Novel steel bar planting structure and construction method thereof

A construction method and bar-planting technology, applied in the direction of structural elements, building components, building structures, etc., can solve the problems of large amount of engineering and low work efficiency, and achieve the effect of reducing operations, reducing safety hazards, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples.

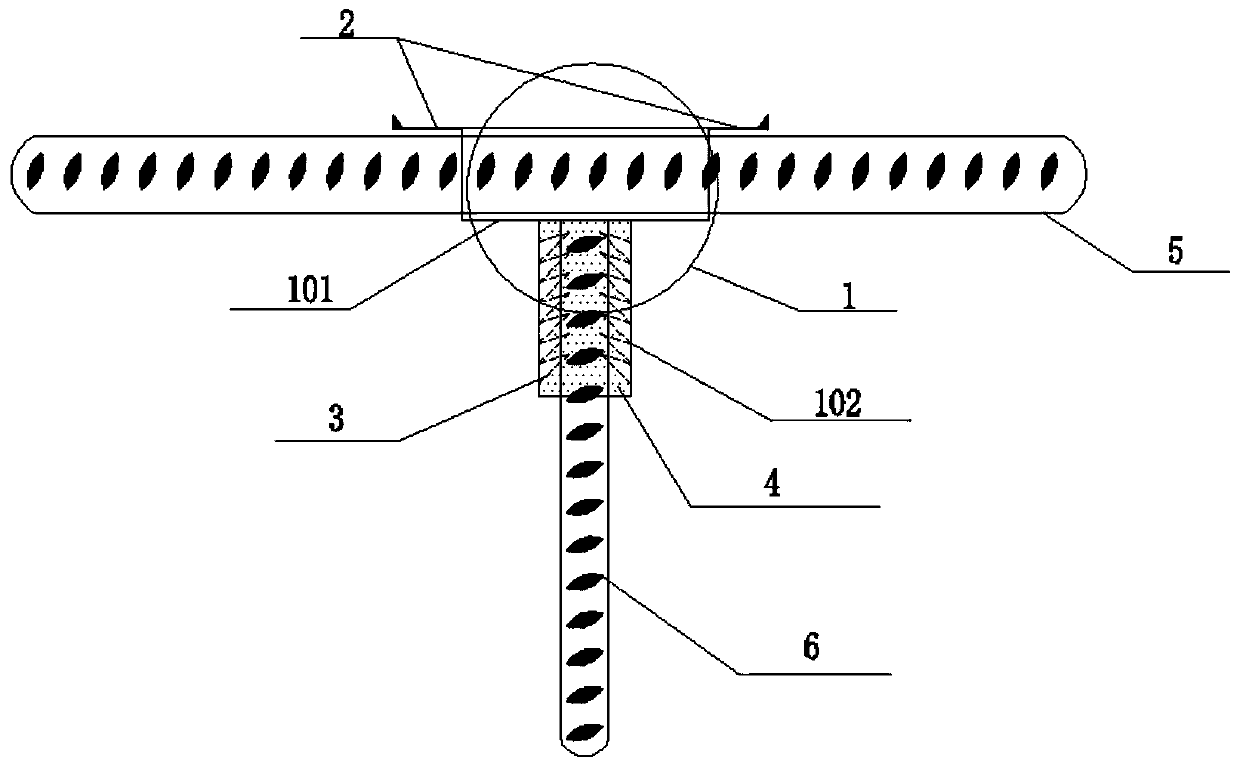

[0016] Such as figure 1 As shown, the implementation of the present invention provides a novel planting bar structure and construction method thereof, including a shell 1, a metal fixing piece 2, a metal chamfer 3, a metal adhesive 4, a main steel bar 5, and a steel bar to be planted 6, The shell 1 adopts a hollow design, and the shape of the shell 1 is T-shaped. The shell 1 is divided into a horizontal part 101 and a vertical part 102. The metal fixing piece 2 is located above the horizontal part 101 of the shell 1. The inner wall of the vertical part 102 of the shell 1 is provided with a metal chamfer 3, the main steel bar 5 is penetrated in the horizontal part 101 of the shell 1, the steel bar 6 to be planted is penetrated in the vertical part 102 of the shell 1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal length | aaaaa | aaaaa |

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com