Washing additive release device

A technology for feeding devices and downpipes, which can be applied to washing devices, other washing machines, textiles and papermaking, etc., and can solve problems affecting the quality of washing liquid, affecting the user experience, and flowing out of the water box, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

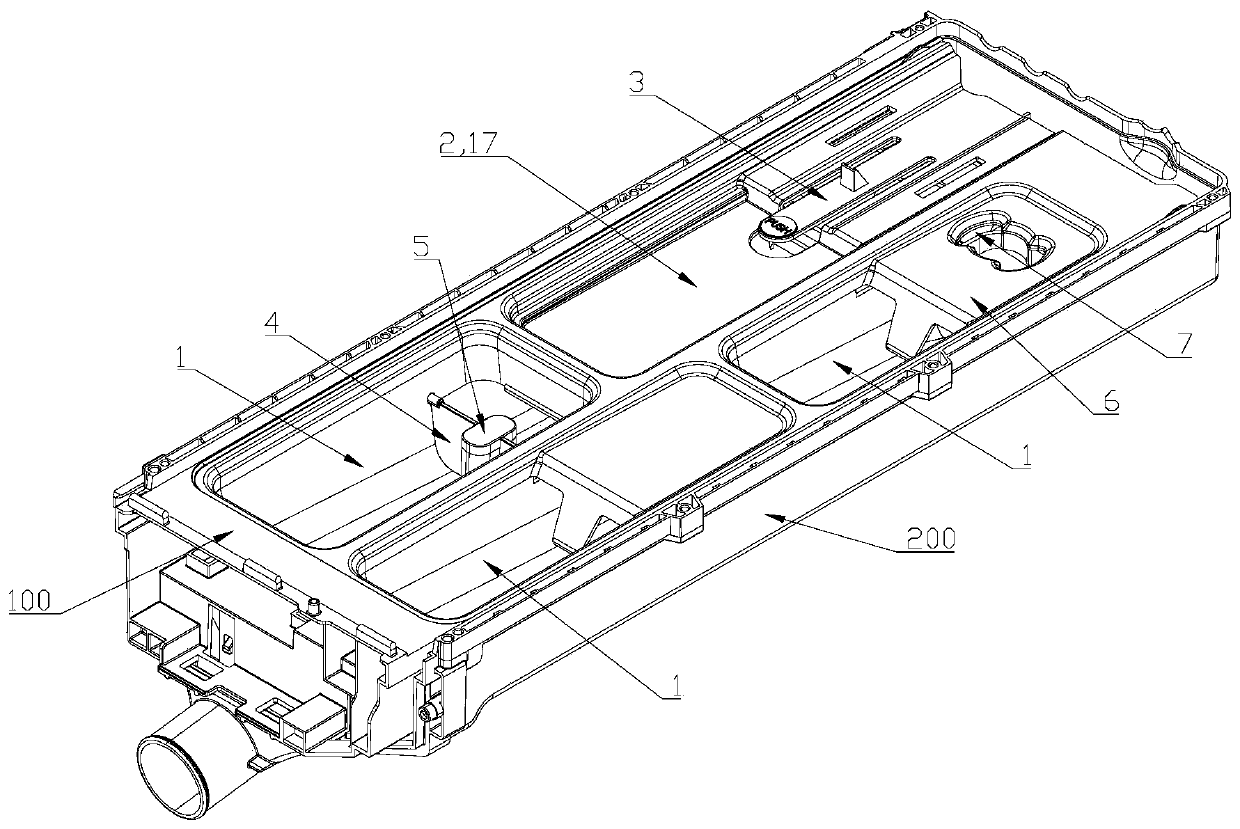

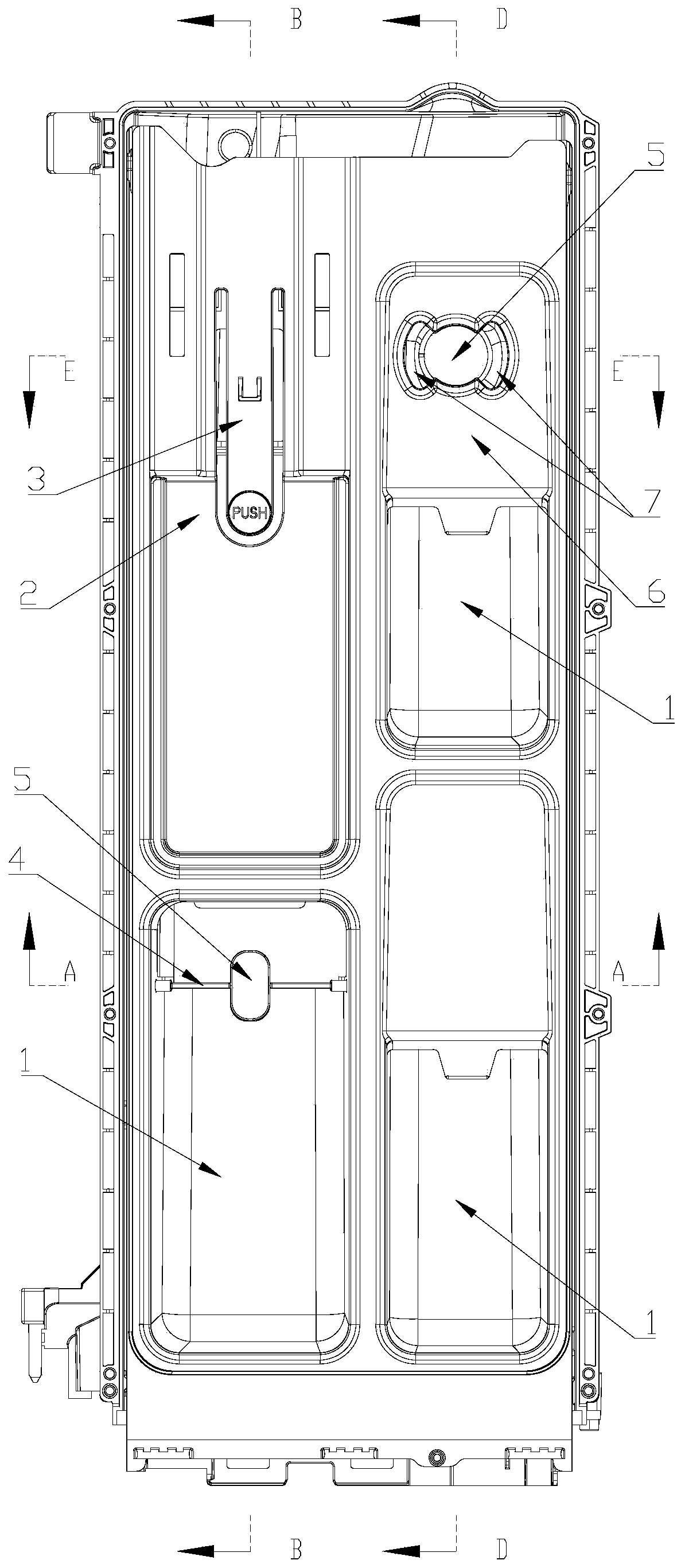

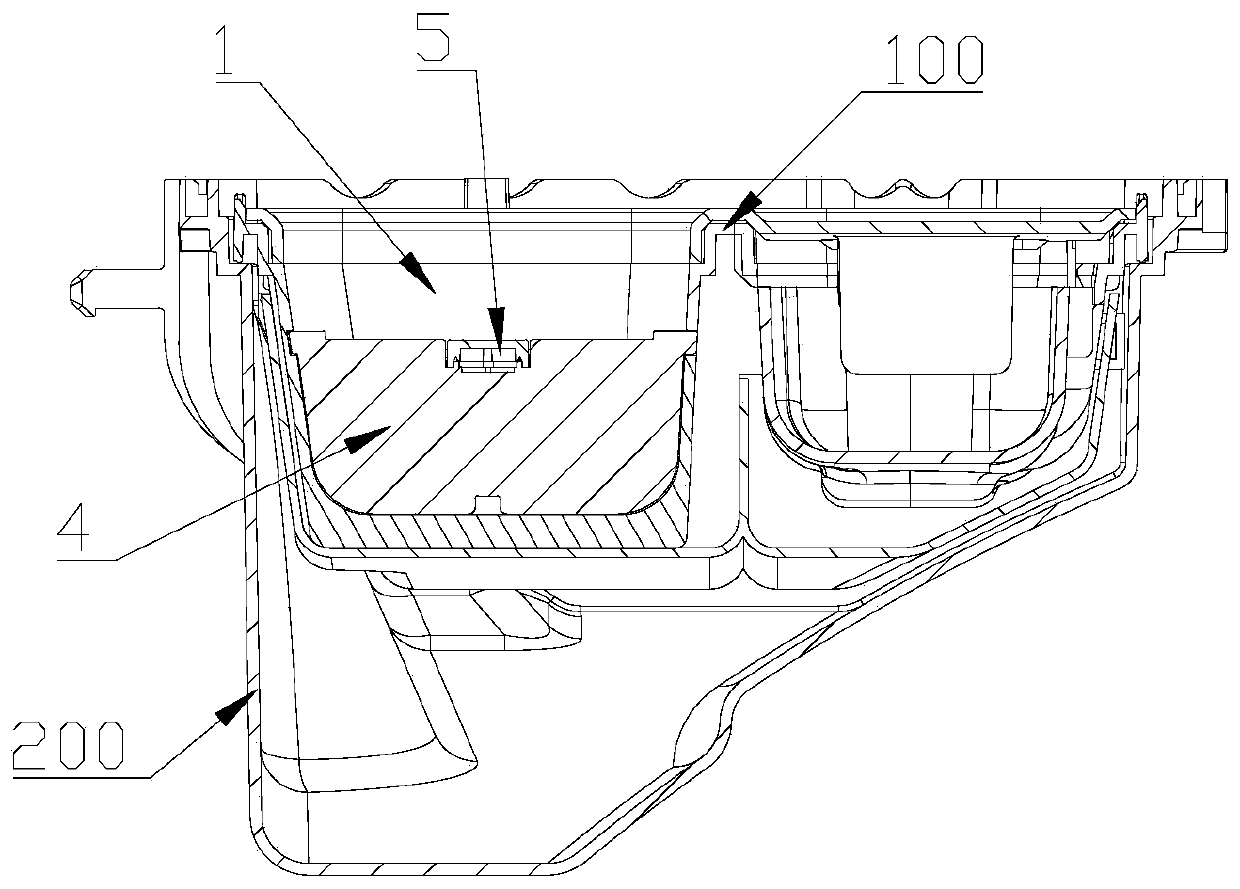

[0049] Such as Figure 1 to Figure 14 As shown, this embodiment provides a washing dispensing device, including: a water box 200, in which is installed a dispensing box 100 for dispensing detergent and / or washing powder; preferably, the dispensing box 100 may be The drawn correspondingly is inserted into the water box 200. The dropping box 100 is provided with at least one dropping cavity 1, and the bottom of the dropping cavity 1 is provided with a water outlet 11 communicating with the water box 200. The washing machine flows into the dropping cavity 1 all the way, so that the detergent added in the dropping box 100, and / Or the washing powder is flushed into the water box 200 from the