Breather valve for spring braking air chamber and spring braking air chamber

A spring brake air chamber, breathing valve technology, applied in the direction of brake actuator, pipeline arrangement, gear transmission mechanism, etc., can solve the problems of difficult maintenance, complex internal breathing structure, etc., to achieve long service life, parts and components. Less usage and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

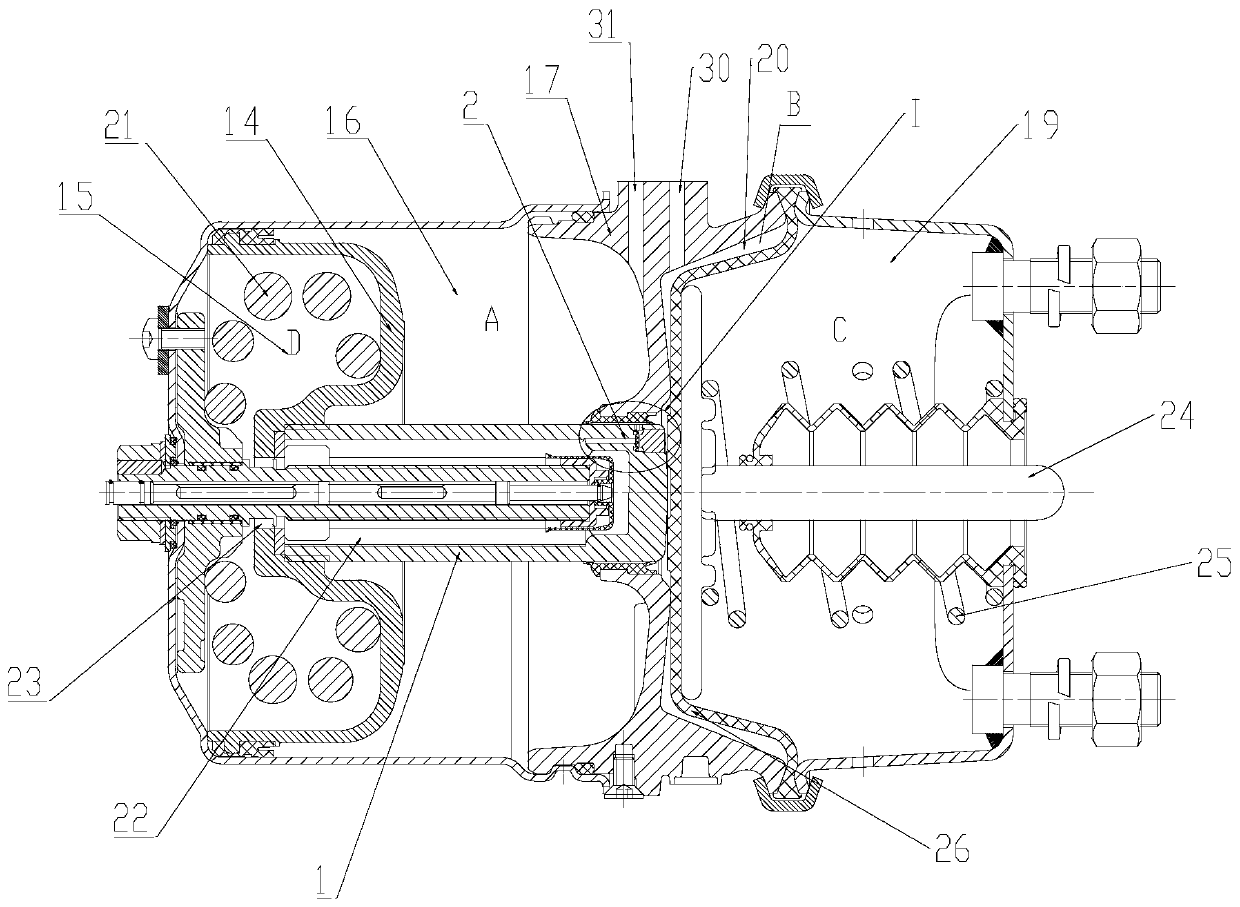

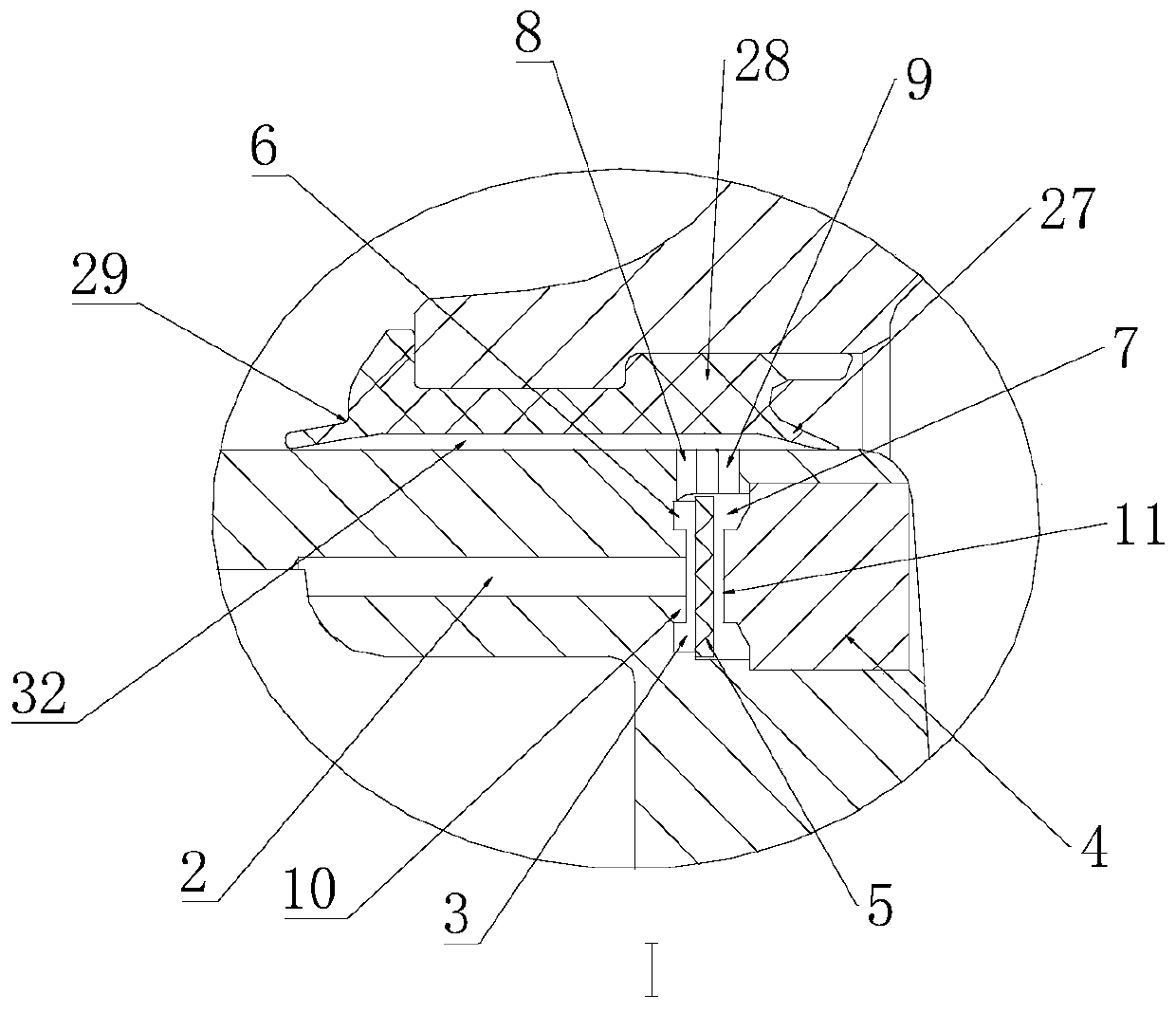

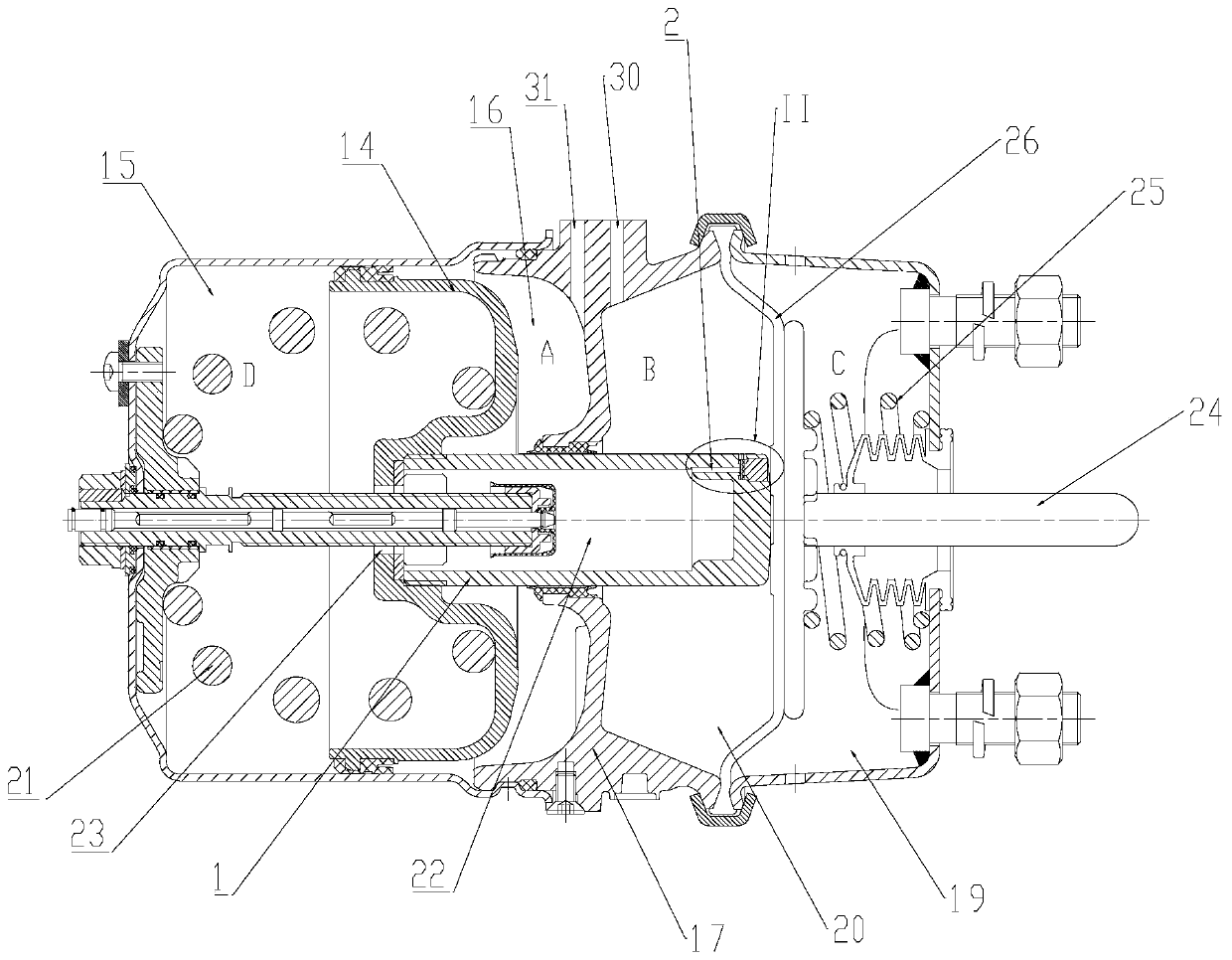

[0028] Such as Figure 1 to Figure 8 As shown, the breather valve used for the spring brake chamber, the breather valve structure is an internal breather structure. The breathing valve includes a piston rod 1, wherein the middle part of the piston rod 1 is a hollow structure, and a ventilation channel 2 is arranged in the piston rod 1, so the compressed air in the spring chamber D15 can enter the breathing channel through the hollow structure.

