Wet cooling unit low-pressure cylinder zero-power heat supply system and work method

A heating system, low-pressure cylinder technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve problems such as high pipeline pressure, freezing damage to cooling towers, pipeline damage, etc., to increase heat load, reduce energy consumption, The effect of zero cold source loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

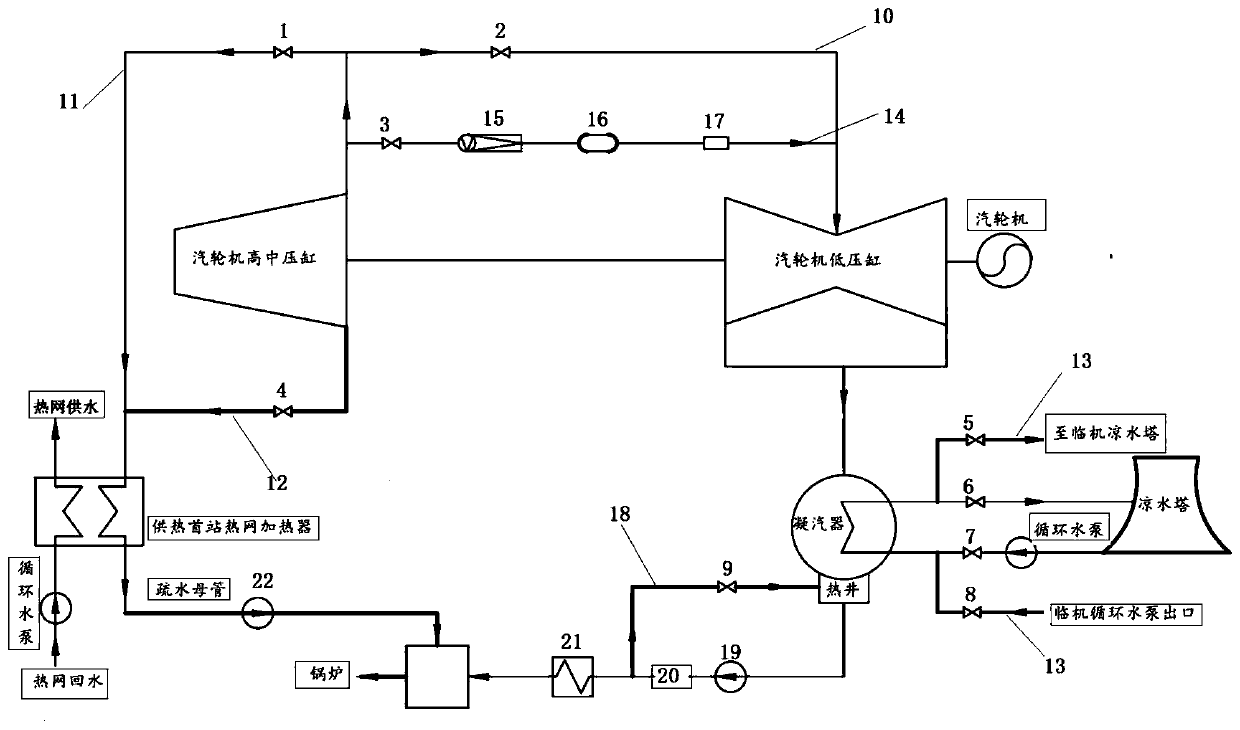

[0025] In the technical solutions disclosed in one or more embodiments, such as figure 1 As shown, a low-pressure cylinder zero-power heating system of a wet-cooling unit includes a steam turbine high-medium pressure cylinder, a steam turbine low-pressure cylinder, and a medium-low pressure communication pipe 10 connecting the steam turbine low-pressure cylinder intake end and the steam turbine high-medium pressure cylinder exhaust end, and the steam turbine low-pressure cylinder The steam exhaust end is connected to the cooling tower of this unit through the condenser, the sixth valve group 6, and the seventh valve group 7; a cooling bypass pipeline 13 can also be set, and the condenser is connected to the cooling tower through the cooling bypass pipeline 13 The cooling tower of another unit.

[0026] In this embodiment, cooling bypass pipes are arranged at the output end of the condenser to connect the cooling towers of other units except this unit, so that when the low-pres...

Embodiment 2

[0044] This embodiment provides a working method of the low-pressure cylinder zero-power heating system of the wet-cooling unit described in Embodiment 1, including the operation control method of the back pressure heating mode, the control method of the condensate heating operation mode and the control method of the pure condensate operation mode The method, the operation control method of the back pressure heating mode, includes the following steps:

[0045] Step 11, open the first valve group 1, the fourth valve group 4 and the drain pump 22;

[0046] Step 12, open the third valve group 3 of the desuperheating steam pipeline 14, the desuperheating and pressure reducing device 15, the steam-water separator 16 and the measuring module 17;

[0047] Step 13. Obtain the steam parameter data detected by the desuperheating steam pipeline 14. When the detected steam parameter data meets the steam conditions for zero-power operation of the low-pressure cylinder, switch the operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com