Hinged Array Ultrasonic Phased Array Transducer Probe Control Method

An ultrasonic phased array and control method technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. , to reduce the detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

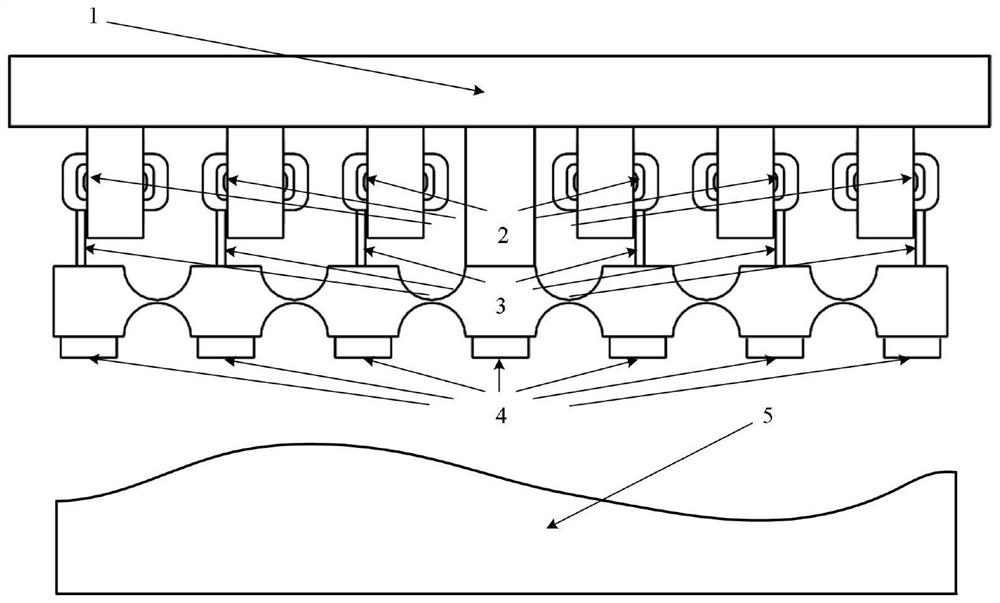

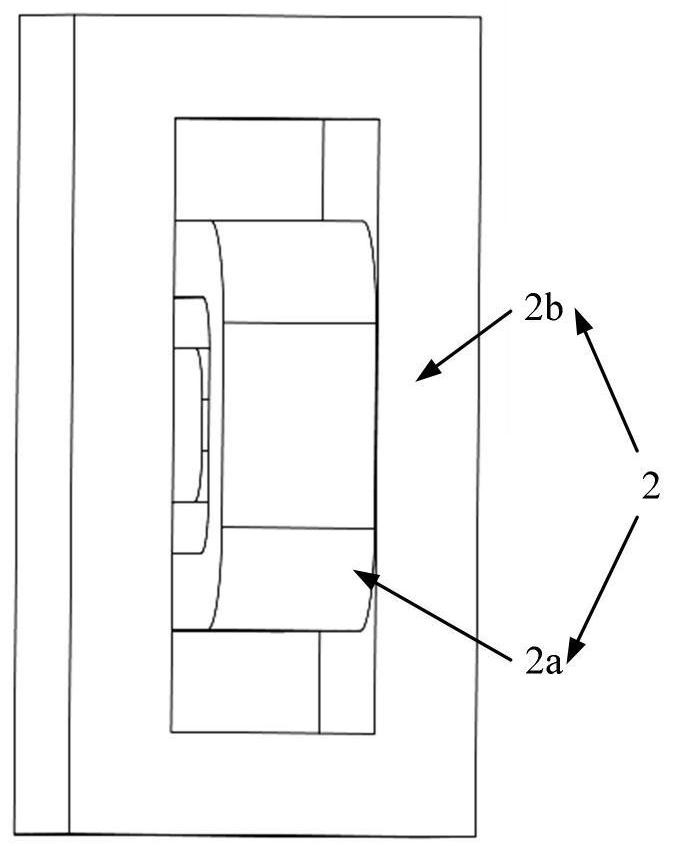

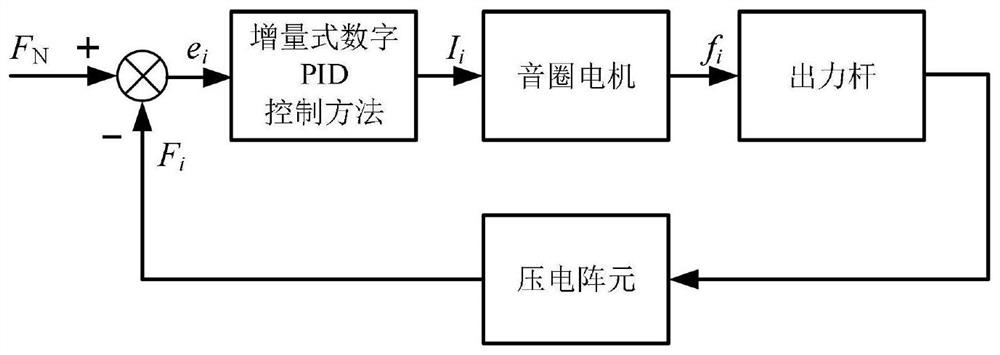

[0017] A hinge array ultrasonic phased array transducer probe control method, the method is: firstly fix the test piece 5, make the central piezoelectric array element of the piezoelectric array element 4 contact with the surface of the test piece 5, and then Fix the fixed bracket 1; the magnetic cylinder 2b of the voice coil motor is symmetrically arranged and fixedly connected to the fixed bracket 1; before starting the test, use the voice coil motor 2 to drive the hinge array so that the piezoelectric array element 4 is completely attached to the surface of the DUT 5 The number of piezoelectric array elements is 2N+1 (N=1, 2, 3, 4, 5), and different N values are selected according to the size of the test piece; the piezoelectric array element 4 As a pressure sensor, collect each pressure value, F 1 , F 2 ,...,F N ,...,F 2N , F 2N+1 ; Take the pressure value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com