Surface rust removal equipment for mechanical part machining

A technology for mechanical parts and equipment, which is applied in the field of surface rust removal equipment for mechanical parts processing, can solve the problems of incomplete rust removal, inability to grind and remove rust on the side of the plate, and rust, and achieve the effect of improving the effect of rust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

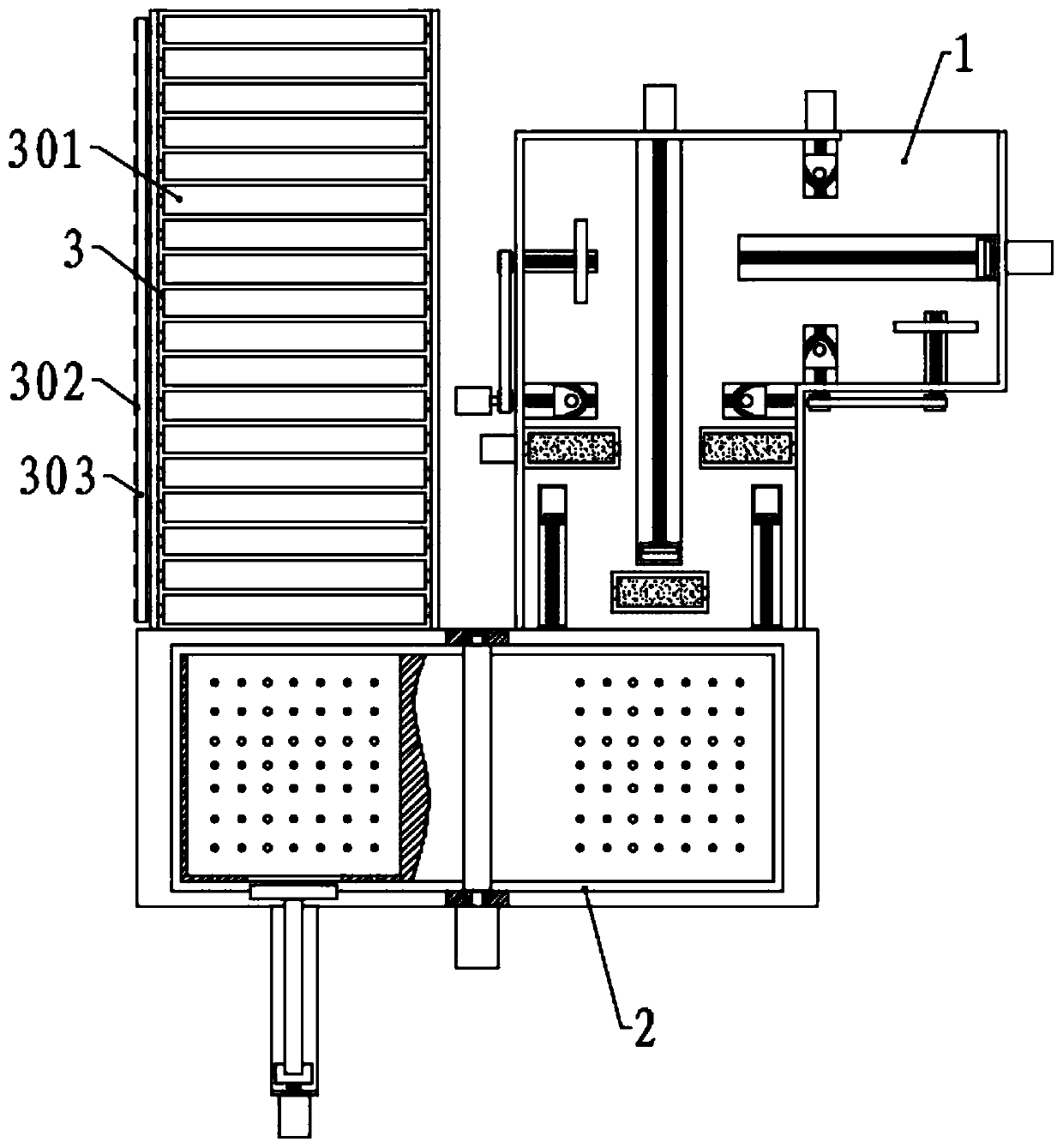

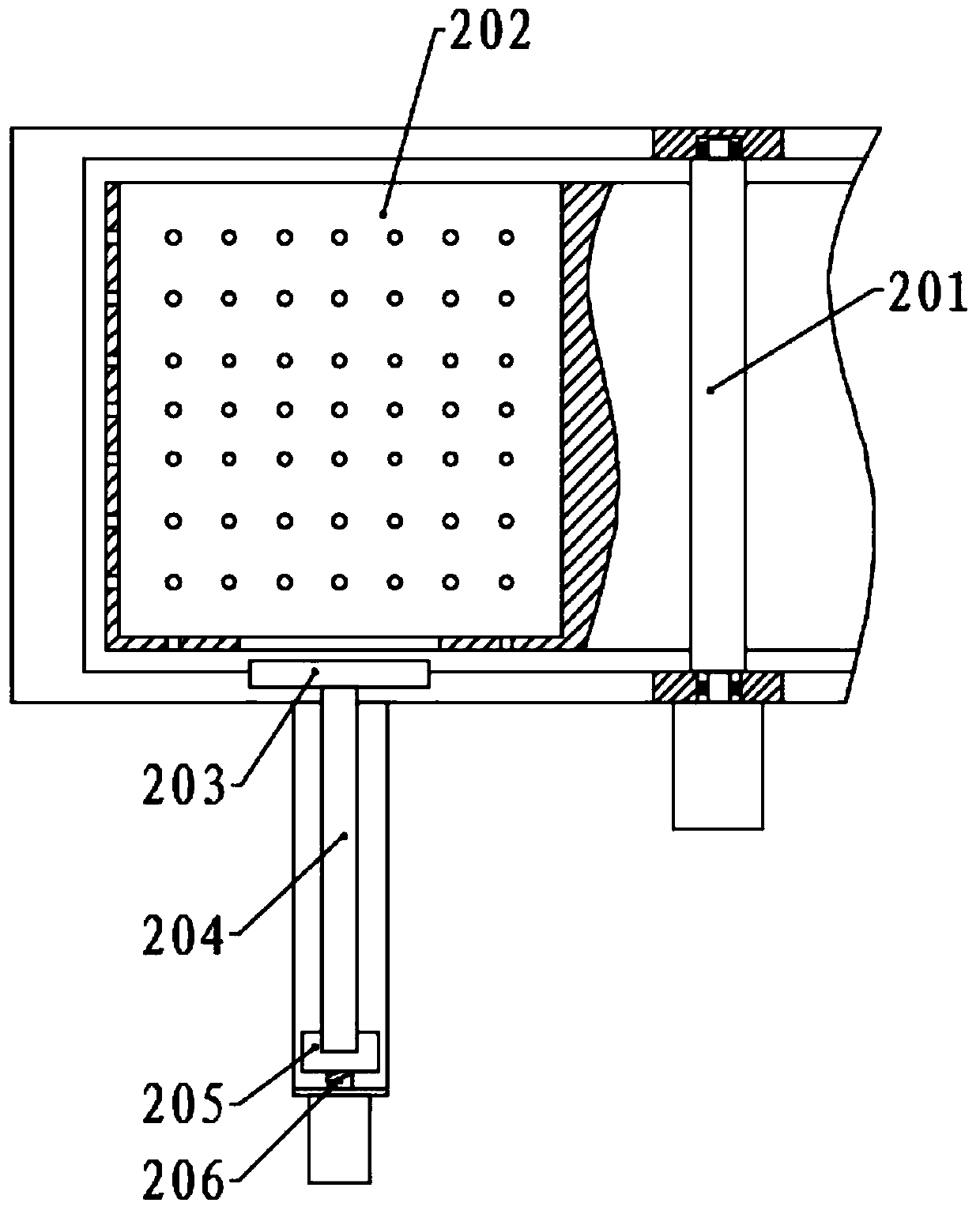

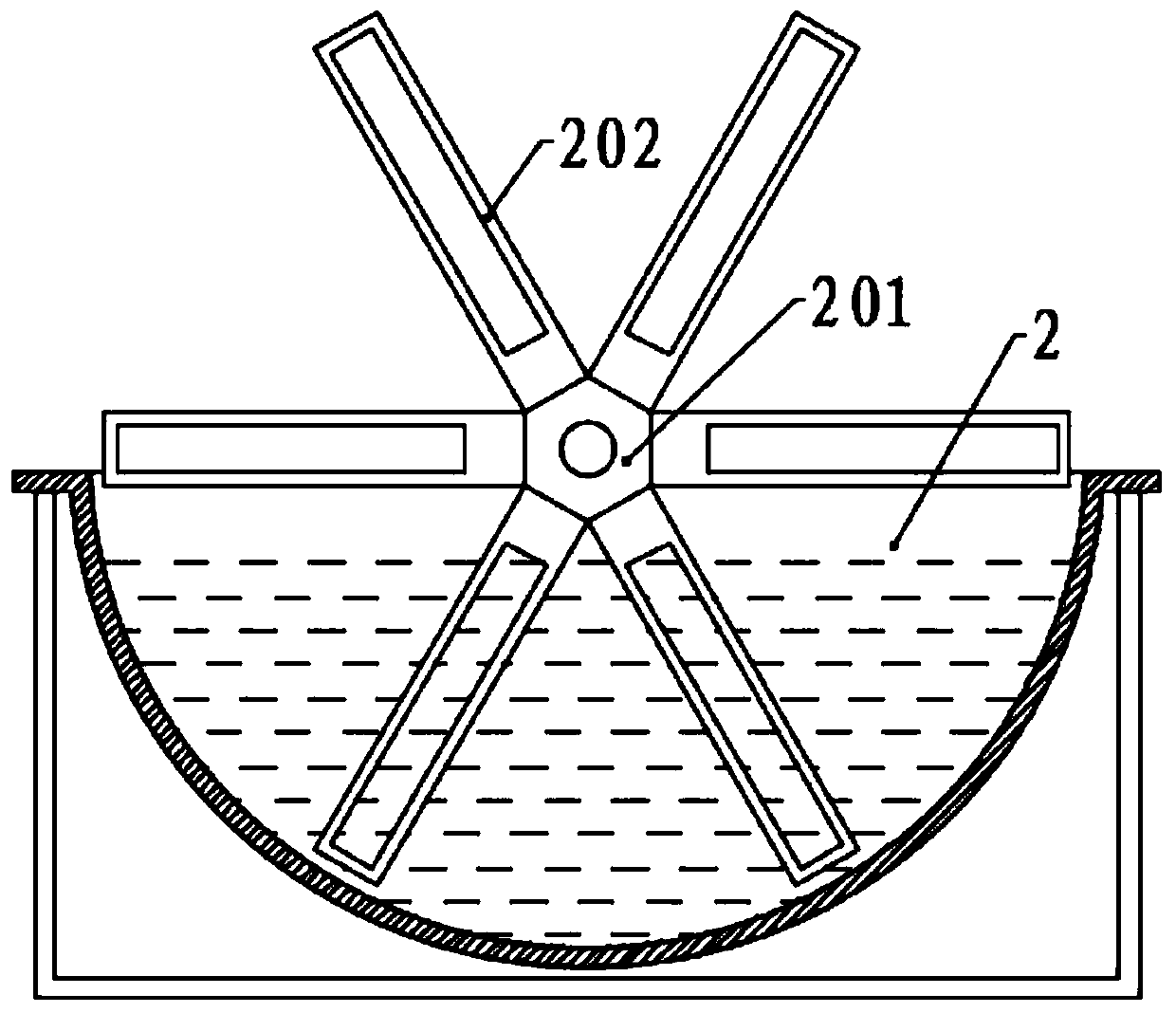

[0043] Please refer to the accompanying drawings, the present invention provides a technical solution: a surface derusting equipment for mechanical parts processing, comprising a soaking tank 2, the rear side of the soaking tank 2 is provided with a blanking mechanism and a feeding mechanism, and the soaking tank 2 is provided with There is a rotating mechanism, and the rotating mechanism includes a rotating column 201 that is rotatably connected to the middle of the soaking tank 2 tops. One end of the rotating column 201 is connected with a motor, and a plurality of rotating plates 202 are evenly fixed on