Infusion bottle automatic shaking device for insulin intravenous injection

A technology for infusion bottles and insulin, which is applied in transportation and packaging, hypodermic injection equipment, shaking/oscillating/vibrating mixers, etc., and can solve problems such as laborious and troublesome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

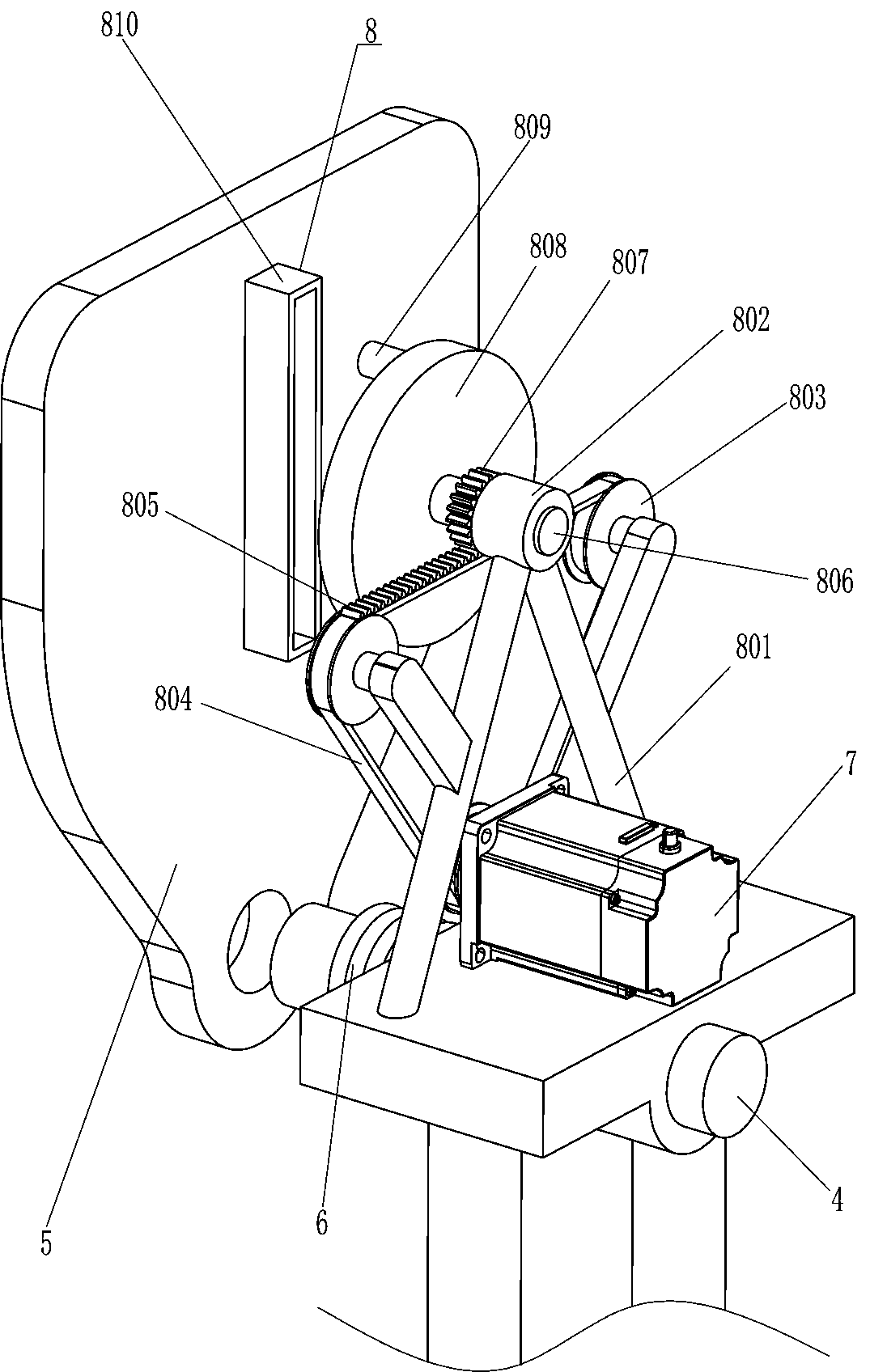

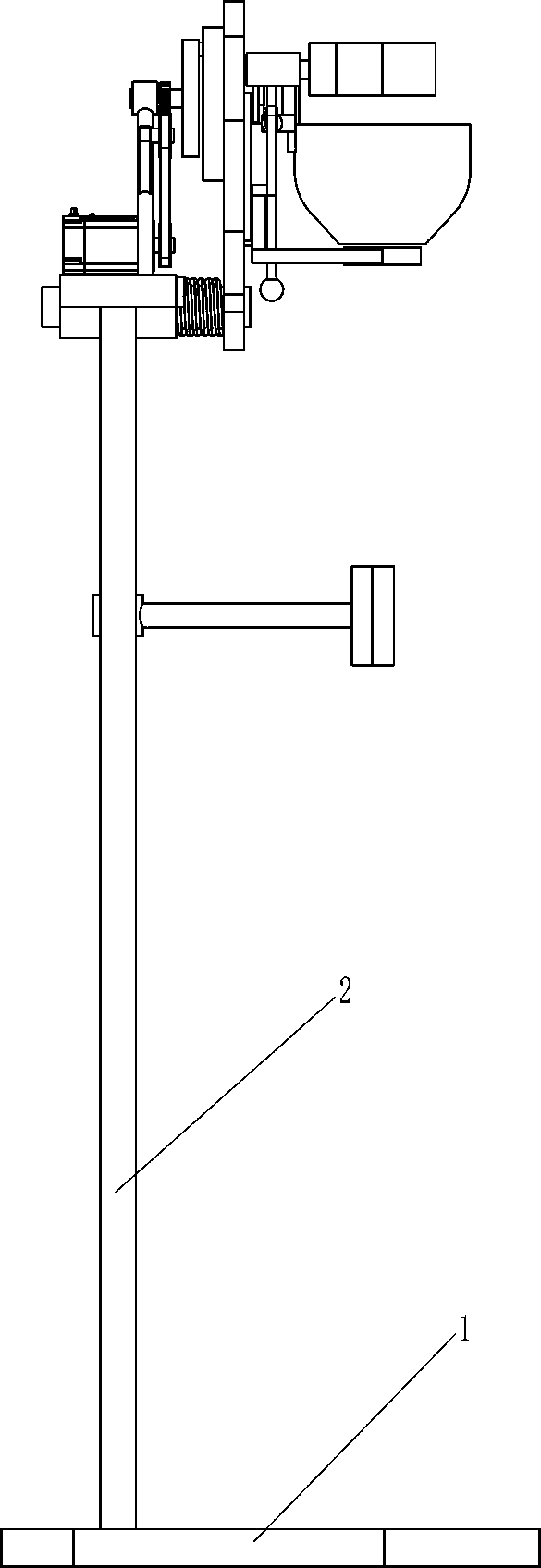

[0027] refer to Figure 1-Figure 8 , an automatic shaking device for an infusion bottle for insulin intravenous injection, comprising a bottom plate 1, a pole 2, a support plate 3, a first rotating shaft 4, a mounting plate 5, a torsion spring 6, a servo motor 7, a rotating assembly 8 and a fixing assembly 9 , two support rods 2 are fixedly connected to the left side of the top of the bottom plate 1, a support plate 3 is fixedly connected between the tops of the two support rods 2, a first rotating shaft 4 is connected to the middle of the bottom of the supporting plate 3 in a rotational manner, and the right end of the first rotating shaft 4 A mounting plate 5 is fixedly connected, a torsion spring 6 is connected between the left side of the mounting plate 5 and the right side of the support plate 3, the torsion spring 6 is set on the first rotating shaft 4, the left side of the mounting plate 5 is connected to the top of the support plate 3 There is a rotating assembly 8 bet...

