Prestressed concrete beam hogging moment area bridge structure and construction method thereof

A technology of negative bending moment area and bridge structure, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve problems such as difficulty in threading wires, corrosion of steel strands, long construction period, etc., and achieves simple and fast construction methods and reasonable and reliable stress , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

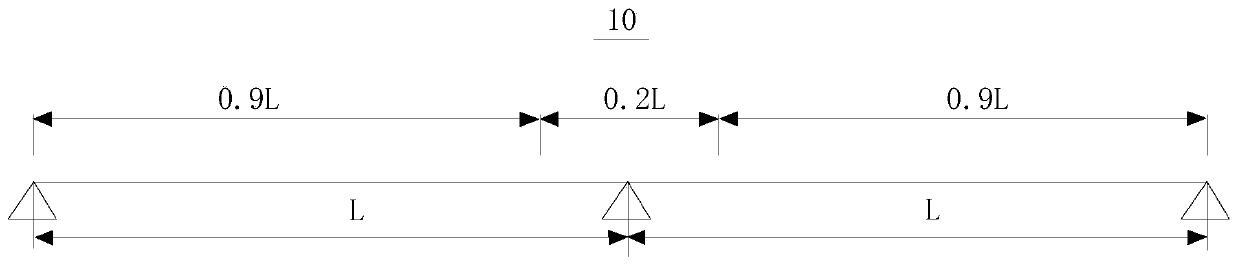

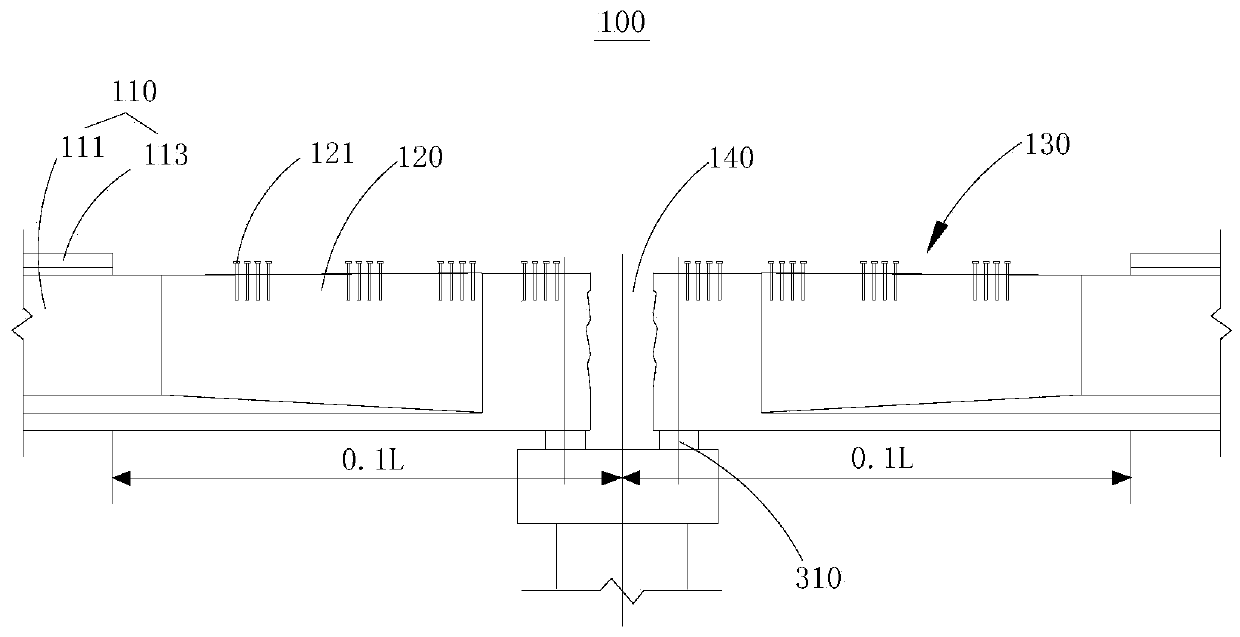

[0053] see Figure 1 to Figure 9 , the present embodiment provides a prestressed concrete beam bridge structure in the negative moment zone (hereinafter referred to as the bridge structure 10 ), which mainly includes a prefabricated T-beam 100 and a prefabricated bridge deck 200 .

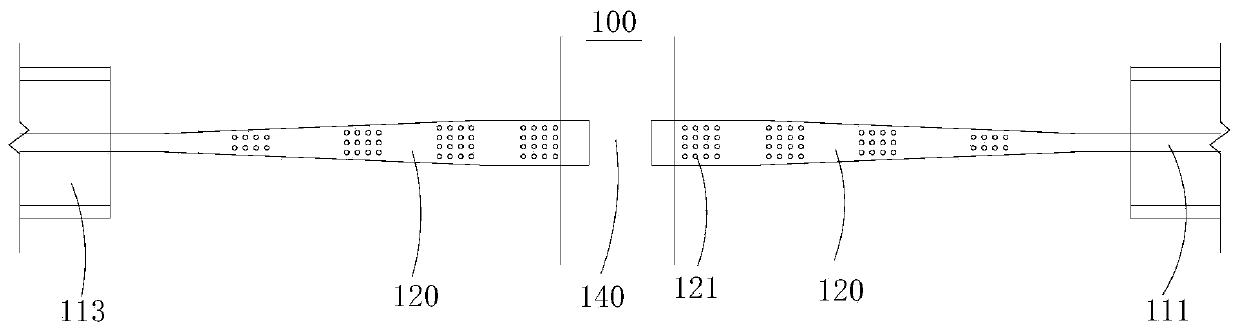

[0054] Among them, see figure 2 as well as image 3 , the prefabricated T-beam 100 includes a T-beam 110 installed in the positive moment region of the bridge structure 10 and a second beam rib 120 integrally formed with the T-beam 110 and installed in the negative moment region of the bridge structure 10, wherein the T-beam 110 And the second beam ribs 120 are arranged along the extending direction of the bridge structure. Wherein, the negative bending moment of the prefabricated T-beam 100 is within a range of 0.1L from the beam end of the second beam rib 120 .

[0055] It should be noted that the T-beam 110 is actually composed of the integrally formed first rib 111 and the wing plate 113 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com