Temporary connection structure between truss type steel pipe framework sections and arch bridge

A steel tube skeleton and temporary connection technology, applied in arch bridges, erecting/assembling bridges, bridges, etc., can solve problems such as increasing operating procedures, affecting construction period, quality defects, etc., reducing the number of bolts, reducing engineering costs, and large safety margins Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

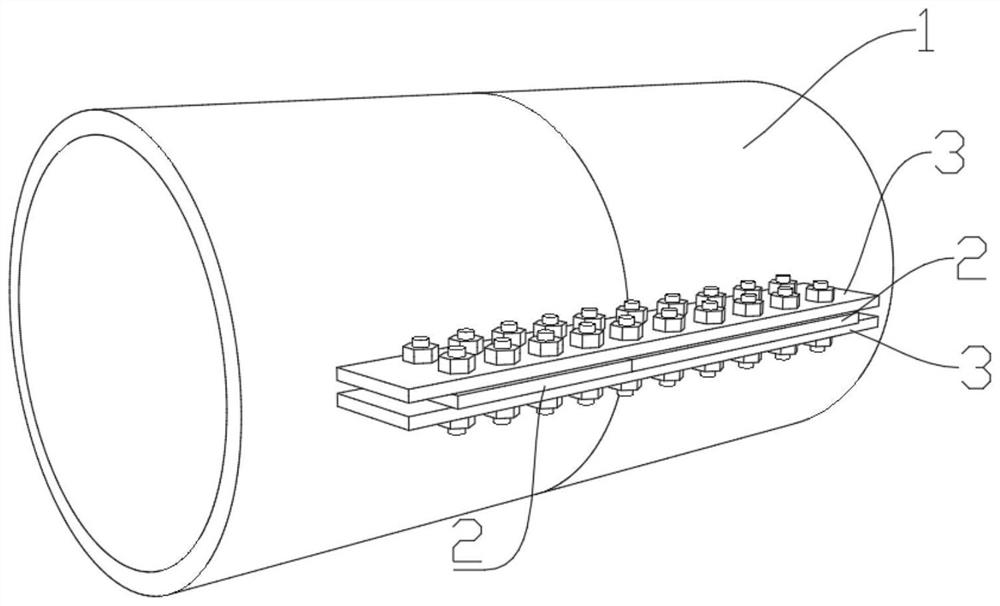

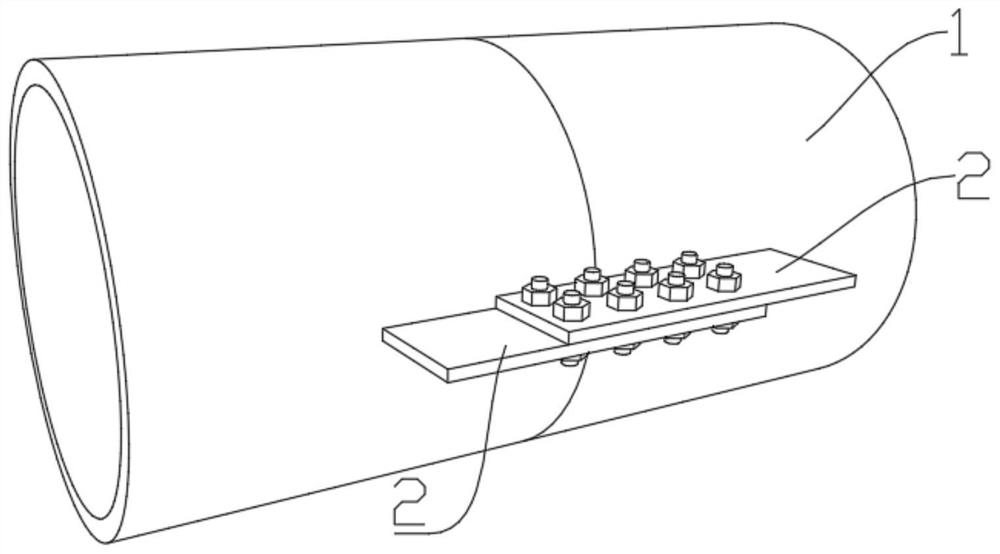

[0041] A temporary connection structure between truss-type steel pipe skeleton segments described in this embodiment is used to temporarily connect two axially adjacent skeleton main pipes 1, and the outer wall of the end of the skeleton main pipe 1 is provided with at least two A connection assembly, the connection assembly is evenly spaced along the circumference of the framework main pipe 1, and the connection assembly includes at least one connecting ear plate 2 arranged axially along the skeleton main pipe 1, two of the skeleton main pipes 1 The corresponding two connecting ear plates 2 are bolted. The number of the connecting components can be adjusted accordingly according to the force requirements of the actual structure, such as two, four, etc., but there should be at least two connecting components, and the number of connecting lugs 2 included in each connecting component is based on the design The needs are determined.

