Sheath blowing machine

A sheathing machine and sheathing technology, which are applied to household components, household appliances, other household appliances, etc., can solve problems such as difficulty in passing through sheaths, limiting cable processing efficiency, and limiting processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

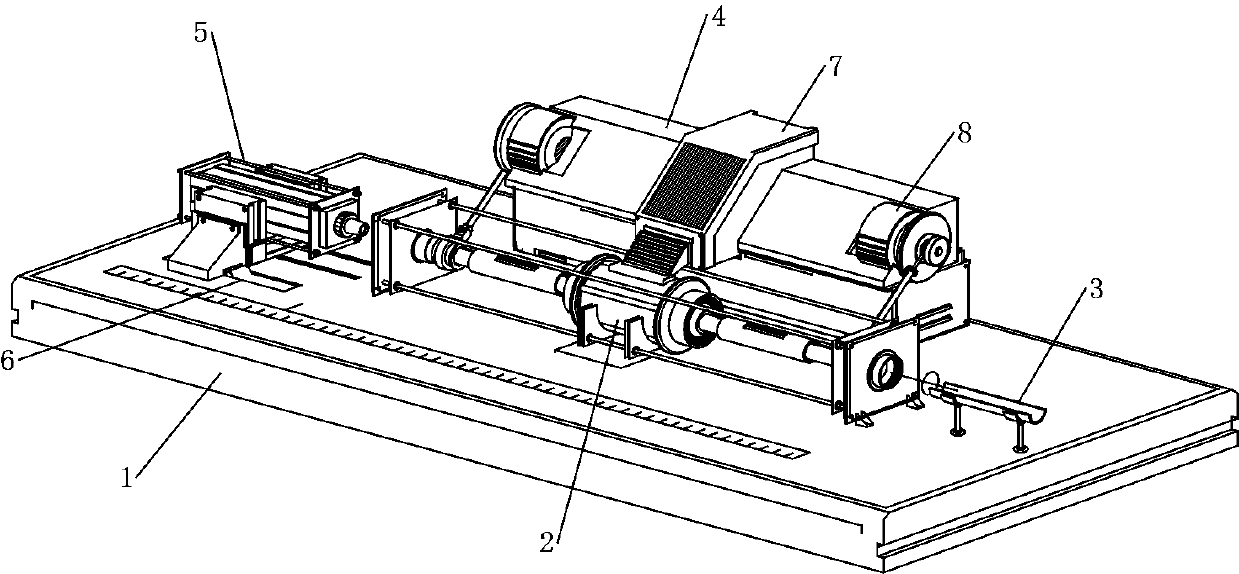

[0038] This embodiment comprises that above-mentioned main cabinet 4 contains all mechanical control equipments, and this sheath blowing machine is controlled according to the PLC system setting program, after the power supply box 35 is connected to the on-site power supply by the operator during production, start the machine through the control panel 33 and start the machine. operate.

[0039] The input end of the connection panel 34 is electrically connected to the connection cable 12, the drive motor 19 and the output end of the displacement motor 41;

