Light steel keel composite wall body and implementation process

A light steel keel and composite wall technology, which is applied to walls, building components, thermal insulation and other directions, can solve the problems of complex manufacturing process of composite sandwich panels, no longer able to set external wall decoration layers, affecting the beauty of composite walls, etc. Superior fire resistance and moisture resistance, superior structural performance, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

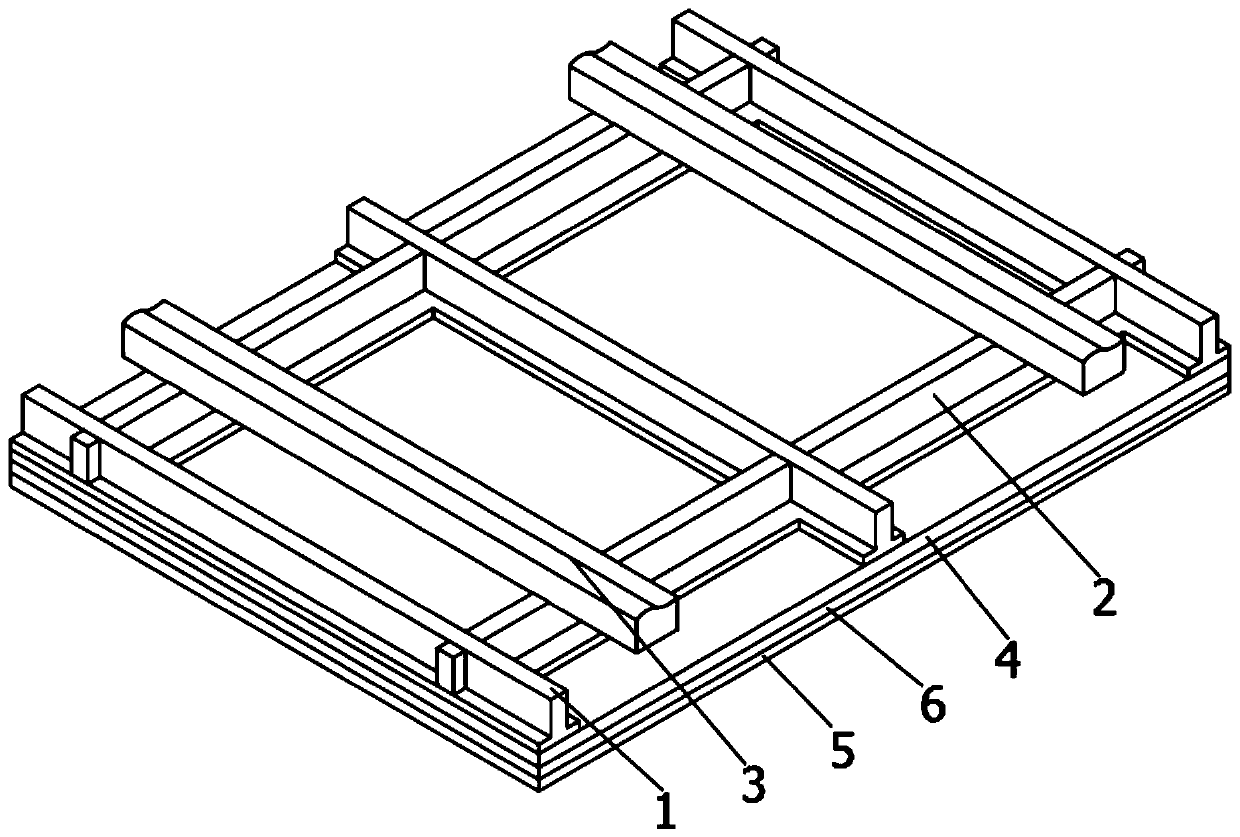

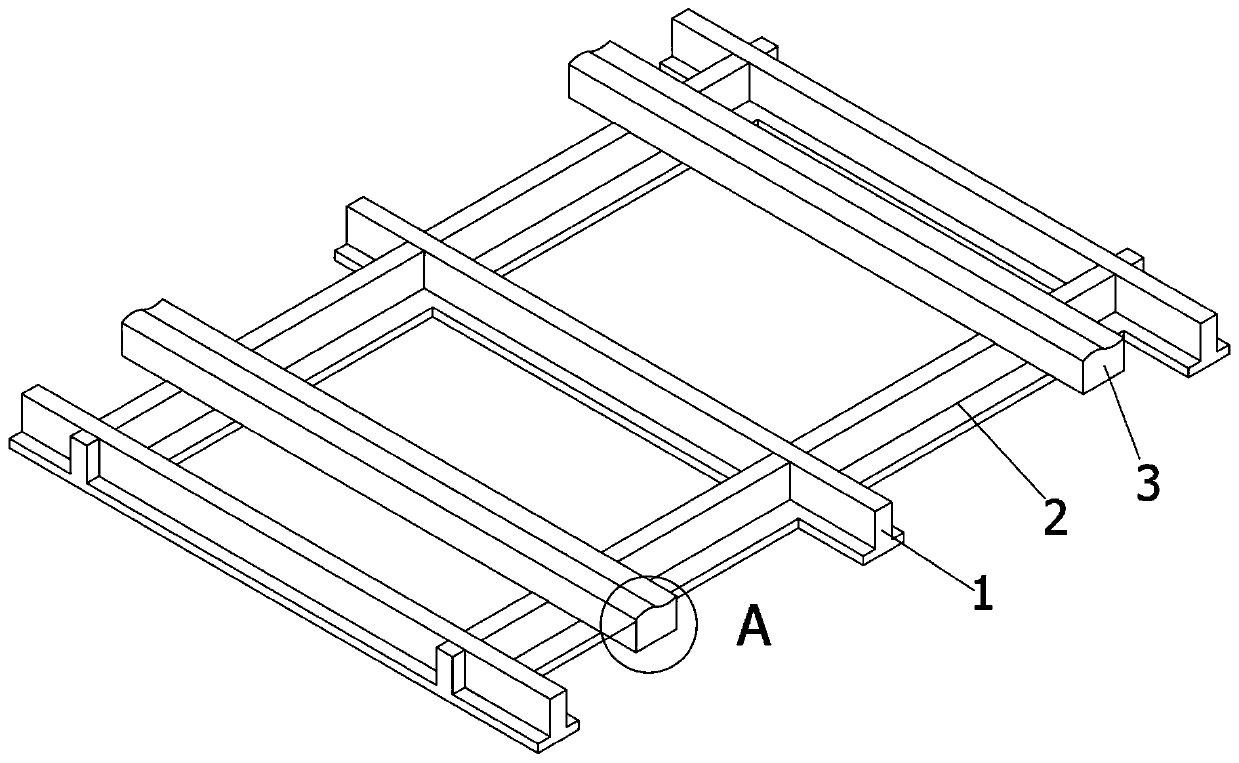

[0027] First of all, the original intention of the design of the present invention is to solve the problem that the cross-sectional shape of the keel currently used is a "C" shape, and by setting a composite sandwich panel outside the light steel keel frame, the composite wall has waterproof and fireproof properties, but The manufacturing process of the composite sandwich panel is relatively complicated, the production cost is high, and the exterior wall decoration layer cannot be installed, which affects the appearance of the composite wall; in order to change the shape of the keel to make it more suitable for the current wall market, the present invention Provided is a composite wall installed by using an S-shaped keel, thereby replacing the shortcomings of the existing composite wall structure, improving decorative performance, and facilitating installation and fixing of steel pipes.

[0028] In order to facilitate those skilled in the art to make this technical solution mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com