Derusting device for steel surface

A steel and derusting steel technology, which is applied in spraying devices, grinding/polishing safety devices, separation methods, etc., can solve the problems of poor derusting efficiency and derusting effect of workpieces, and achieve good derusting effect, easy collection, Excellent rust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

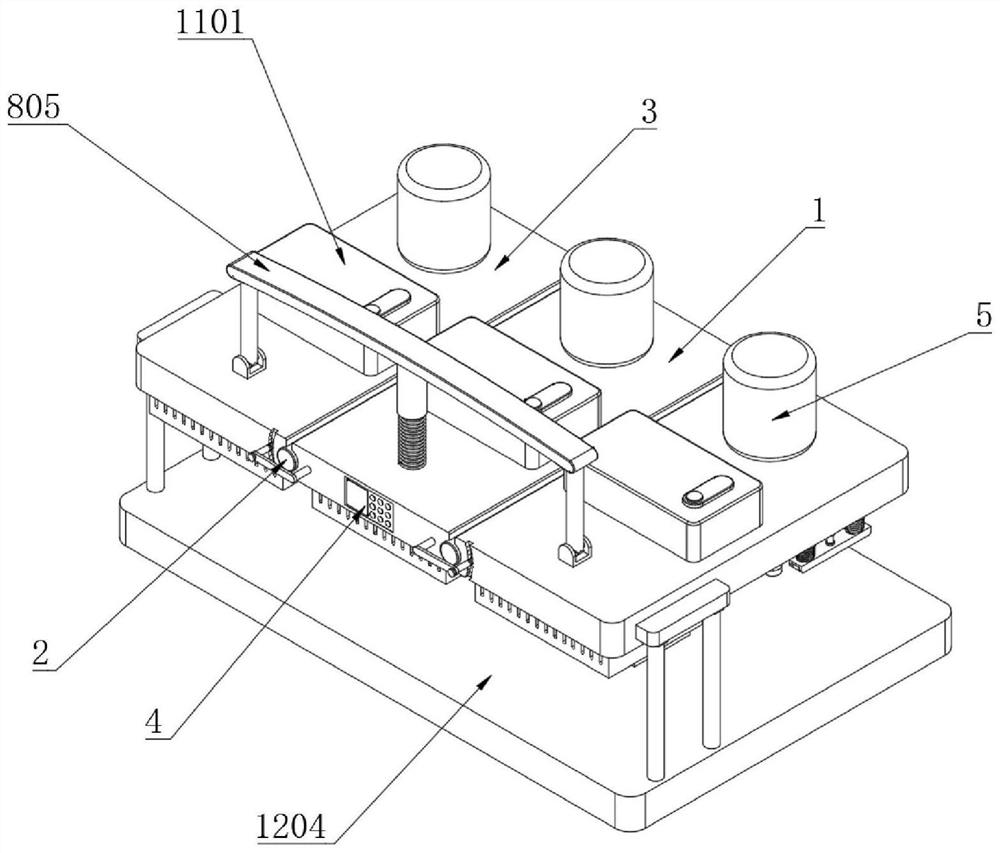

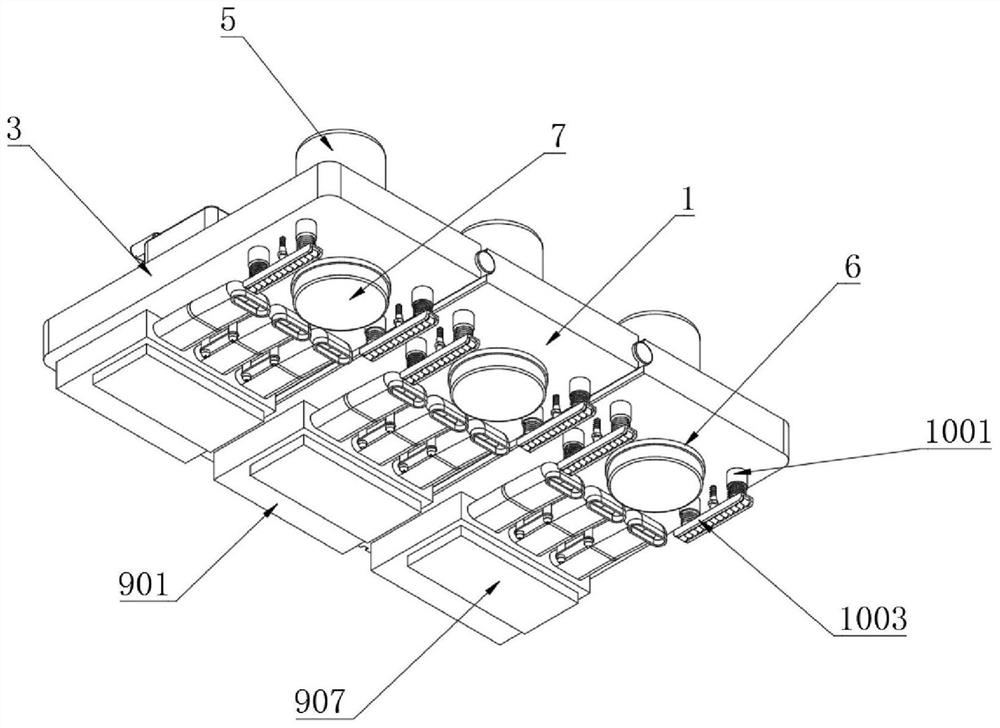

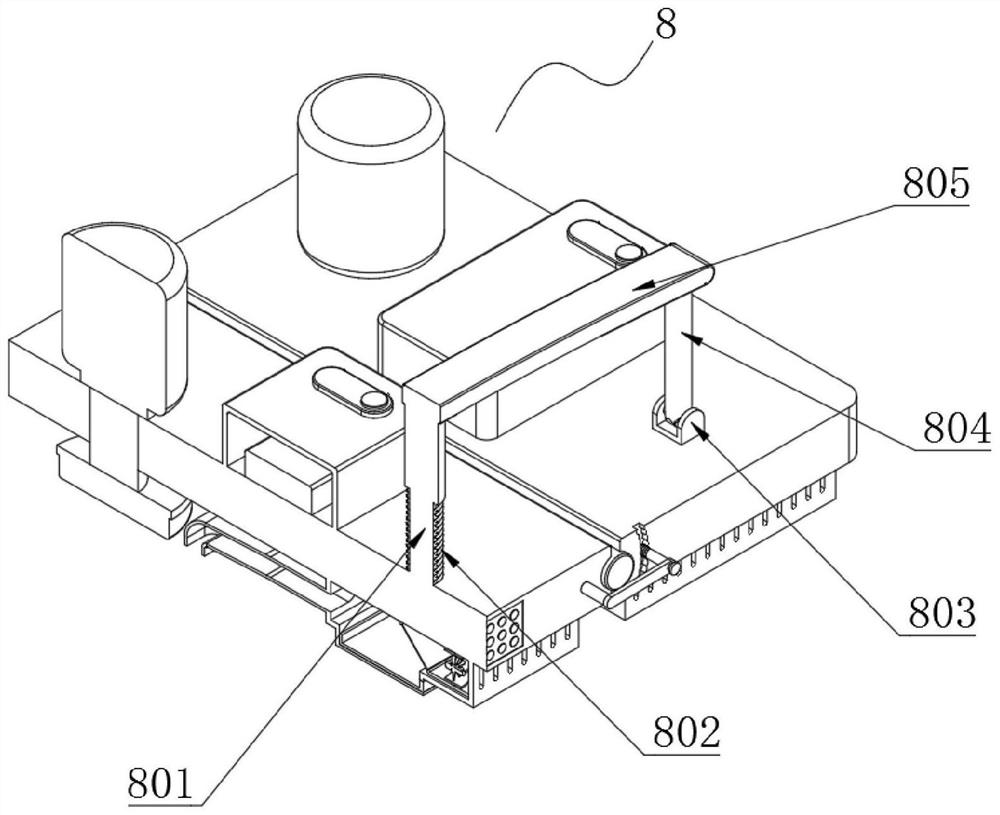

[0048] Example: such as Figure 1-9 As shown, the present invention provides a technical solution, a steel surface derusting device, including an installation middle plate 1, both ends of the installation middle plate 1 are rotatably installed with a rotating shaft 2, and the outer side of the rotating shaft 2 is fixedly connected with an installation side Board 3, one end of the installation middle board 1 is embedded with a control switch 4, the top of the installation middle board 1 and the installation side board 3 are fixedly connected with the drive motor 5, and the bottom end of the drive motor 5 passes through the installation middle board 1 and the installation side The plate 3 is installed with a rotating plate 6 through the rotation of the rotating shaft, and the bottom end of the rotating plate 6 is fixedly connected with a derusting wire brush 7;

[0049] Angle adjustment mechanism 8 is installed on the outside of installation middle plate 1 and installation side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com