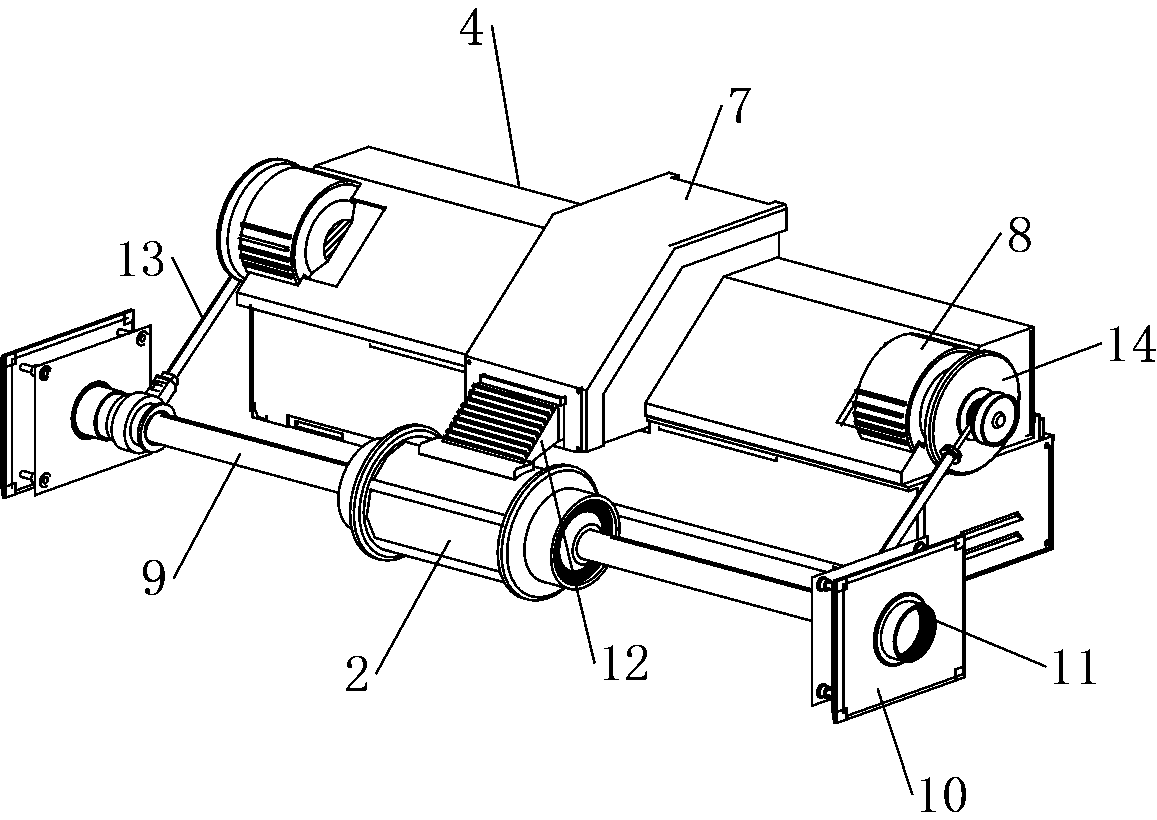

[0040] A sheath sleeve 9 is plugged into the left and right ends of the expansion cylinder seat 2, the sheath sleeve 9 communicates with the inner tube 30, a sleeve 15 is sleeved in the middle of the sheath sleeve 9, and the sheath sleeve 9 is in addition One end is sleeved with a sealing plug 16, and the outer side of the sealing plug 16 is adjacent to a handle seat 10, and the middle opening of the handle seat 10 is provid...

Embodiment 2

[0044] On the basis of the above-mentioned embodiment, the production personnel inserts the sheath into the plug opening 11 along the surface of the handle seat 10 at the left end, and inserts it into the sheath tube 9 at the left end. As the sheath goes deeper, the other end of the sheath will pass through the expansion cylinder seat 2 Insert in the right end sheath casing 9;

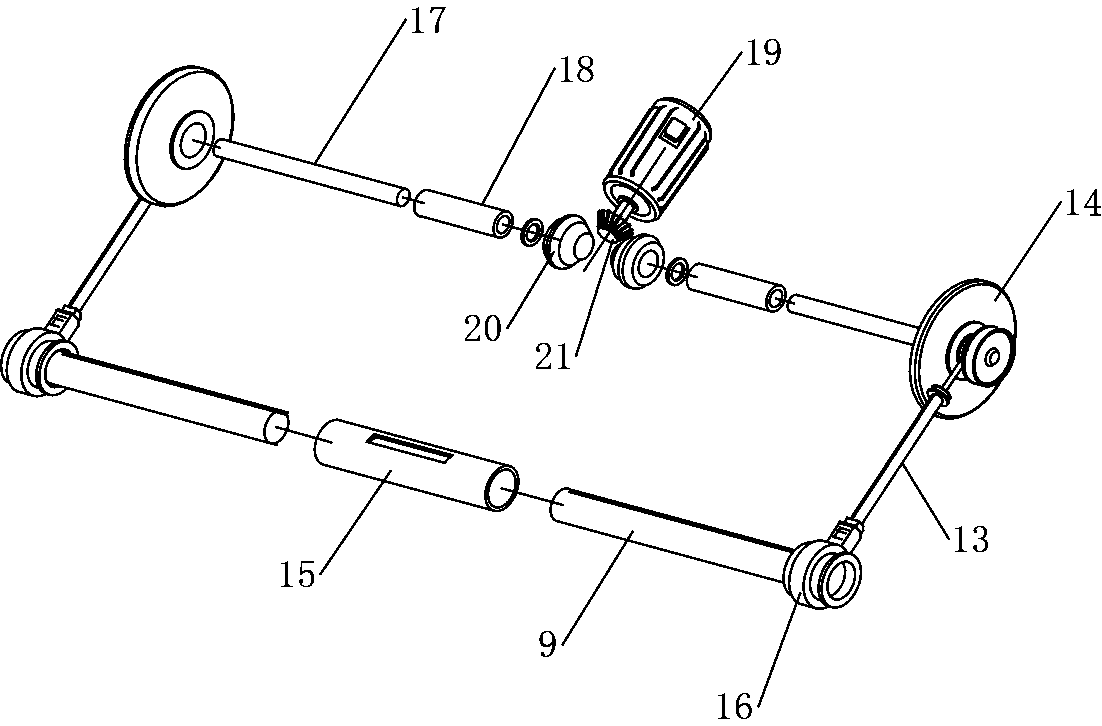

[0045] At this time, the main engine 7 controls the drive motor 19 to brake, and the drive motor 19 rotates forward and drives the right-hand transmission shaft 17 to rotate forward through the crankshaft bevel gear 21 and the bevel gear 20, and the left-hand transmission shaft 17 is reversed. At this time, the right-hand transmission shaft 17 The shaft joint 18 and the connecting gear 24 will be used to drive the right-end shaft seat plate 14 to be driven, and the shaft core 23 will be rotated forward along the bearing 25 synchronously. Roll up and pull the other end located in the sealing plug 16. Af...

Embodiment 3

[0048] After the above-mentioned embodiment, the main engine 7 controls the displacement motor 41 to brake, and the displacement motor 41 drives the threaded shaft 39 to be driven, and the ball screw 40 threadedly connected with the threaded shaft 39 will carry out lateral translation along with the threaded shaft 39 screwing in direction, And synchronously drive the rail seat 36 to move along the track groove 6. After the rail seat 36 moves to the right end limit position along the track groove 6, the right end of the cylinder 5 will insert the insertion head 38 into the left end inlet and outlet plug port 11, and pass through the cylinder 5 along the inlet and outlet plug port. 11. The sheath casing 9 is inflated into the sheath.

[0049] An inner tube 30 is provided through the middle of the inner side of the expansion cylinder seat 2, and a strain patch 31 is distributed circularly on the outer middle of the inner tube 30. The cable 12 is electrically connected to the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com