation temperature can be 600°C, 680°C, 760°C, 840°C, 920°C , 1000°C, 1080°C, 1160°C, 1240°C, 1320°C, 1400°C, the oxidation temperature is preferably 840°C.

[0049] Silicon rods are subjected to high-temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com