[0042] The bolts are ordinary bolts, the num...

Embodiment 2

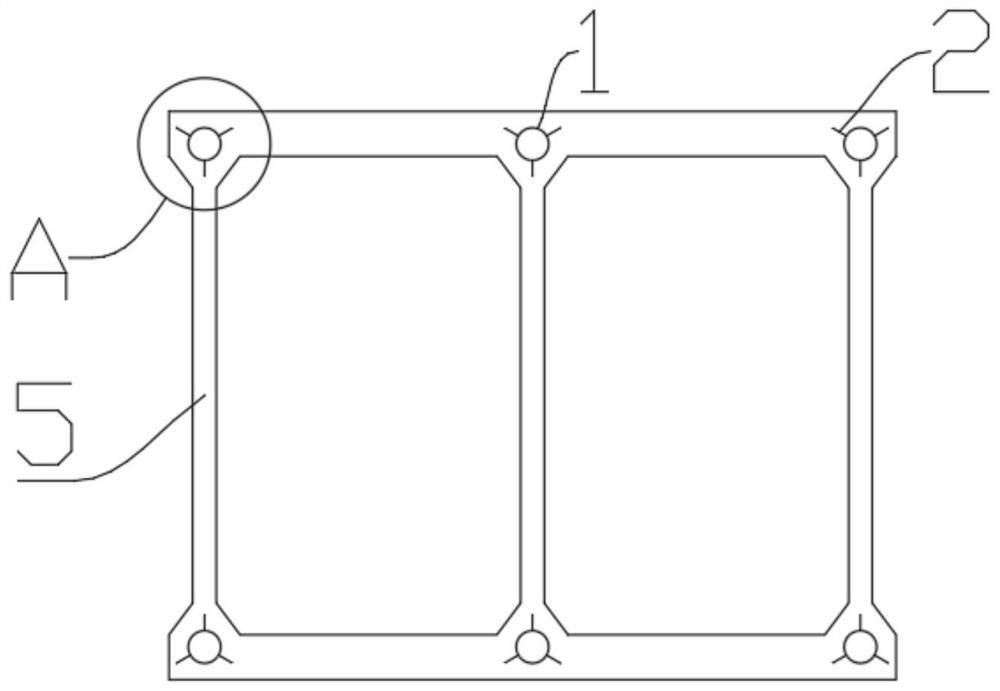

[0047] The temporary connection structure between the segments of a truss-type steel pipe skeleton described in this embodiment is roughly the same in structure as in Embodiment 1, the difference is that, as Figure 3-4 As shown, the outer wall of the end part of the framework main pipe 1 described in this embodiment is provided with three connecting assemblies, and the angle between two adjacent connecting assemblies is 120°. Of course, it is allowed to exist within ±5° Processing and installation errors, one of the connecting components points to the web 5 of the outsourcing concrete, that is, the height direction of the connecting component points to the middle of the thickness direction of the web 5, which is beneficial to the other two connecting components towards the outer concrete. The thick position, that is, the effective space corresponding to the outsourcing concrete section, can avoid secondary processing on the stressed structure beyond the connection structure of...

Embodiment 3

[0050] On the basis of Embodiment 1 or Embodiment 2, further, two guide plates 4 are connected to the inner side wall of one of the ends of the two butted skeleton main pipes 1, of course, three or four guide plates 4 can also be provided, Properly set according to the pipe diameter of the skeleton main pipe 1, the guide plate 4 is used to guide two skeleton main pipes 1 to dock when working at heights. If the guide plate 4 is a chamfered trapezoidal steel plate, the connection between the guide plate 4 and the inner side wall of the framework main pipe 1 can be single-sided fillet weld. The setting of described guide plate 4 sees Figure 6-7 , Image 6 The end face of the connecting ear plate 2 is aligned with the end face of the skeleton main pipe 1, Figure 7 The end face of the connecting ear plate 2 and the end face of the skeleton main pipe 1 are misplaced, and can be connected through the assembly plate 3 Image 6 not shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com