Large-span suspension bridge GFRP rib prefabricated slab composite beam bridge deck system and construction method thereof

A technology of prefabricated bridges and bridge deck systems, which is applied in the direction of suspension bridges, bridges, bridge parts, etc., to achieve the effects of good economy, reduced cracks, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0031] The invention proposes a GFRP tendon prefabricated slab composite girder deck system for a long-span suspension bridge.

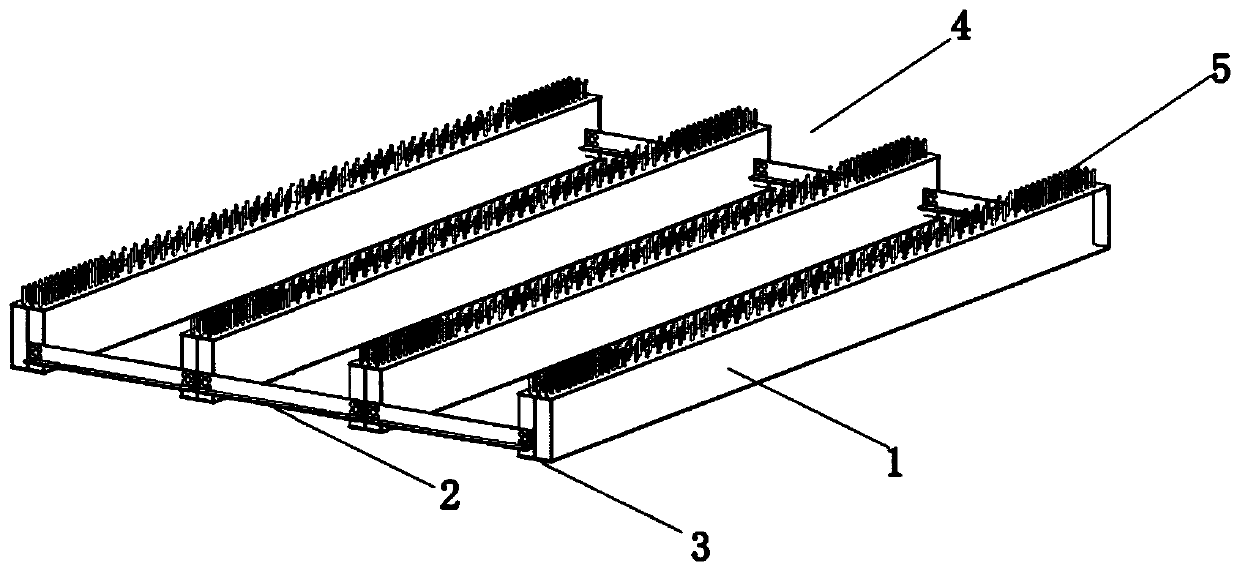

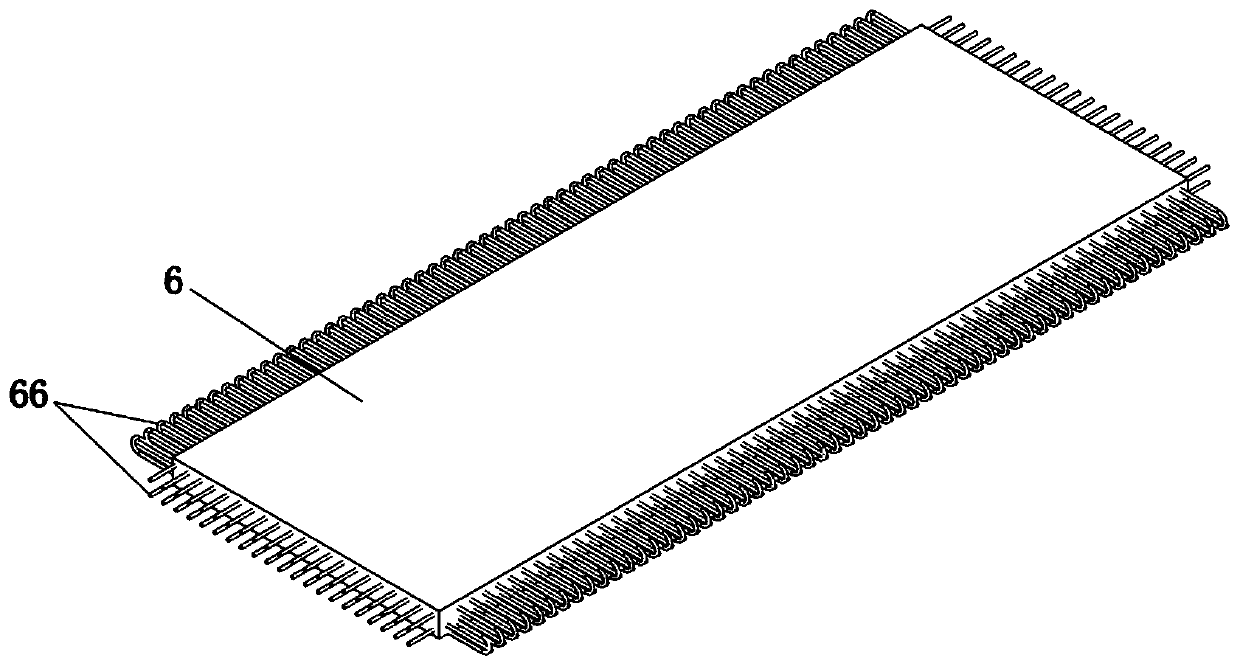

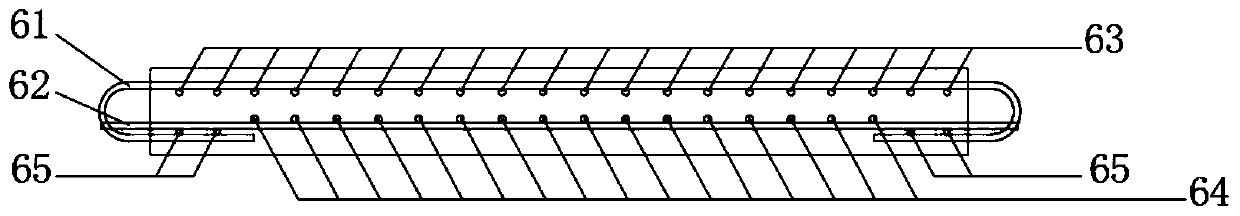

[0032] refer to Figure 1 to Figure 6 , in this preferred embodiment, a long-span suspension bridge GFRP reinforced prefabricated slab composite girder deck system, including steel longitudinal girder 1, transverse tie girder 2, prefabricated bridge deck 6 and cast-in-place concrete joint 7, wherein,

[0033] Multiple (multiple refers to two or more) steel longitudinal beams 1 are arranged in parallel and at intervals, the two ends of the multiple steel longitudinal beams 1 are fixedly connected by two transverse tie beams 2, and the top of the steel longitudinal beams 1 is arranged with bolts The shear key 5 is nailed, the prefabricated bridge deck 6 is erected above two adjacent steel lon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com