[0029] Wherein the breathing structure includes a breathing chamber 3 arranged in the piston rod 1 , specifically the breathing chamber 3 is arranged at the end of the piston rod 1 . One end of the breathing chamber 3 is provided with a plug 4, and the plug 4 is a detachable plug 4, so the processing method of the breathing chamber 3 is: a cavity is provided at one end of the piston rod 1, so that the cavity can be connected with the ventilation channel 2 Connected, and then place the valve plate 5 and install the plug 4.

[0030] It...

Embodiment 2

[0036] Such as Figure 1 to Figure 8As shown, this embodiment discloses a spring brake air chamber, and the spring brake air chamber includes the breathing valve described in Embodiment 1. The spring brake air chamber includes a parking chamber and a driving chamber, and a first piston 14 is arranged in the parking chamber, and the first piston 14 divides the parking chamber into a spring chamber D15 and a parking chamber A16, and also includes a valve body 17. The vehicle compartment and the driving compartment are located on both sides of the valve body 17. A diaphragm 26 is arranged in the driving compartment, and the diaphragm 26 divides the forming chamber into a spring chamber C19 and a driving chamber B20; Collision on the first piston 14, the first piston 14 is connected with the piston rod 1, the first piston 14 and the piston rod 1 move synchronously, and the middle part of the piston rod 1 is provided with a cavity 22, which is the hollow structure described in Embo...

Embodiment 3

[0044] The difference between this embodiment and Embodiment 1, Embodiment 2, and Embodiment 3 is that a first boss 12 is provided on the left side of the valve plate 5 , and a second boss 13 is provided on the right side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com