water outlet 11 through the action of the water flow. A baffle 4 is installed in the injection chamber 1 to block the flow of water to the water outlet 11. The baffle 4 is provided with a siphon column 5 connecting the two sides, so that the upstream side of the baffle 4 is injected from the in...

Embodiment 2

[0065] Such as Figure 8 to Figure 14 As shown, this embodiment provides a washing dispensing device, including: a water box 200, in which is installed a dispensing box 100 for dispensing detergent and / or washing powder; preferably, the dispensing box 100 may be The drawn correspondingly is inserted into the water box 200. The dropping box 100 is provided with at least one dropping cavity 1, and the bottom of the dropping cavity 1 is provided with a water outlet 11 communicating with the water box 200. The washing machine flows into the dropping cavity 1 all the way, so that the detergent added in the dropping box 100, and / Or the washing powder is flushed into the water box 200 from the water outlet through the action of the water flow. A baffle 4 is installed in the injection chamber 1 to block the flow of water to the water outlet 11. The baffle 4 is installed in the injection chamber 1 reversibly; the baffle is provided with a notch 10, and the water inlet of the water box ...

Embodiment 3

[0078] Such as Figure 1 to Figure 14 As shown, this embodiment provides a washing dispensing device, including: a water box 200, in which is installed a dispensing box 100 for dispensing detergent and / or washing powder; preferably, the dispensing box 100 may be The drawn correspondingly is inserted into the water box 200. The dropping box 100 is provided with downpipes 13 vertically running through the upper and lower sides. The upper and lower ends of the downpipe 13 are respectively located at the upper and lower wall surfaces of the dropping box 100 to drain the residual water on the top surface of the dropping box 100 to the dropping box. 100 below the bottom of the water box 200.

[0079] By setting a downpipe vertically through the dropping box of the dropping device, the water remaining on the top surface of the dropping box can flow to the bottom of the water box under the dropping box through the downpipe, avoiding the residual water on the top surface of the dropping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com