Continuous oil-water separating and solvent reclaiming device for chemical synthesis or azeotropic rectification

A technology of azeotropic distillation and chemical synthesis, which is applied in the fields of chemical reaction engineering and separation engineering, can solve the problems of shortening the process time of chemical reaction, and achieve the effects of shortening process time, facilitating operation and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

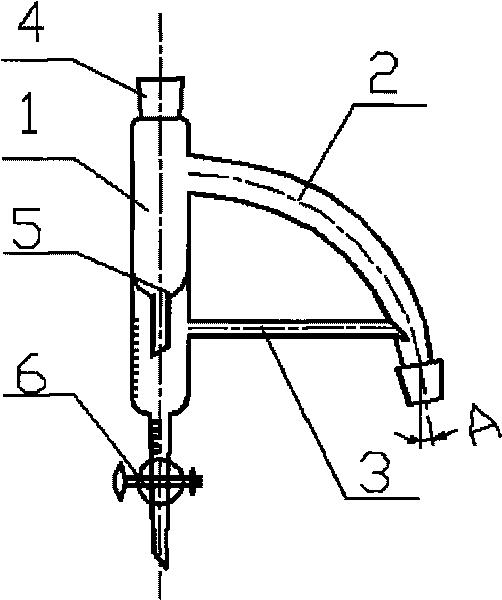

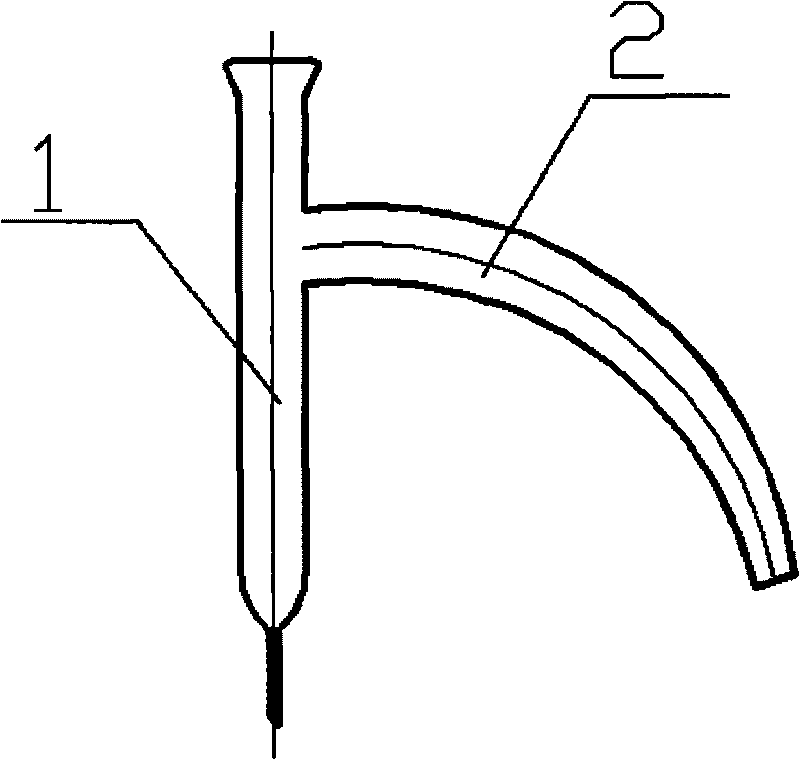

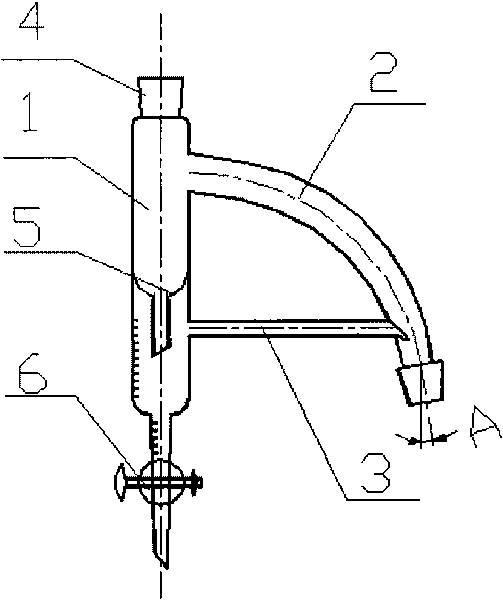

[0021] A continuous oil-water separation and recycling device for chemical synthesis or azeotropic distillation, such as figure 1 As shown, there is a collection chamber 1, an arc-shaped channel 2 communicating with the upper part of the collection chamber 1, characterized in that the bottom of the collection chamber 1 communicates with the bottom of the arc-shaped passage 2 through a horizontal overflow pipe 3, and the upper end of the collection chamber 1 is connected to the bottom of the arc-shaped passage 2. A condenser 4 with a suitable interface is connected.

[0022] In order to make the oil and water vapor condense into liquid through the condenser 4 and enter the lower part of the collection chamber 1 through the funnel-shaped passage 5 without the liquid level oscillating, a funnel-shaped passage 5 is provided in the middle of the collection chamber 1, and the funnel-shaped passage 5 The level of the outlet at the lower end is lower than the level of the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com