Rope head edge folding device

A technology of hemming device and rope head, applied in the field of garment production, can solve the problems of low work efficiency, difficult to ensure the uniformity of rope head forming, etc., and achieve the effect of better quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

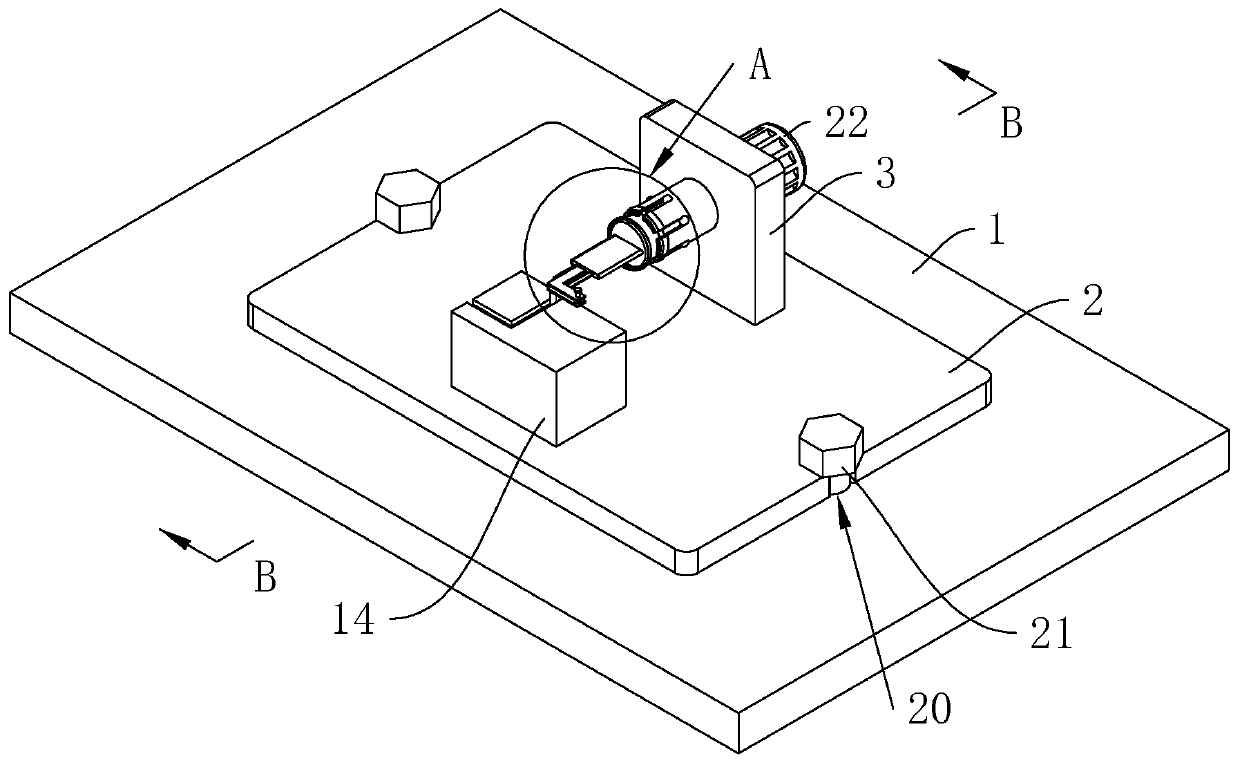

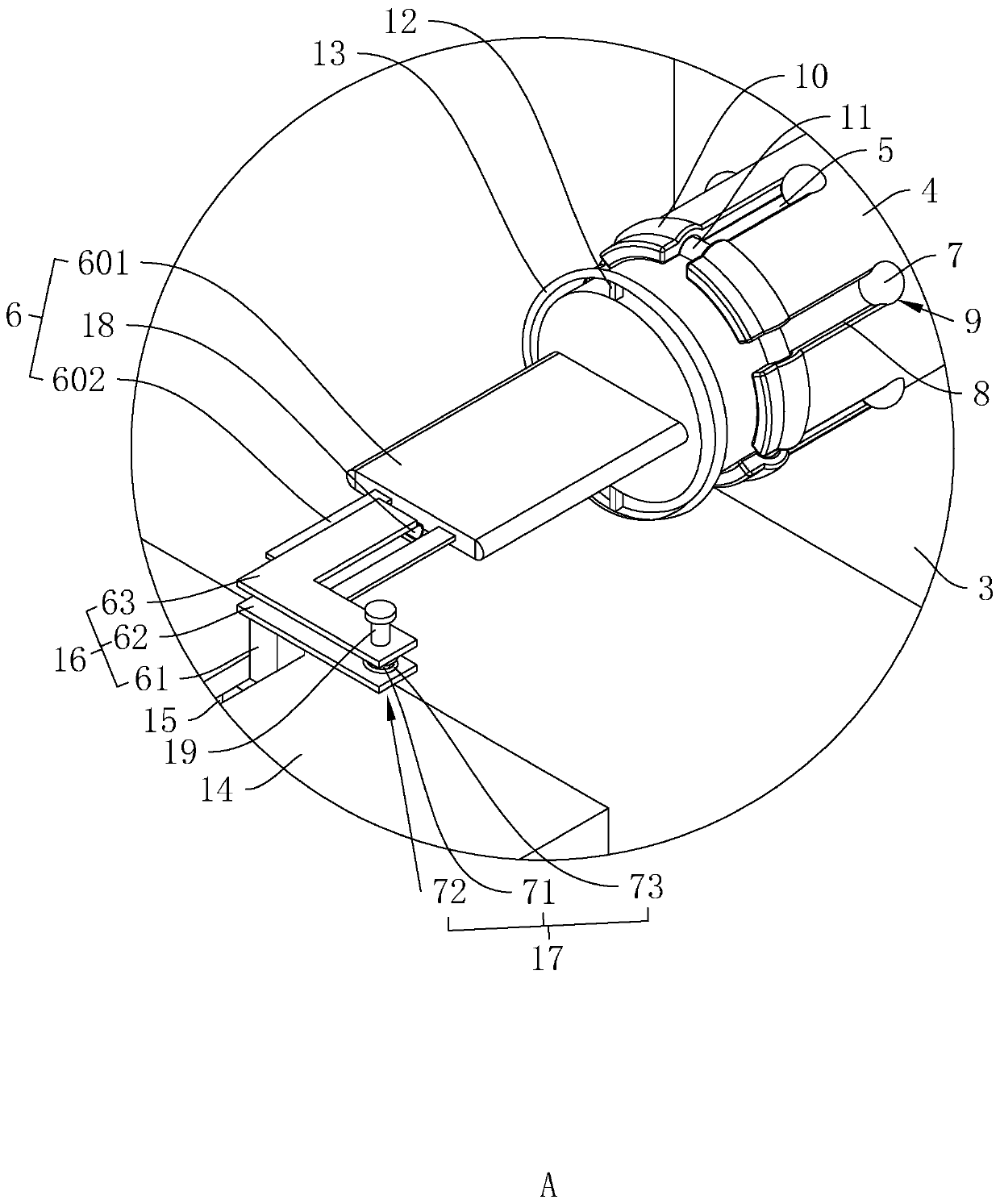

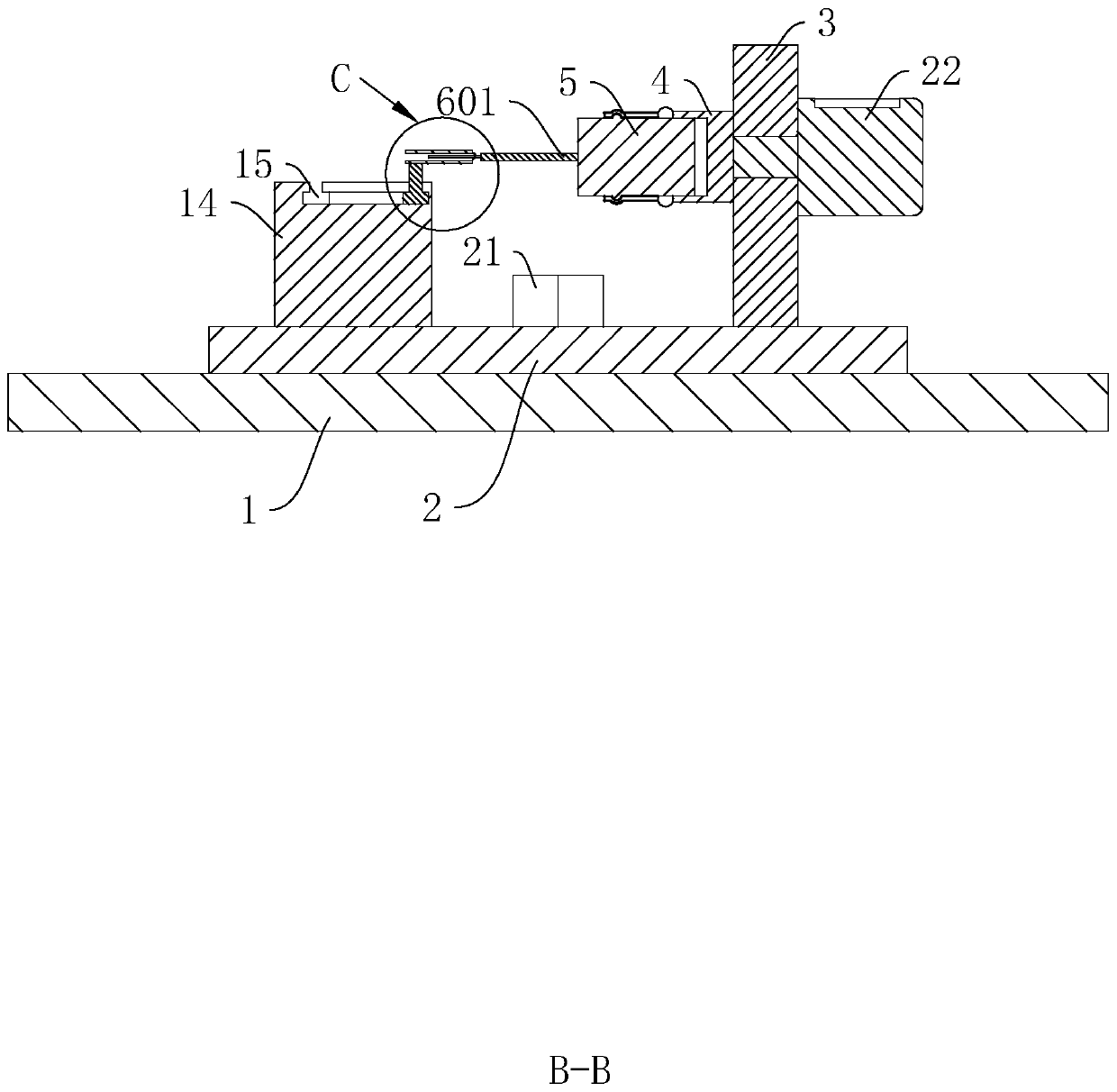

[0034] refer to figure 1 , is a rope end hemming device disclosed in the present invention, comprising a workbench 1, a bottom plate 2 is detachably installed on the upper end surface of the workbench 1, and waist-shaped grooves are opened inward on two corresponding surfaces on both sides of the bottom plate 2 20. The waist-shaped groove 20 is installed with a screw 21 threadedly connected to the workbench 1, and the head of the screw 21 is pressed against the upper end surface of the bottom plate 2. The operator can screw the screw 21 into or out of the waist-shaped groove. Groove 20, just whole body can be pulled down from workbench 1, so that maintenance. The top of the bottom plate 2 is vertically fixed with a rectangular riser 3, one side of the riser 3 is horizontally connected to a sleeve 4, the end of the sleeve 4 away from the riser 3 is open, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com