Permanent magnet motor built-in mining explosion-proof lifting equipment

A permanent magnet motor, built-in technology, applied in the direction of electromechanical device, magnetic circuit shape/style/structure, magnetic circuit, etc., can solve the problems of low reliability, harsh use conditions, and unstable operation, so as to improve reliability. and the effect of running smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

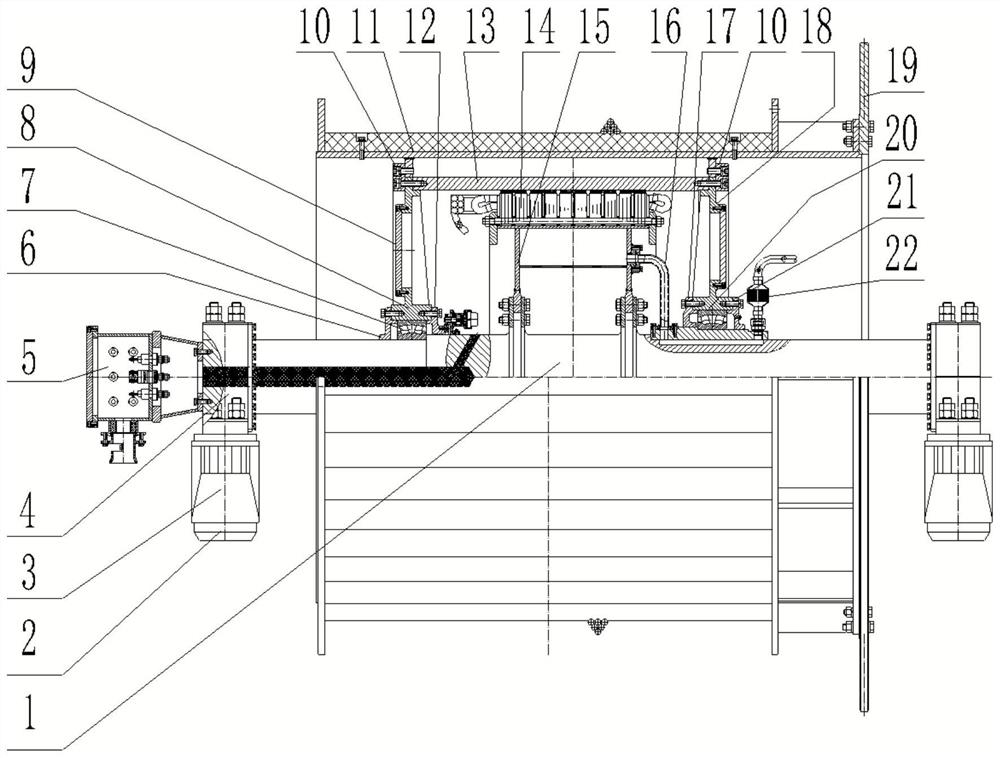

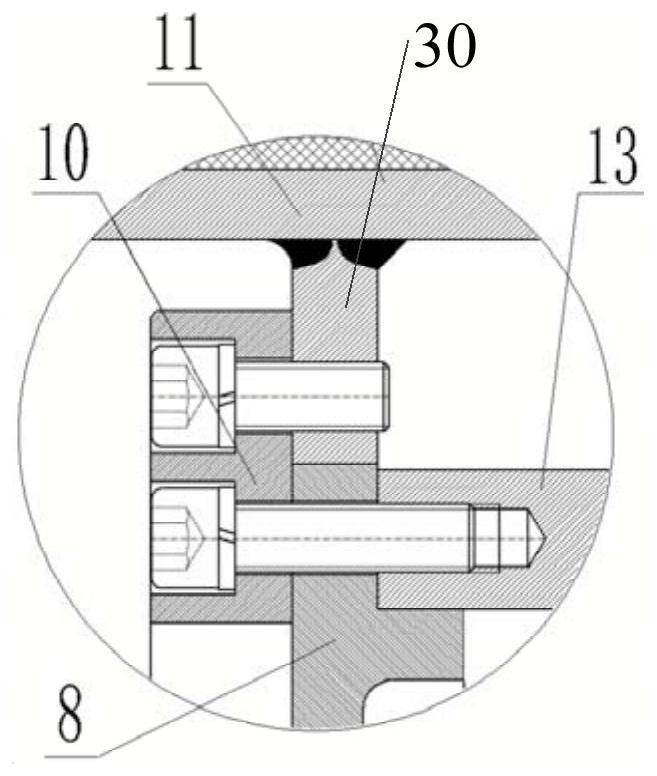

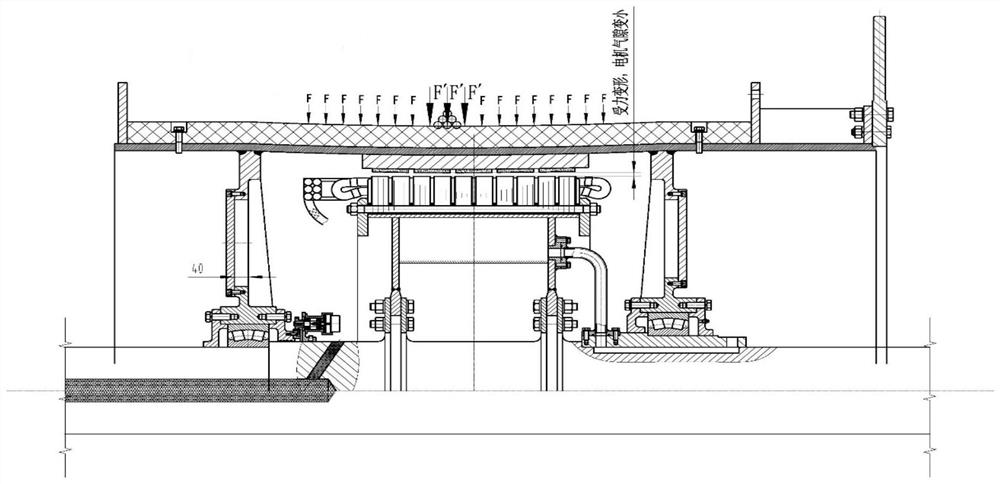

[0041] An embodiment of the present invention provides a mine flameproof lifting device with a built-in permanent magnet motor. The device includes:

[0042] A shaft fixed to the ground;

[0043] Permanent magnet motor stator fixed on the main shaft;

[0044] a reel rotating relative to the main shaft; the reel circumferentially surrounds the main shaft;

[0045] a permanent magnet motor outer rotor fixed by webs and rotating relative to said main shaft;

[0046] The reel is connected with the outer rotor of the permanent magnet motor through the isolation disc;

[0047] The radial distance between the outer circumferential surface of the outer rotor of the permanent magnet motor and the inner wall of the reel is greater than a preset value.

[0048] For brevity of description, the stator of the permanent magnet motor is referred to as the stator, and the outer rotor of the permanent magnet motor is referred to as the outer rotor.

[0049] Here, the main shaft is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com