A kind of plastic plate processing and trimming equipment

A technology of plastic board and edge trimming, which is applied in the field of plastic processing and can solve problems such as damage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

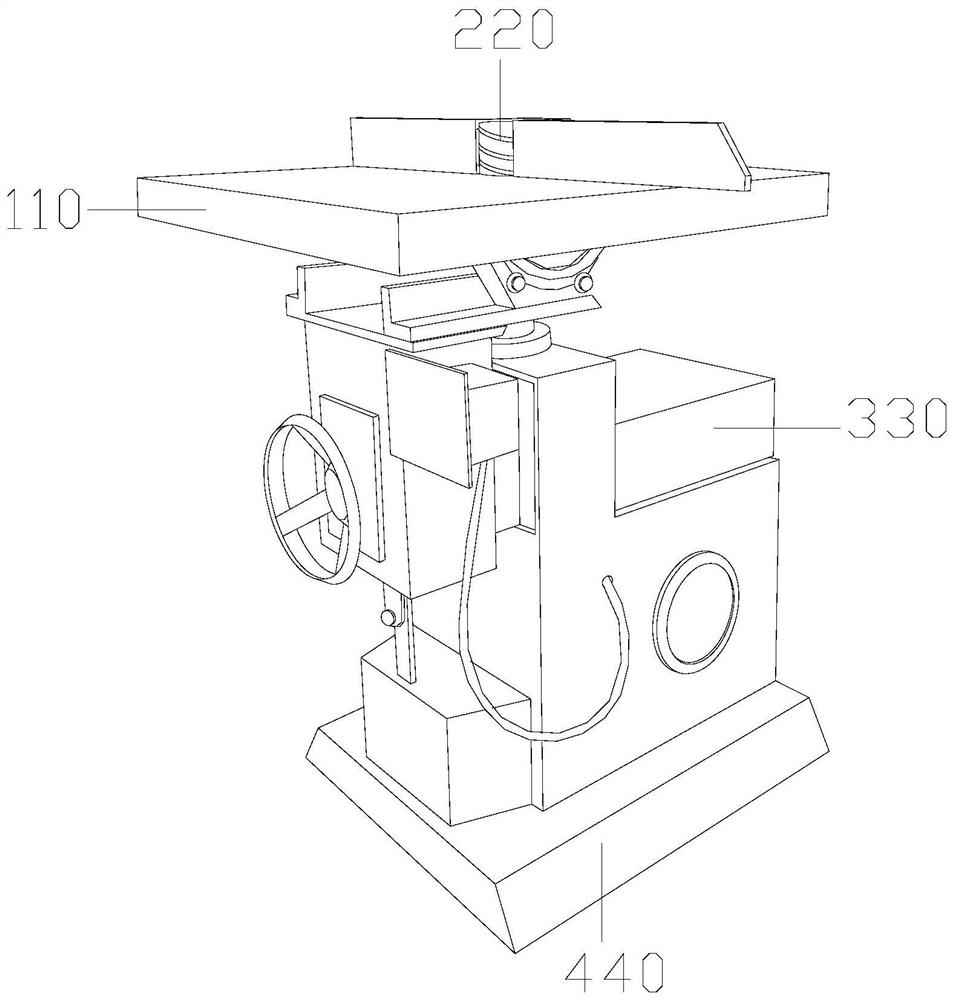

[0032] as attached figure 1 to attach Image 6 Shown:

[0033] The present invention provides a plastic board processing and trimming equipment, the structure of which includes a workbench 110 , a trimming wheel 220 , a control box 330 , and a base 440 .

[0034] The trimming wheel 220 vertically penetrates the inside of the workbench 110 , the bottom end of the workbench 110 is welded to the upper surface of the control box 330 , and the end of the control box 330 away from the workbench 110 is connected to the base 440 .

