Height-adjustable floating roof pillar with wedge surface sealing structure

A sealing structure and adjustable technology, which is applied in the direction of container, packaging, transportation and packaging, etc., can solve the problems of tank leakage and insufficient sealing effect, and achieve the effect of improving utilization rate, reducing sinking accidents, and safe and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

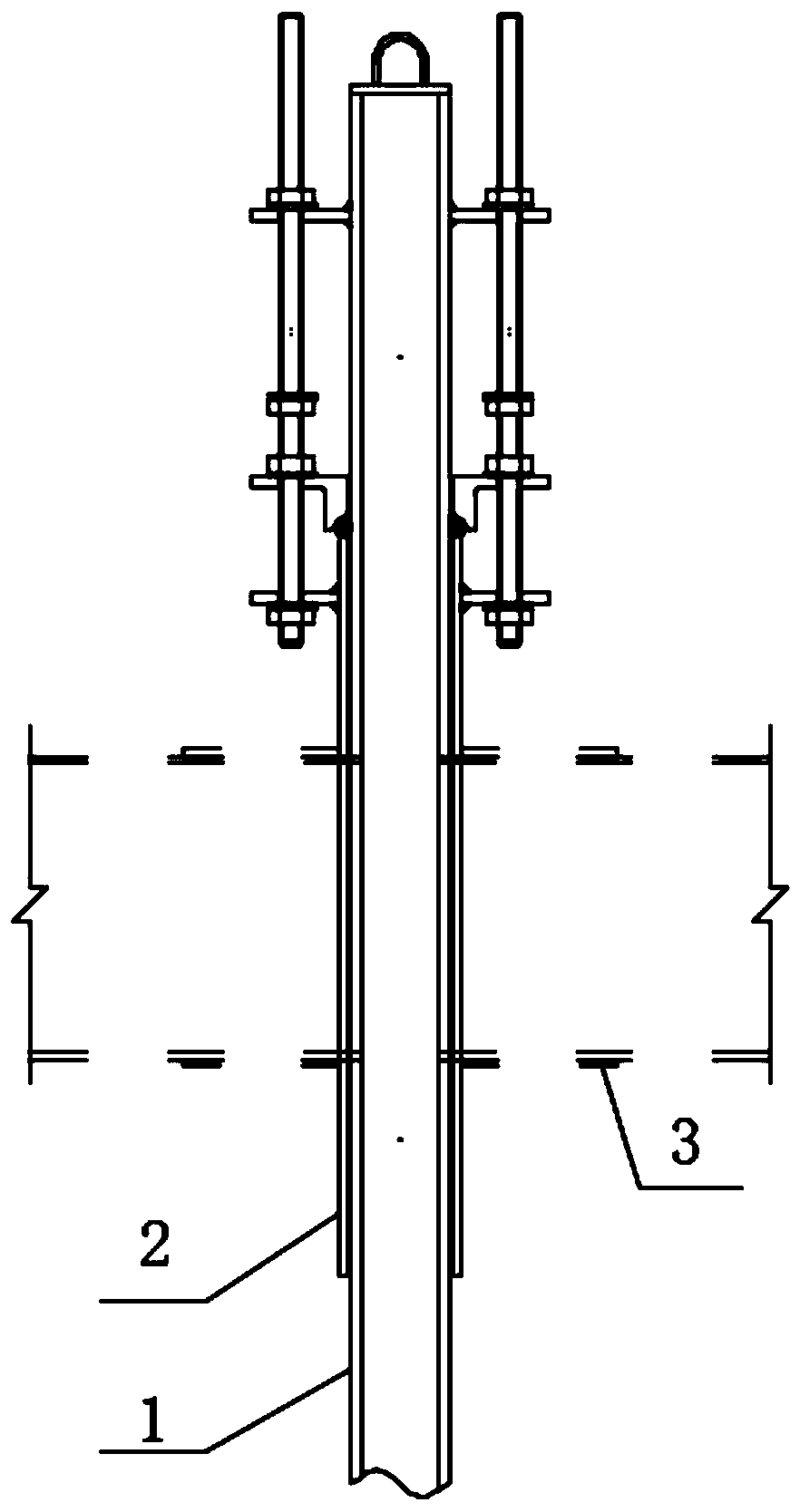

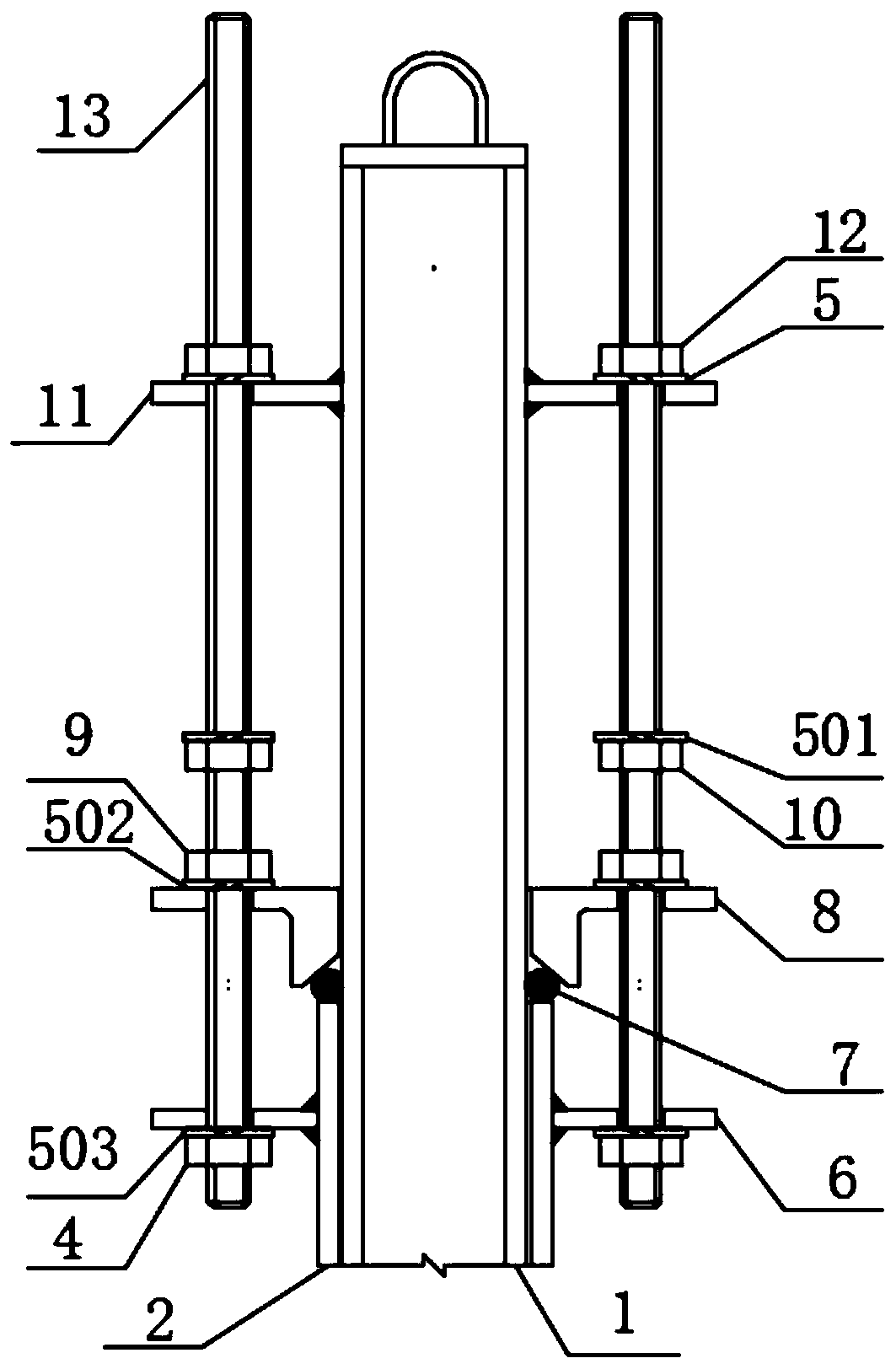

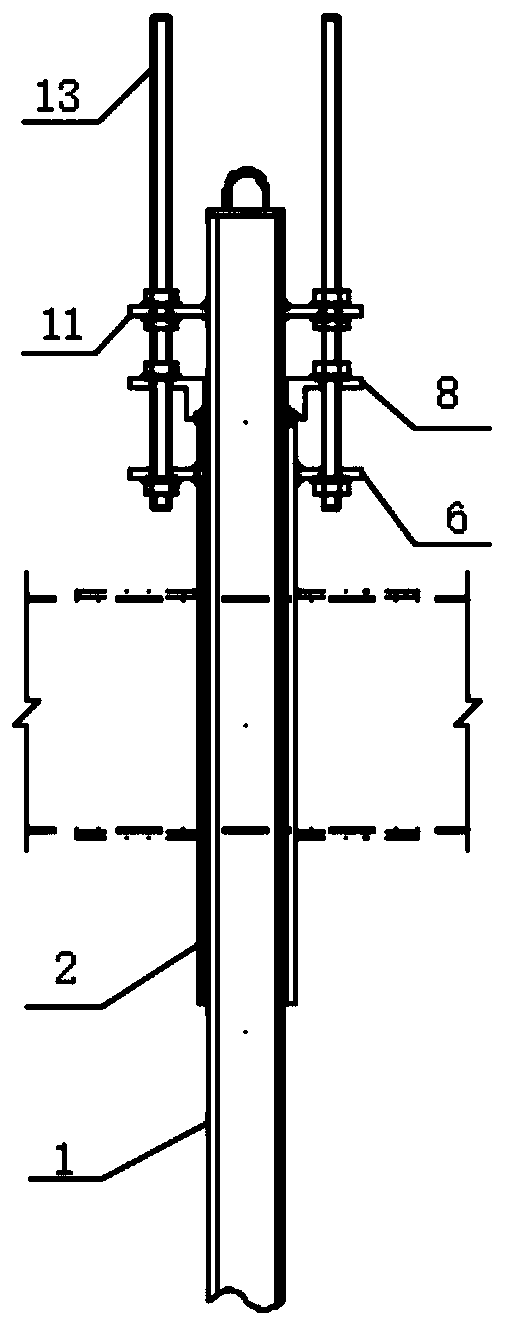

[0030] Such as Figure 1~4 As shown, this embodiment provides a technical solution: a floating roof pillar with an adjustable height and a wedge surface sealing structure, including a pillar 1, a casing 2, a floating roof 3 and an adjustment assembly. The adjustment assembly is used to adjust the height of the pillar 1. Height, the pillar 1 passes through the sleeve 2, the adjustment assembly is arranged outside the sleeve 2, the floating roof 3 is welded to the sleeve 2, and the floating roof pillar rises and falls through the floating roof 3 with the change of the medium liquid level in the storage tank.

[0031...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com