Ventilation air bag and preparation method and mold thereof

A technology of airbags and molds, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of high production cost, many airbag components, complex structure, etc., achieve good airtightness, simplify the production process, and simplify the structure of the airbag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

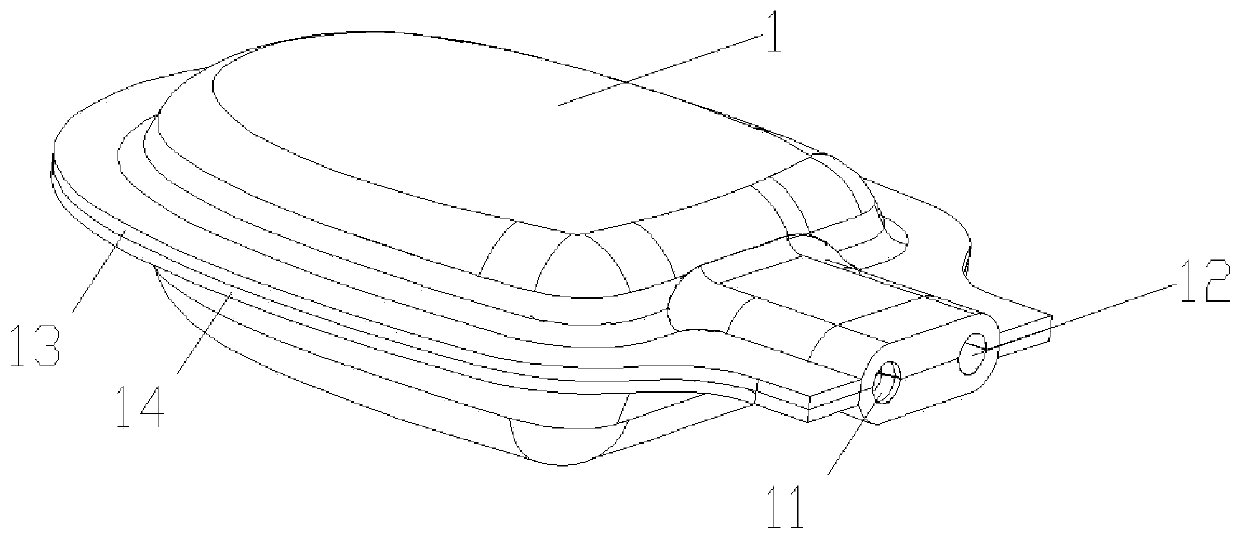

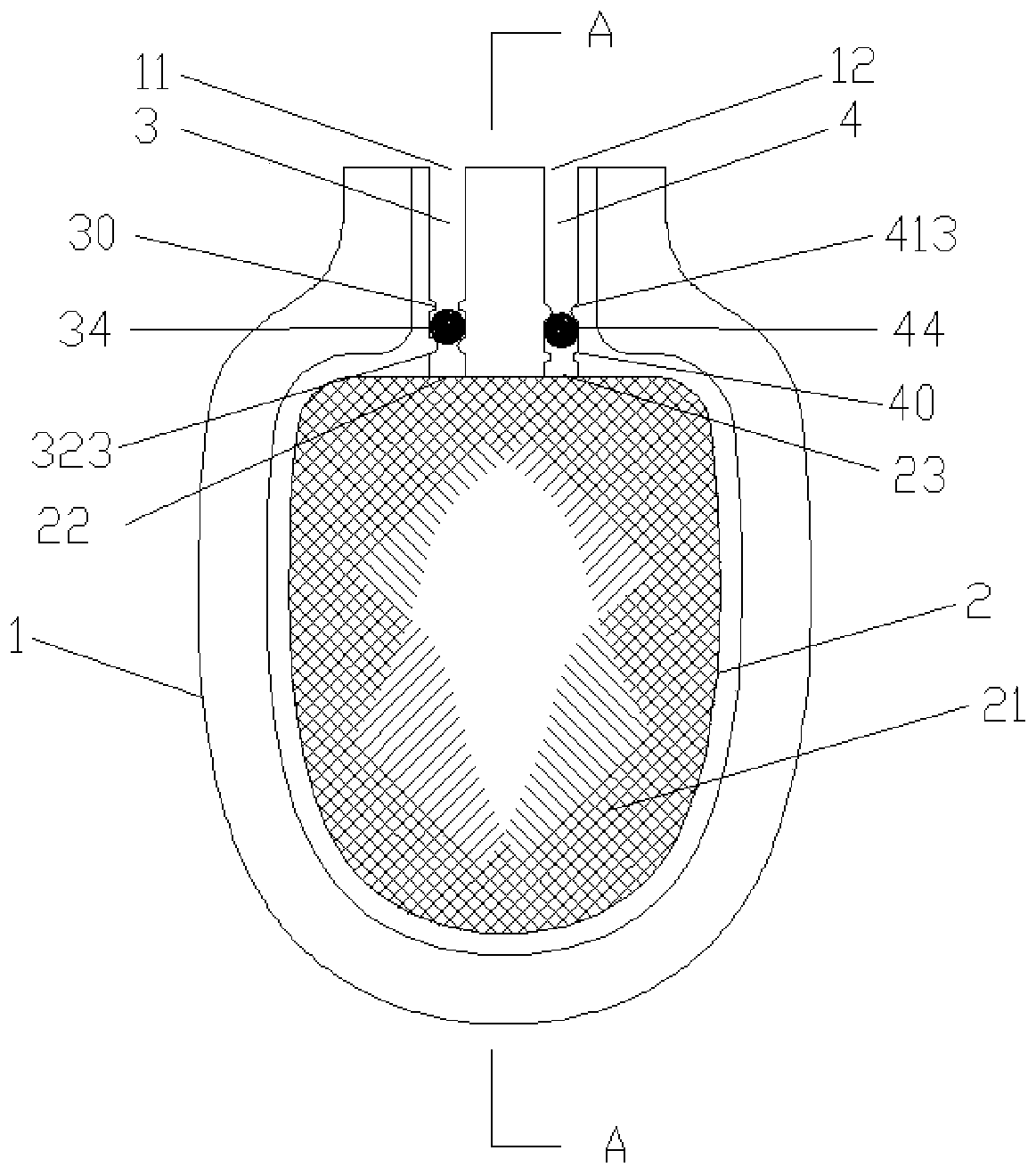

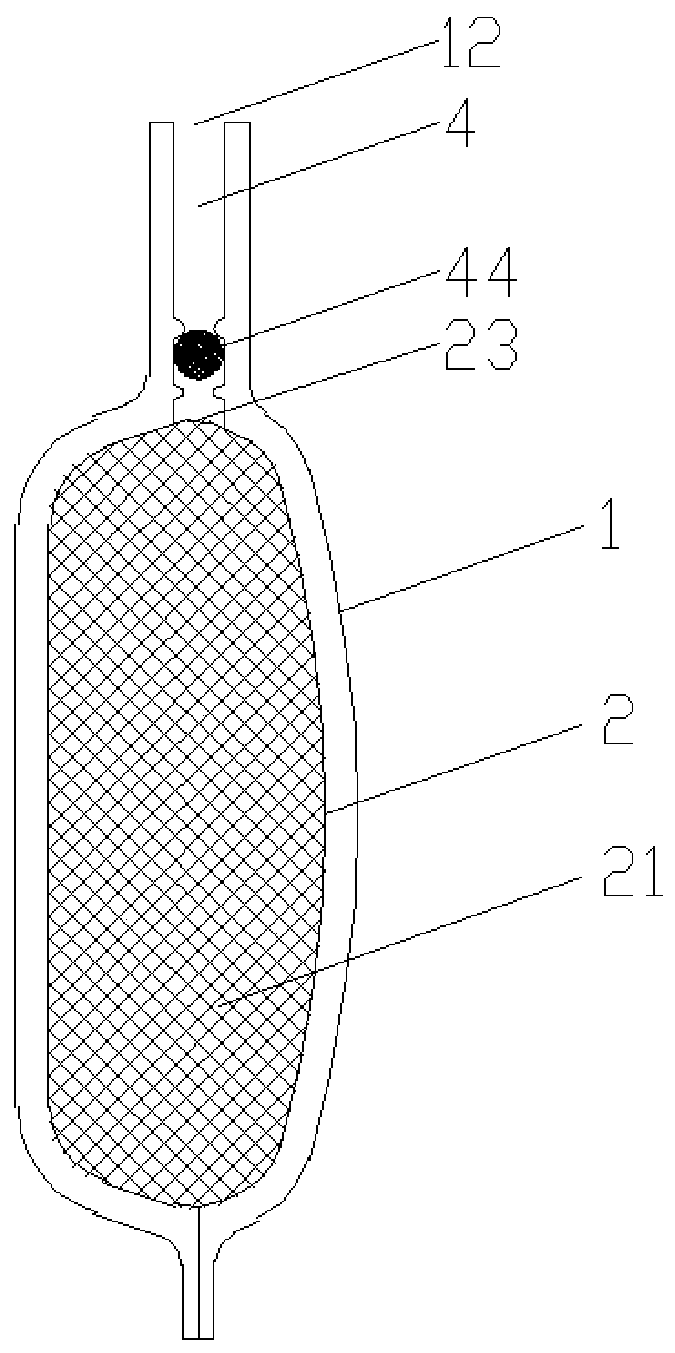

[0037] see Figure 1-9 As shown, the present invention relates to a ventilation airbag, including an airbag body 1, the airbag body 1 is made of rubber, the airbag body 1 includes an airbag upper sheet 13 and an airbag lower sheet 14, and the airbag body 1 is provided with a Air cavity 2, the air-containing inner cavity 2 is provided with breathable support fillers 21, such as sponges, leaves, etc., the front end of the airbag body 1 is provided with an air inlet 11 and an air outlet 12, and the air-containing inner cavity 2 It has an inlet 22 and an outlet 23, and a one-way air intake channel 3 communicating with the air-containing inner cavity 2 is provided between the air inlet 11 and the inlet 22 of the air-containing inner cavity 2, and between the air outlet 12 and the outlet 23 of the air-containing inner cavity 2 There is a one-way outlet flow channel 4 communicating with the air-containing inner cavity 2. The airbag body 1, the one-way inlet flow channel 3 and the one...

Embodiment 2

[0056] The difference between Embodiment 2 and Embodiment 1 is that the structures of the inlet runner 3 and the outlet runner are different, and the structure of the inlet runner mold core and the outlet runner mold core are different.

[0057] In the second embodiment, the air intake channel 3 includes a first air intake section 31, a second air intake section 32 and a first interface 33 communicating with the first air intake section 31 and the second air intake section 32. The air inlet section 32 is provided with a first ball 34 that opens or closes the first interface 33, and the outlet flow channel 4 includes a first air outlet section 41, a second air outlet section 42 and a first air outlet section 41 and a second air outlet section 42 connected to each other. The second interface 43 of the section 42, the first air outlet section 41 is provided with a second ball 44 for opening or closing the second interface 43.

[0058]Preferably, the first air intake section 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com