the rotating column 201 along the circumferential direction. The rotating plates 202 There is a plate groove in the center, and a plurality of through holes are arranged on the side wall of the plate groove, the rear side end of the plate groove is set as an open shape, and a push port is provided in the middle of the other end, and the top of the soaking tank 2 corresponds to...

Embodiment 2

[0063] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that a limit plate 705 is provided on one side of the first side grinding assembly and the second side grinding assembly, and the limit plate 705 is connected to the top of the fixed table 1. The surface is slidingly connected, and the fixed table 1 is correspondingly provided with an adjusting groove, which is parallel to the corresponding moving groove, and the bottom surface of the limit plate 705 is fixed with an adjusting block, which is slidably connected in the adjusting groove, and is rotatably connected with an adjusting Screw rod, one end of the adjusting screw rod protrudes from the adjusting groove, and a pulley is fixed on the corresponding first screw rod 703, and the pulley is fixed on the corresponding first screw rod 703, and the two pulleys are connected by a transmission belt.

[0064] When the first screw rod 703 is rotated by the motor, the moving block ...

Embodiment 3

[0066] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that a ring gear 207 is jointly fixed between the outer ends of a plurality of rotating plates 202, and the bottom of the soaking tank 2 is evenly connected along the direction of the arc surface and is rotationally connected with a plurality of On the rotating shaft, a plurality of toggle plates 209 are evenly fixed along the circumferential direction, and a rotating gear 208 is fixed on one side of the rotating shaft, and the plurality of rotating gears 208 are all meshed with the ring gear 207 .

[0067] When the rotating mechanism drives the plates to rotate intermittently in the soaking tank 2, the ring gear 207 drives the rotating gear 208 to rotate, and the rotating gear 208 drives the rotating shaft and the toggle plate 209 to rotate, thereby generating agitation at the bottom of the soaking tank 2, making the soaking tank 2 The liquid is in full contact with the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com