Embodiment 2

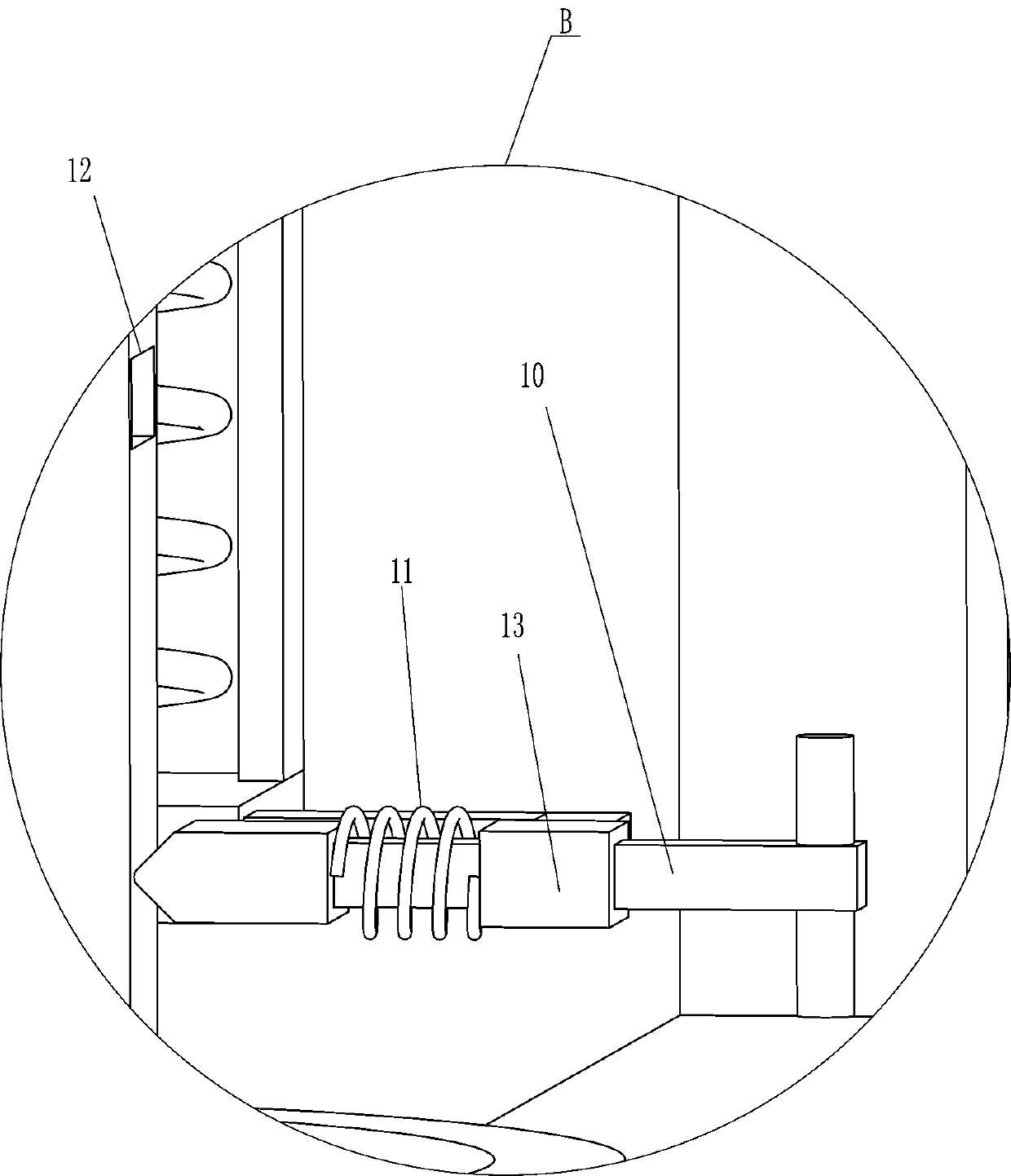

[0034] refer to Figure 5 and Figure 9 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a clamping rod 10, a fifth spring 11 and a guide sleeve 13 are also included, and the guide sleeve 13 is fixedly connected to the lower right side of the rear side of the guide rail 903, and the guide sleeve 13 inner sliding type is provided with clamping rod 10, and clamping rod 10 is positioned at T-shaped push rod 909 rear side, is wound with the fifth spring 11 between the front part of clamping rod 10 and the front side of guide sleeve 13, behind T-shaped push rod 909 A draw-in slot 12 is formed on the lower part of the side, and the draw-in slot 12 cooperates with the draw bar 10 .

[0035] Initially, the fifth spring 11 is in a compressed state. When the T-shaped push rod 909 moves downward, the T-shaped push rod 909 also drives the card slot 12 to move downward. When the card slot 12 moves down to the front side of the card rod 10 , d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com