Automobile hub rim detection bench

A technology for automobile wheel hubs and testing platforms, applied in wheel testing, measuring devices, instruments, etc., can solve problems such as gauge wear, increased testing costs, affecting productivity and production efficiency, and achieve the effects of improving accuracy and reducing use and consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

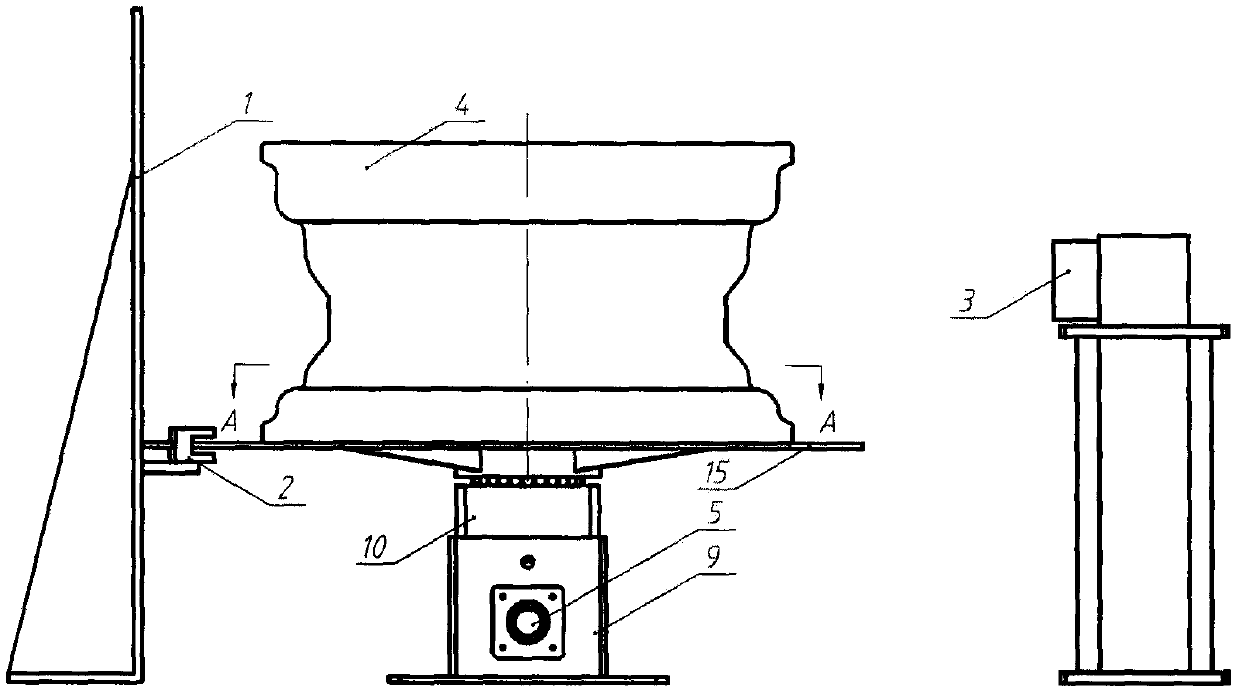

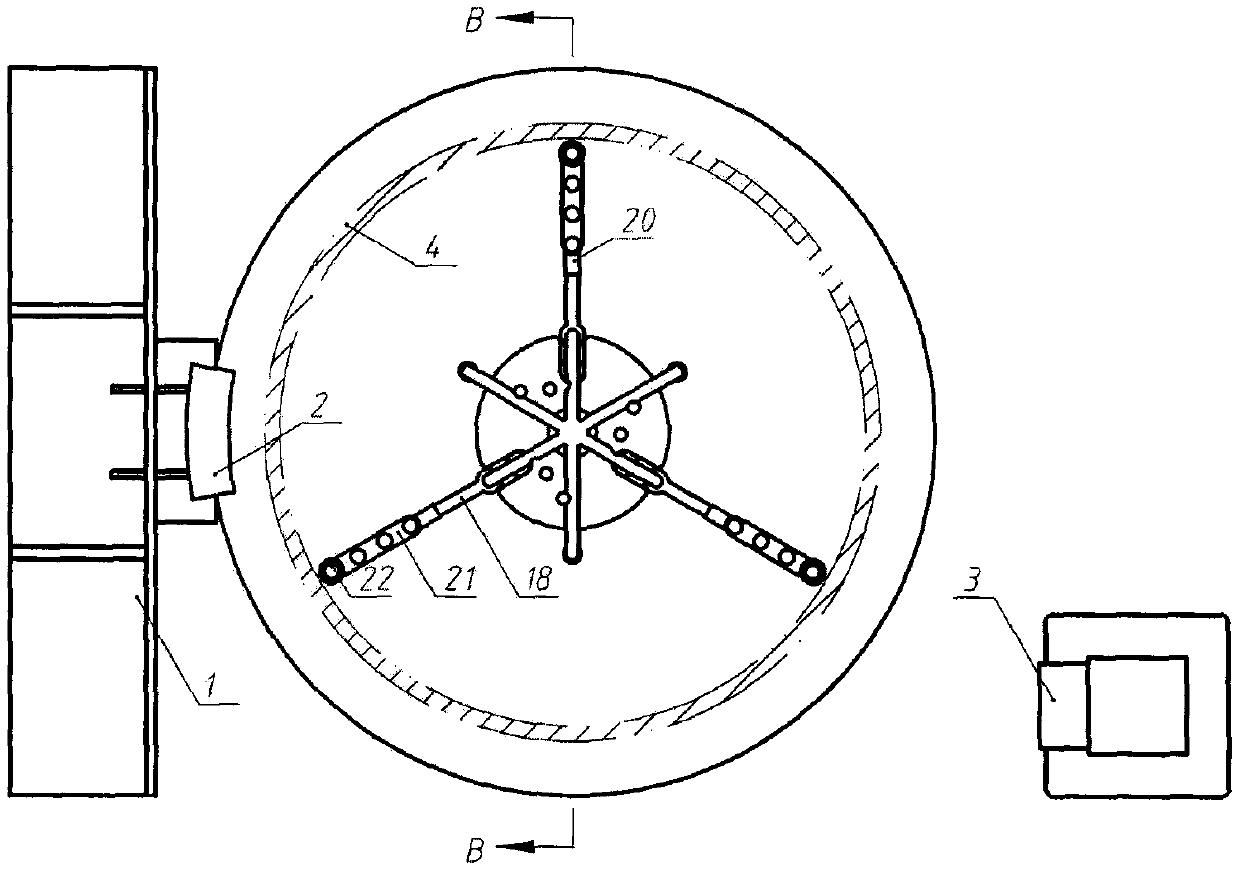

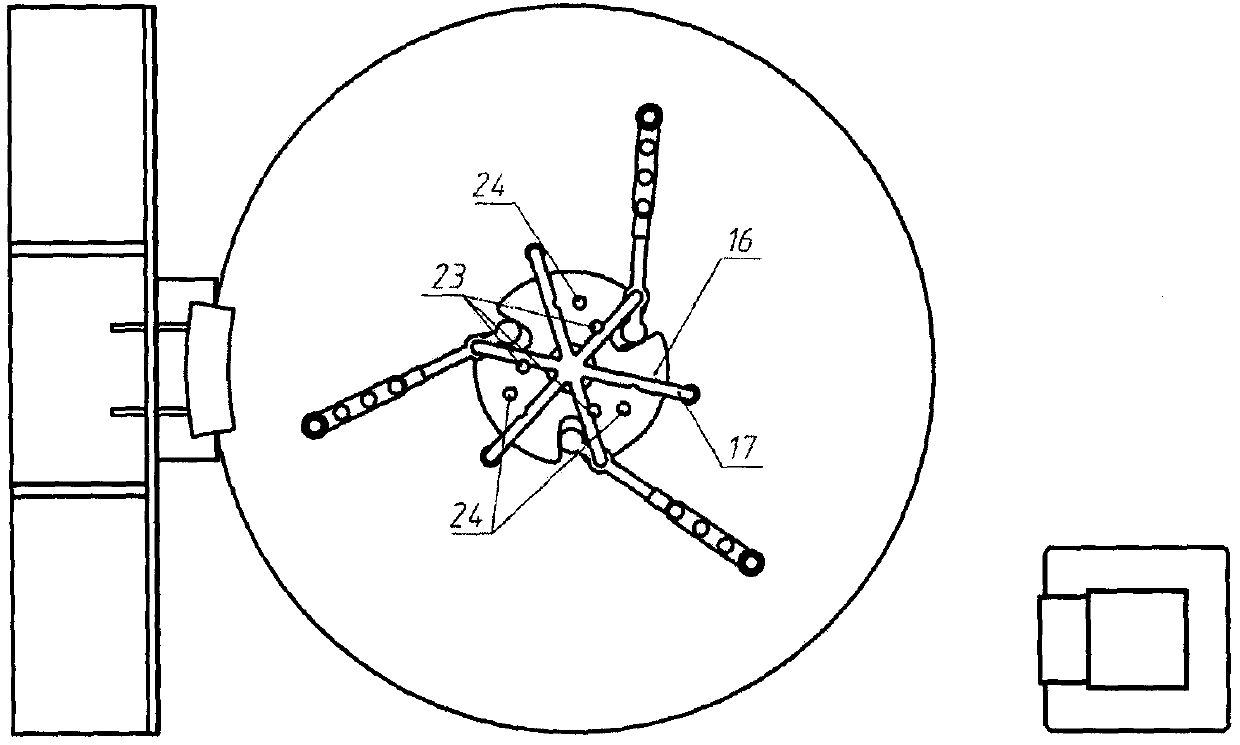

[0026] The present invention will be further described below with reference to the drawings and embodiments

[0027] Automobile wheel rim inspection platform, including background plate 1, hydraulic caliper 2, industrial camera 3, hub 4, horizontal axis 5, bevel gear I6, vertical axis 7, bevel gear II8, horizontal axis support frame 9, longitudinal axis support frame 10, End bearing I11, end bearing II12, end bearing III13, cylindrical pin 14, platform 15, synchronous groove wheel 16, synchronous frame 17, pendulum rod 18, compression spring 19, sleeve rod 20, extension rod 21, contact wheel 22, limit Pin I23 and limit pin II24 are characterized in that the horizontal axis 5 is installed on the horizontal axis support frame 9 with a bevel gear I6 at the front end; the vertical axis 7 is installed on the vertical axis support frame 10, and the bottom end is equipped with a cone Gear II8, bevel gear I6 mesh with bevel gear II8; the horizontal axis support frame 9 and the vertical a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com