Fast-assembly and fast-disassembly type intelligent outgoing line cabinet bus cover

An outlet cabinet and quick-dismantling technology, which is applied in the field of quick-installation and quick-dismantling smart outlet cabinet busbar cover, can solve the problems of wasting manpower, many fasteners, and small space in the outlet cabinet, so as to reduce manpower waste, reduce the number of bolts, The effect of workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

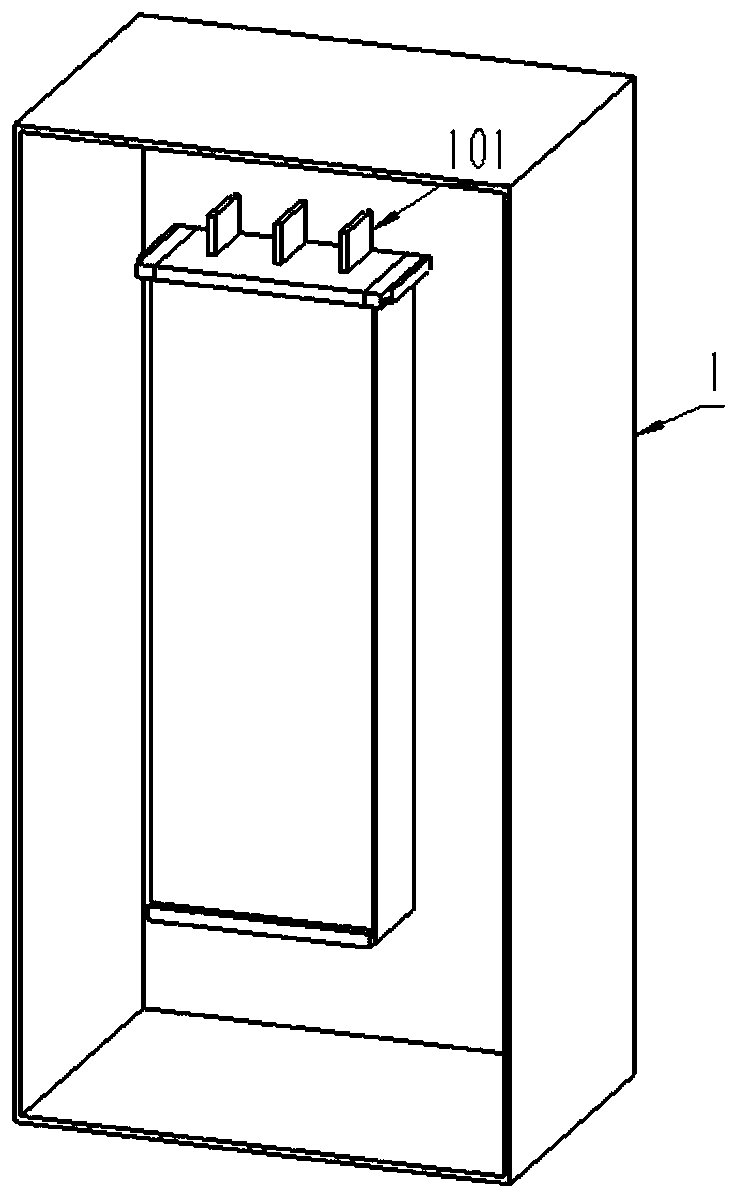

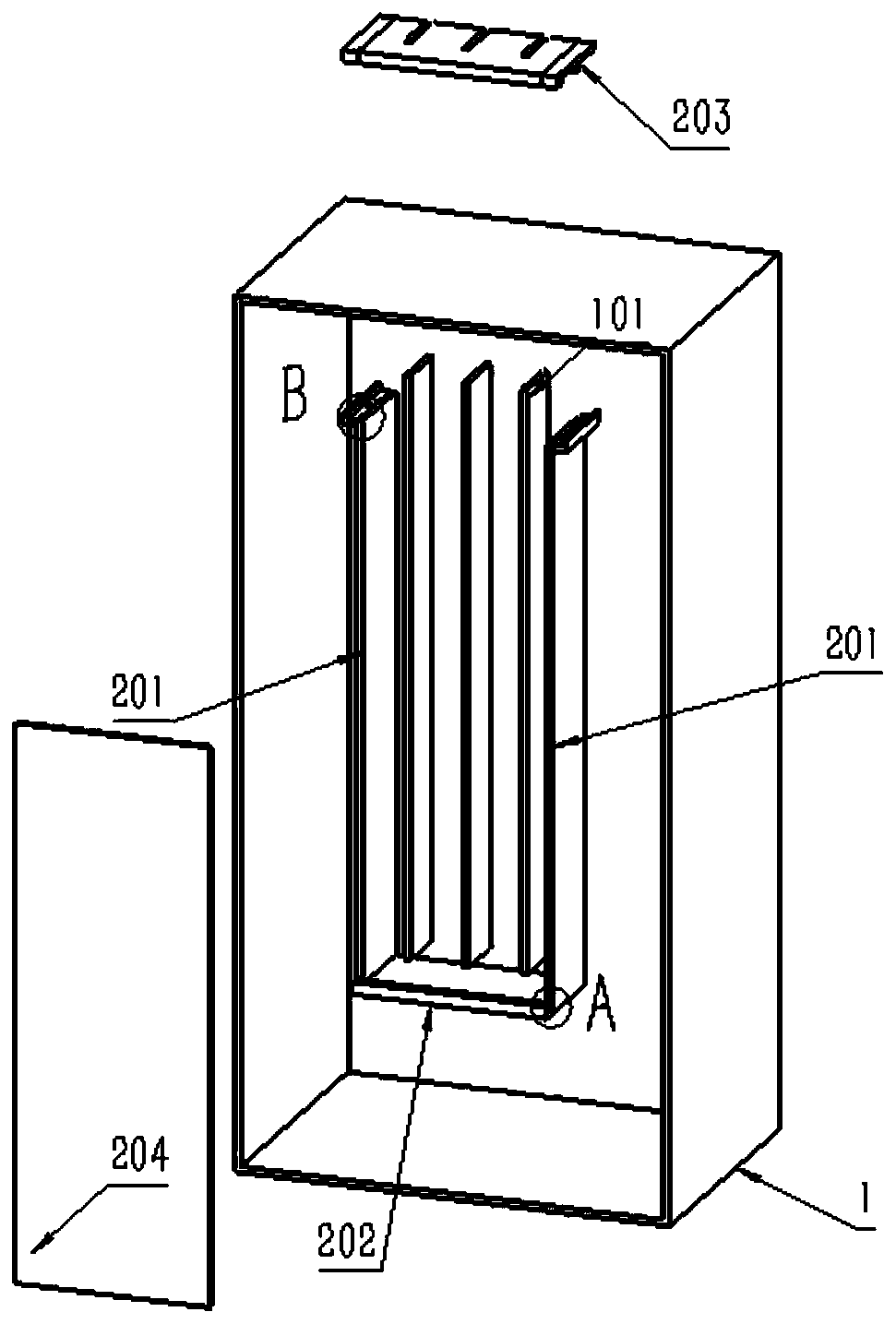