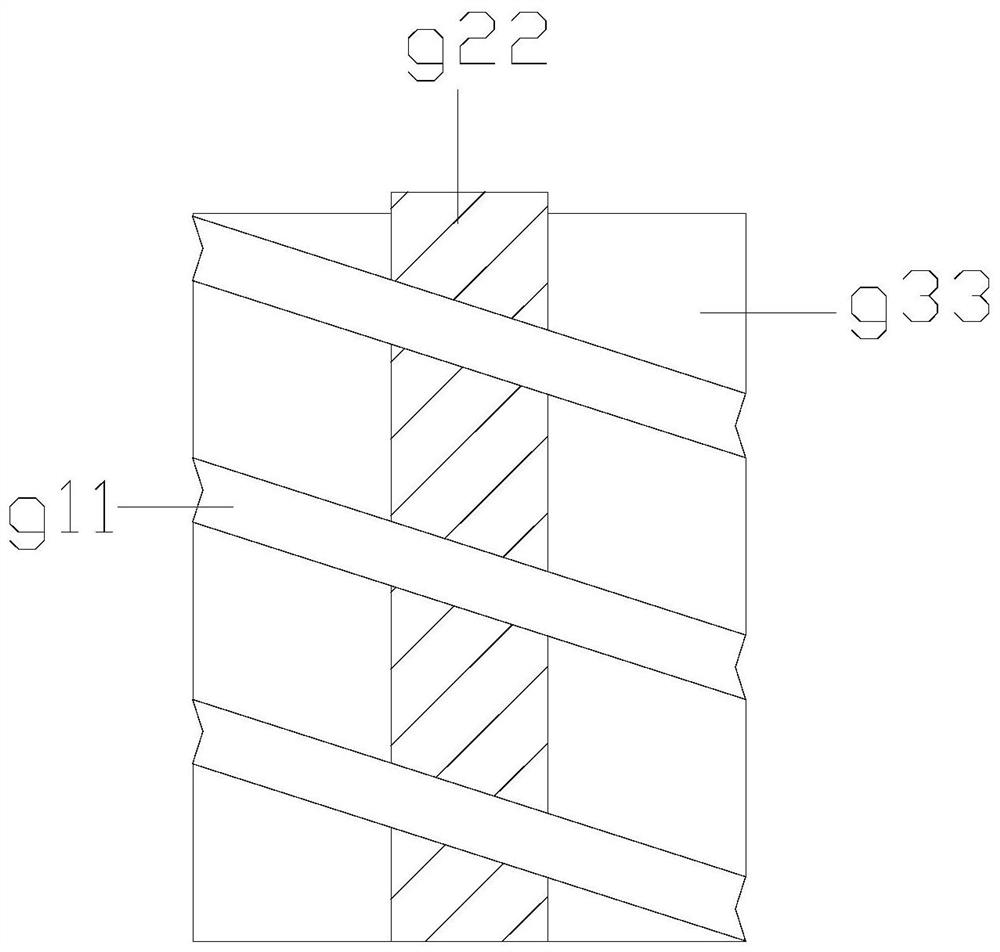

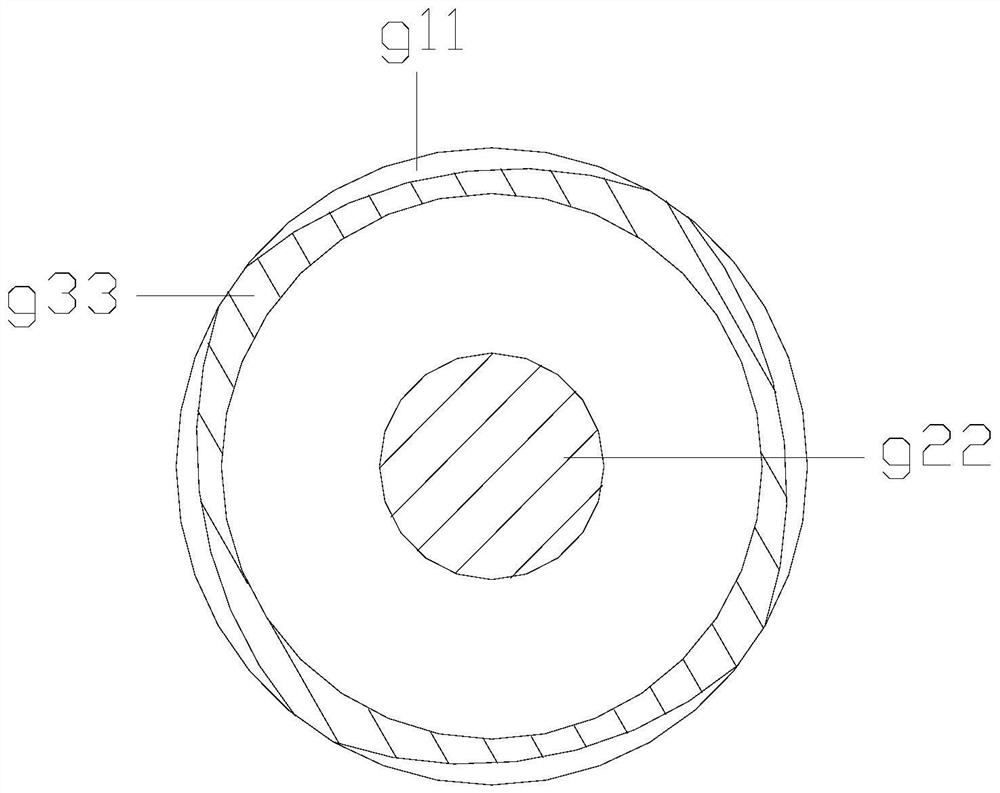

[0035] Wherein, the trimming wheel 220 includes a grinding path g11, a center column g22, and a grinding block g33. The grinding path g11 touches the surface of the grinding block g33. Located on the same axis as the grinding block g33, the winding state of the grinding track g11 is evenly distributed, the central column g22 fixes the center point of the overall rotation, and the grinding block g33 as a whole performs friction trimming against external o...

Embodiment 2

[0042] as attached Figure 7 to attach Figure 9 Shown:

[0043] Wherein, the grinding block g33 includes a pendulum angle 001 and an abutment angle 002, the abutment angle 002 is attached to the inner surface of the pendulum angle 001, four of the abutment angles 002 are provided and two form a group, and the pendulum angle There are two angles 001. The swing angle 001 is fixed at one position. When force is applied on both sides, it will be stretched. The angle 002 allows the external force to be better wrapped and displayed.

[0044] Wherein, the swing angle 001 includes a swing angle x11, a clamping block x22, and a total force layer x33, and the swing angle x11 is installed between two clamping blocks x22 at intervals, and the clamping block x22 and the inner wall of the total force layer x33 connected, the swing angle x11 is against the inner wall of the total force layer x33, the clamping block x22 is a quadrilateral structure, there are five swing angle x11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com