Kitchen waste processor capable of effectively treating plant fibers and working method thereof

A technology of plant fiber and kitchen waste, applied in the field of kitchen utensils, which can solve the problems of short service life and easy wear of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described below in conjunction with accompanying drawing and specific embodiment:

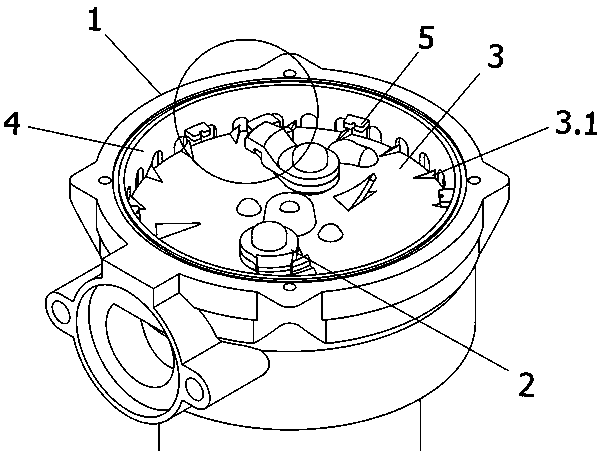

[0038] Such as Figure 1~6 As shown, a kitchen waste disposer capable of effectively processing plant fibers includes a body shell 1, and the body shell 1 is a hollow cylinder;

[0039] The inner side wall of the body shell 1 is provided with a filter tray 4, and the lower end of the filter tray 4 has uniform openings around it;

[0040] A grinding disc 3 is installed in the body shell 1, and the gap between the openings of the grinding disc 3 and the water filter disc 4 forms a water filter cavity;

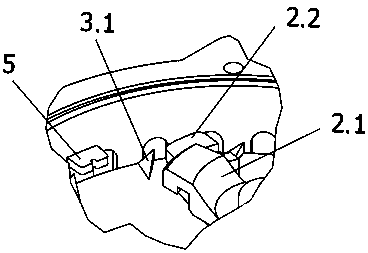

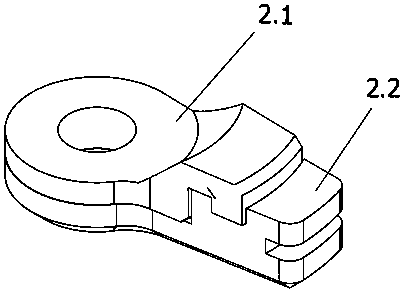

[0041] The grinding disc 3 is symmetrically provided with a plurality of impact blocks 2, the impact block 2 includes an upper pendulum 2.1 and a lower pendulum 2.2, and the upper pendulum 2.1 and the lower pendulum 2.2 swing coaxially;

[0042] A plurality of cutting bevels 3.1 are additionally provided on the grinding disc 3, and the cutting bevels 3.1 are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com