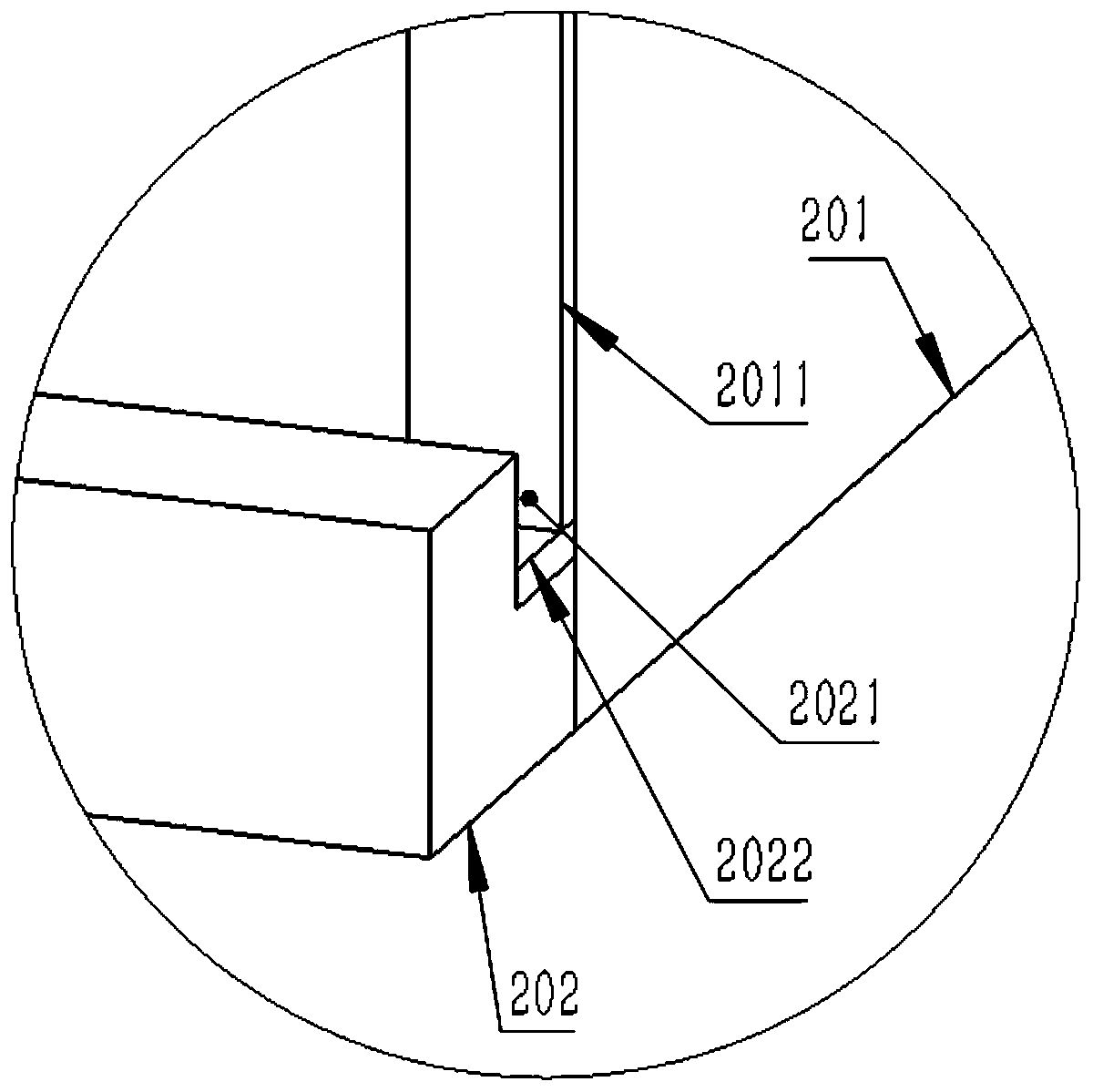

[0038] Example 1: Reference Figure 1 to Figure 5 , a busbar cover of a quick-installation and quick-disassembly intelligent outlet cabinet, including: side panels 201, the side panels 201 comprising two pieces, the side panels 201 are fixedly connected to the left and right sides of the busbars in the outlet cabinet 1; the lower baffles 202, The lower baffle plate 202 is fixedly connected to the lower end of the side plate 201 in the outlet cabinet 1, the upper surface of the lower baffle plate 202 protrudes from the front surface of the side plate 201, and the part of the upper surface of the lower baffle plate 202 protruding from the front surface of the side plate 201 is provided with a card slot 2021, the length direction of the slot 2021 is the left and right direction; the upper baffle 203, the left and right sides of the upper baffle 203 are detachably connected to the upper ends of the two side plates 201 respectively, and the front part of the lower surface of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com