Method of making self-standing electrodes supported by carbon nanostructured filaments

A self-supporting, carbon nanotube technology, applied in the direction of carbon nanotubes, nanocarbons, battery electrodes, etc., can solve the problems of expensive, inevitable reduction and defects, and degradation of nanotube performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

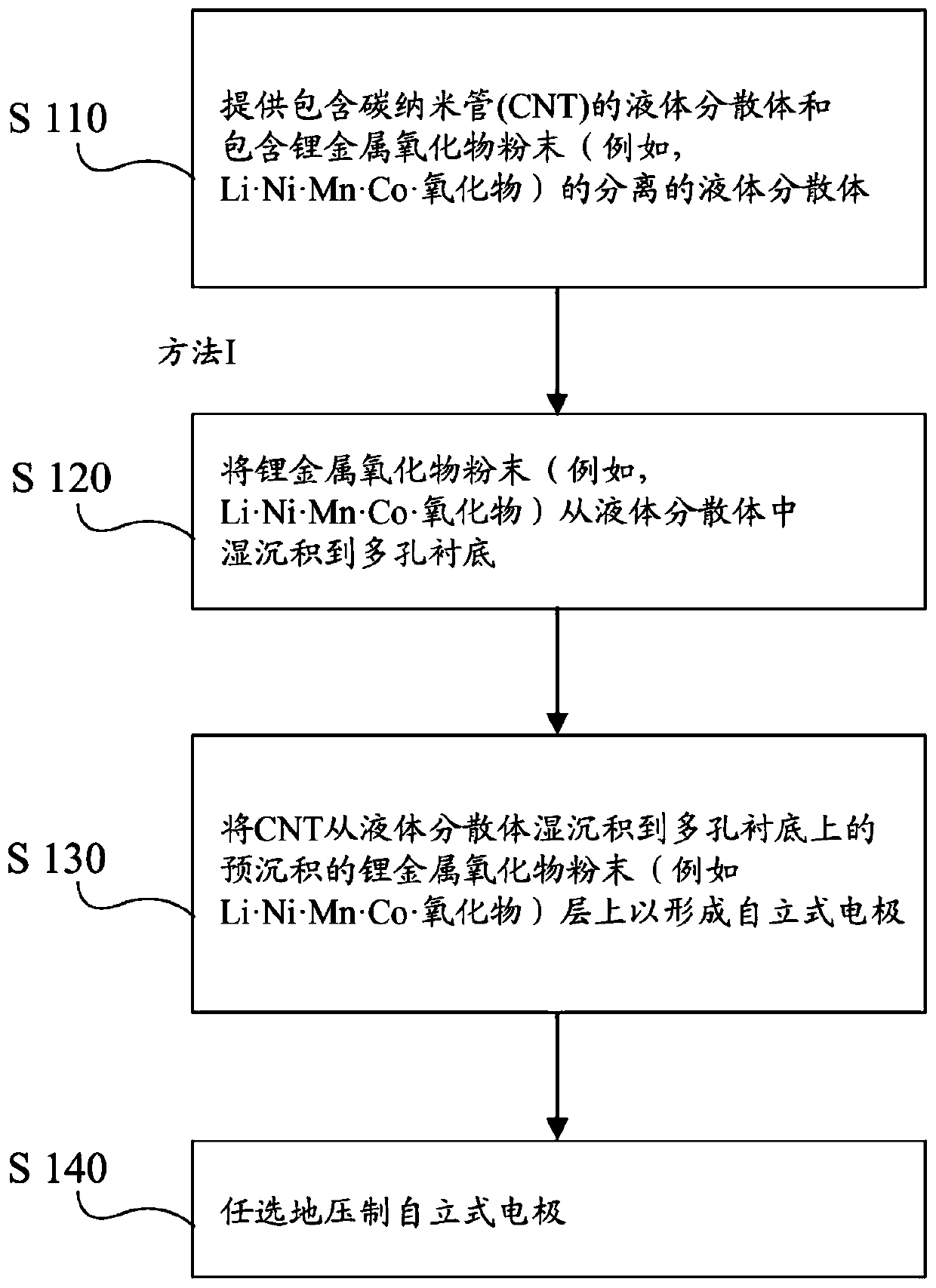

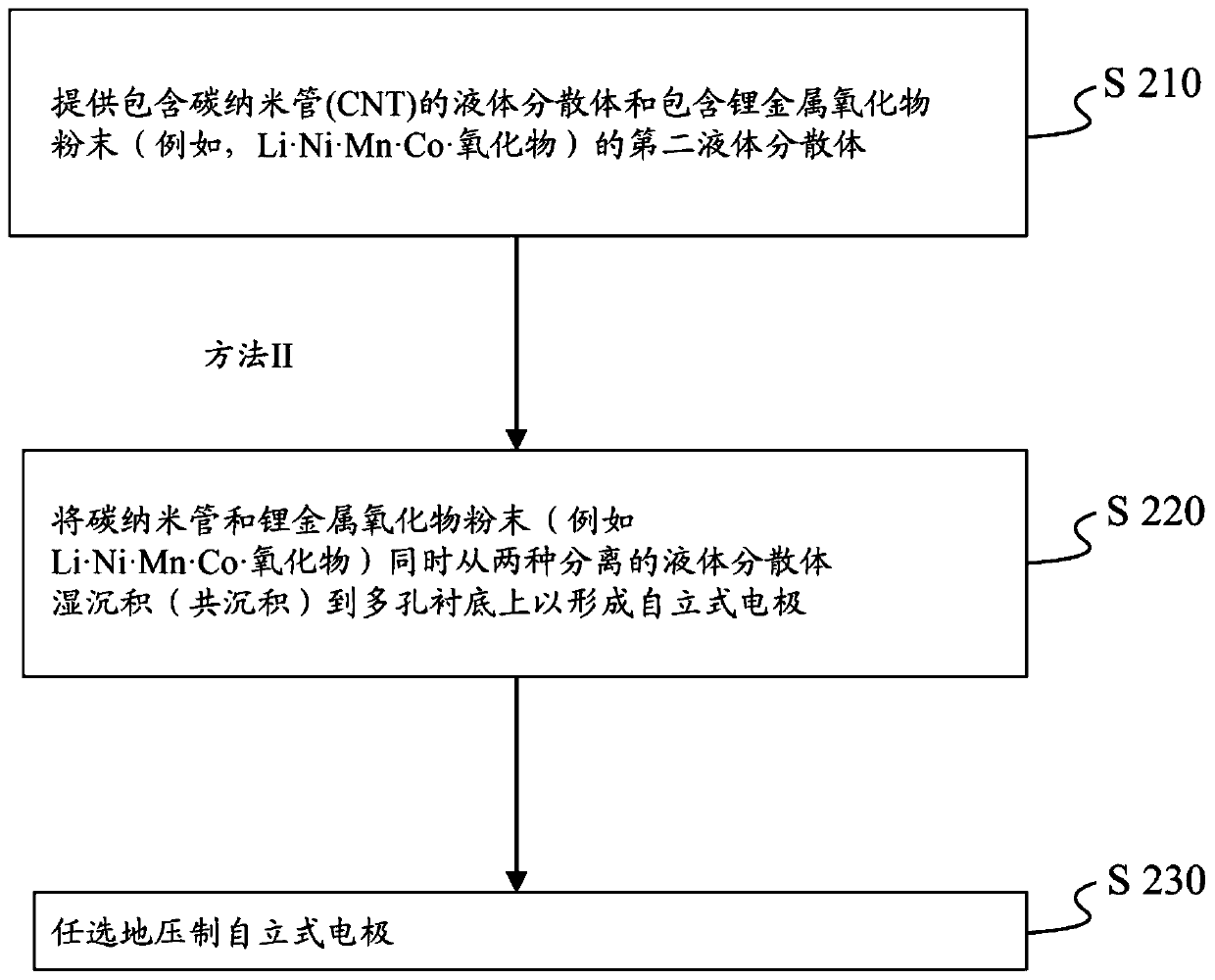

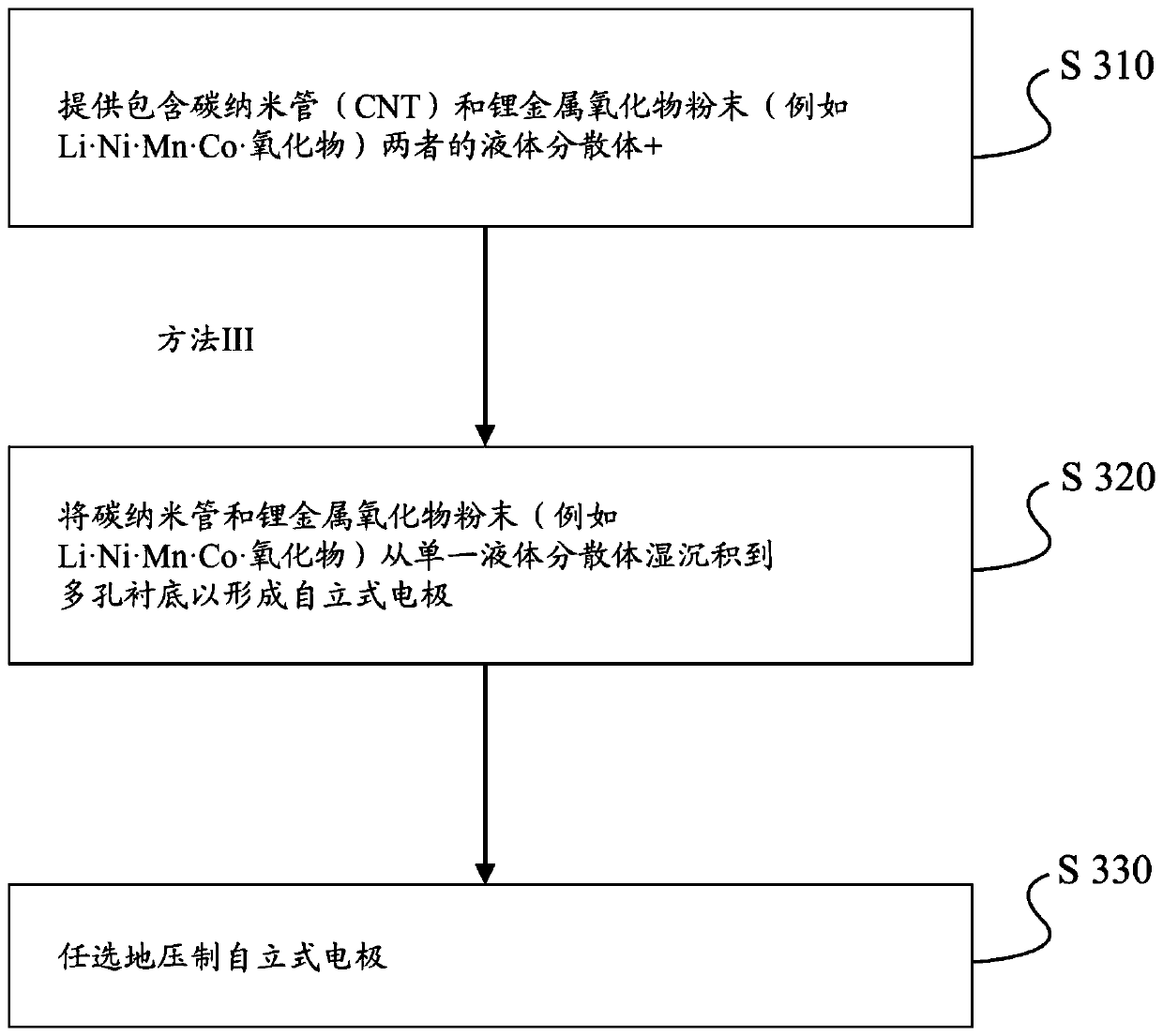

[0015] The present disclosure provides methods for making free-standing electrodes. Also provided are free-standing electrodes comprising a mixture of nanotubes and electrode active materials. In one embodiment, a free-standing electrode is prepared by first providing a liquid dispersion comprising carbon nanotubes (or carbon fibers) and a separate liquid dispersion comprising an electrode active material, and wet depositing the electrode active material onto a mobile porous substrate, and then wet-deposit carbon nanotubes or carbon fibers onto the electrode active material layer on the porous substrate. The resulting composites of electrode active materials and carbon nanotubes, such as single-wall nanotubes and multi-wall nanotubes, can be removed or exfoliated from the porous substrate to form free-standing electrodes. The substrate can be made of any type of filter material or mixtures thereof. Examples of backing materials include cellulose, cloth, and any type of mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com