A coating jig and coating method

A fixture and mounting position technology, applied in sputtering plating, vacuum evaporation plating, ion implantation plating, etc., can solve problems such as poor contact of electronic component pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions in the embodiments of the present application will be described below with reference to the accompanying drawings in the embodiments of the present application.

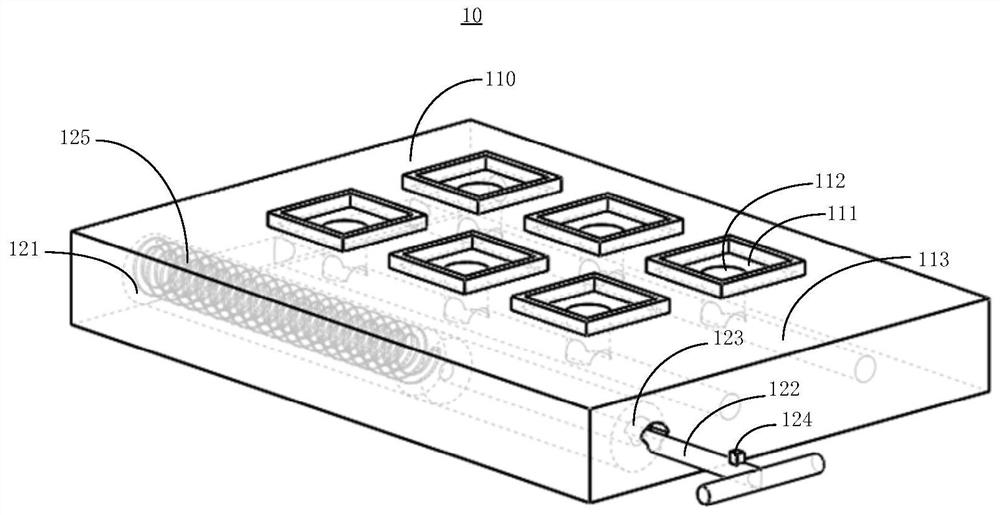

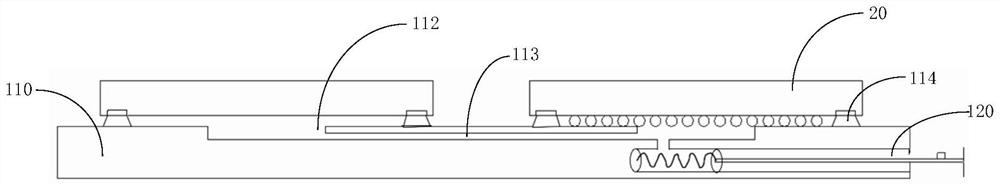

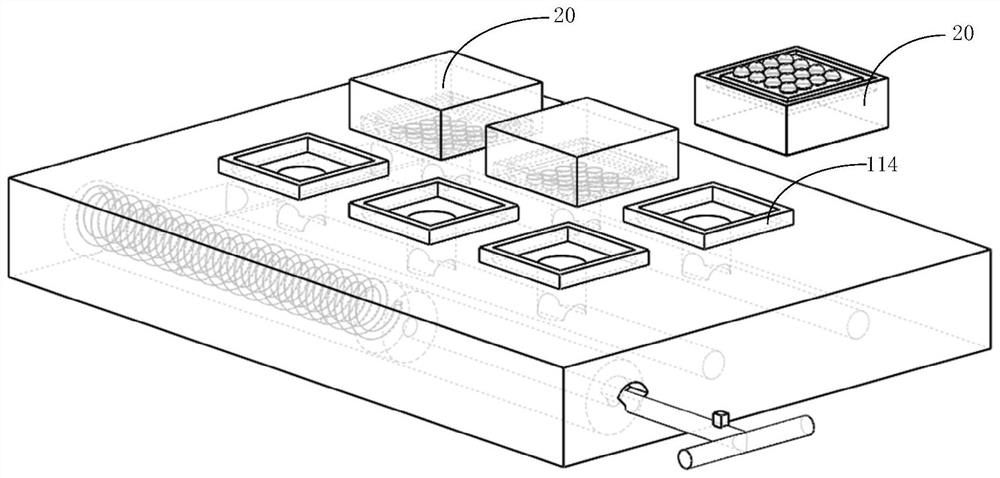

[0032] figure 1 A schematic diagram of a three-dimensional structure of a coating jig 10 provided in the embodiment of the present application, figure 2 A schematic cross-sectional structure diagram of a coating jig 10 provided in an embodiment of the present application, the coating jig 10 is used for placing the components 20 to be coated for coating, including: a jig body 110 and a pressure control device 120; The surface of the main body 110 is provided with at least one mounting position 111 , the mounting position 111 is used to place the components 20 to be coated, and the mounting position 111 is provided with a through hole 112 ; the fixture body 110 is provided with a ventilation channel inside 113, the first end of the ventilation channel 113 is communicated with the throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com