500kV compact-to-conventional line strain tower jumper drainage bus fitting

A compact, tower jumper technology, applied in the direction of adjusting/maintaining mechanical tension, cable suspension device, etc., can solve the problems of difficult implementation, low operation safety and reliability, poor shunt effect, etc., and achieve high operation reliability, Good converging effect and uniform current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

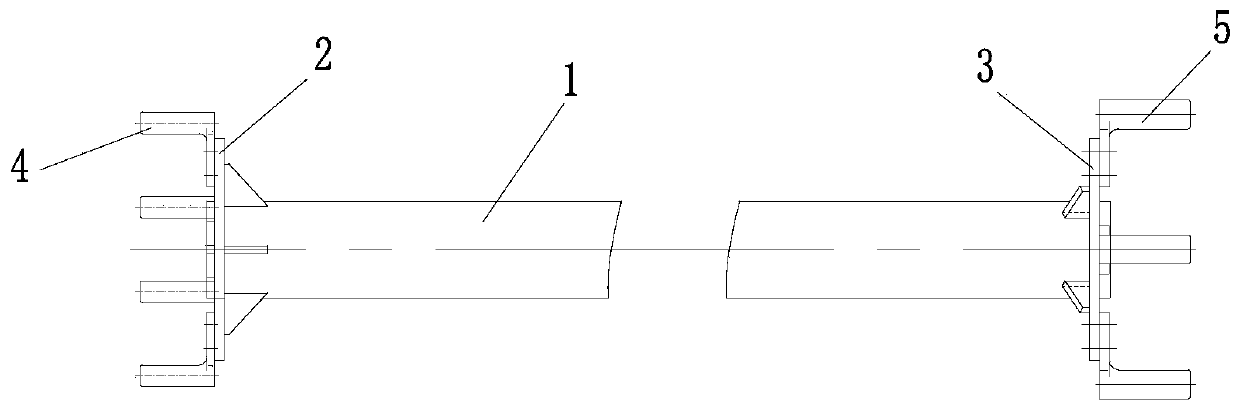

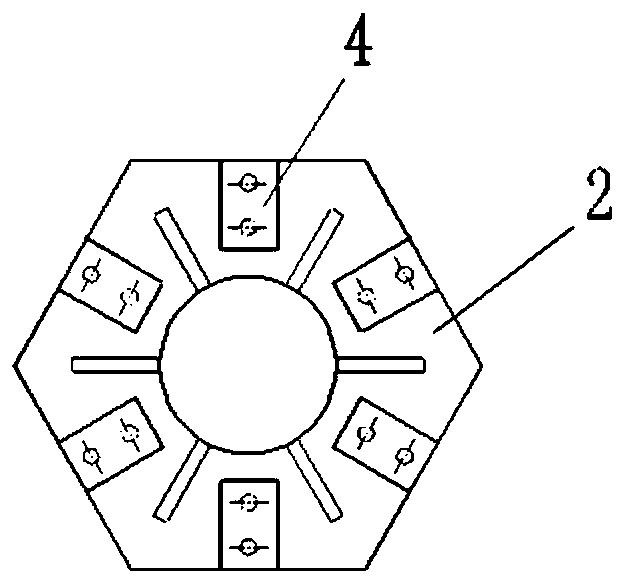

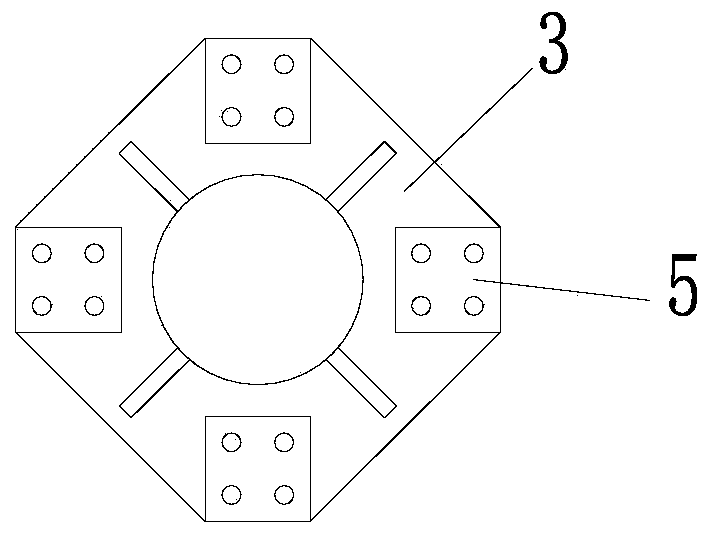

[0018] Refer to attached Figure 1-3 , this embodiment includes a six-split wire confluence plate 2 and a four-split wire confluence plate 3 connected to the two ends of the current-carrying aluminum tube bus 1, the six-split wire confluence plate 2 is provided with a six-split wire equipment clip 4, and the The outside of the four-split wire confluence plate 3 is provided with a four-split wire equipment clip 5, and the six-split wire equipment clip 4 is used to install a six-split wire (not shown in the figure) of a compact line, and the current collection of the six-split wire To the six-split wire confluence plate 2, the collected current is transported to the four-split wire confluence plate 3 through the current-carrying aluminum tube bus 1, and the four-split wire device clip 4 is installed with a conventional line four-split wire (not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com