Electronic candle machine core wire frame

A technology of electronic candles and cores, which is applied in the direction of electric light sources, lighting devices, lighting and heating equipment, etc., can solve the problems of large volume of electronic candles, difficulty in accommodating the core, small volume of electronic candles, etc., and achieve good exhaust effect, Space-saving and not easy to loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

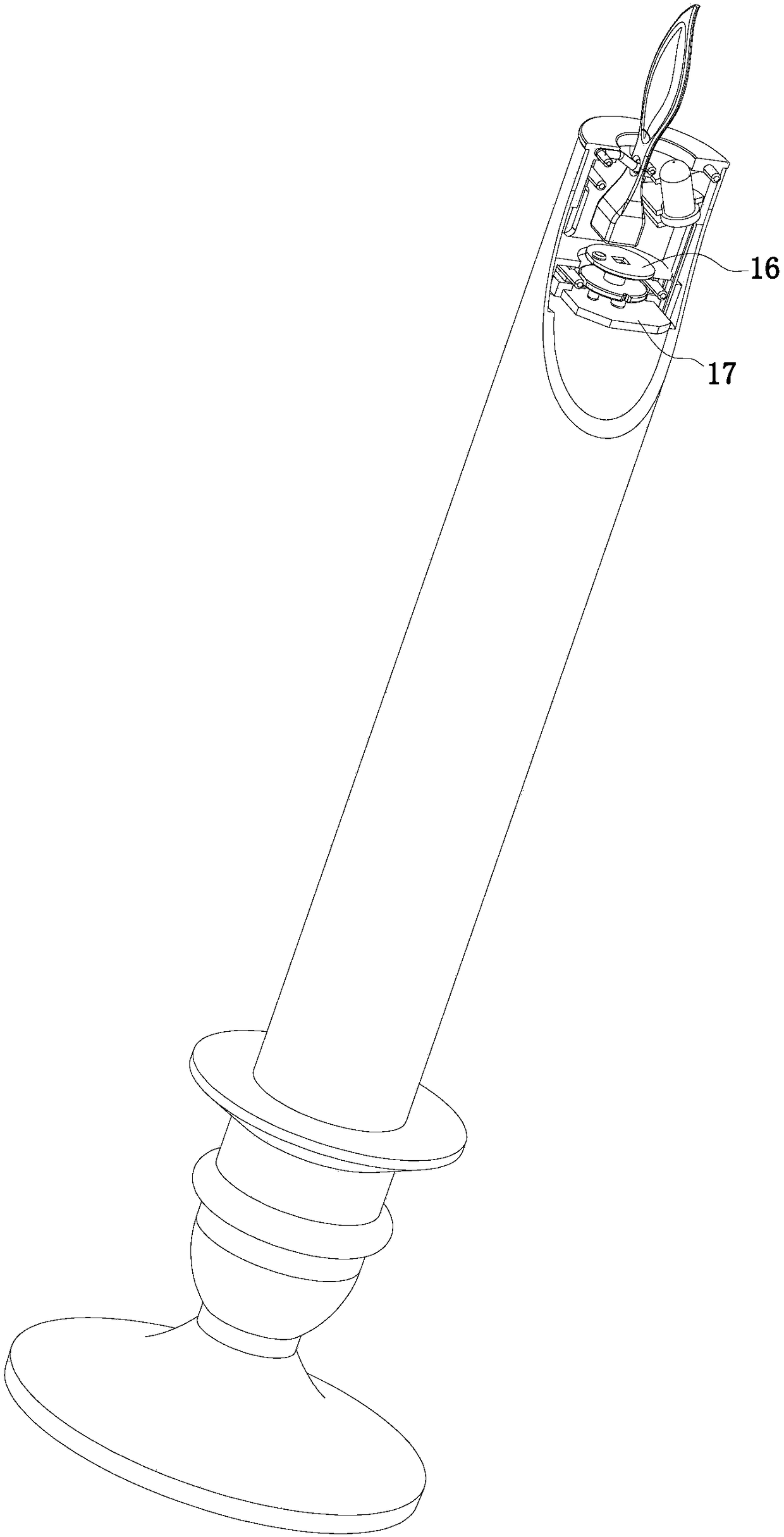

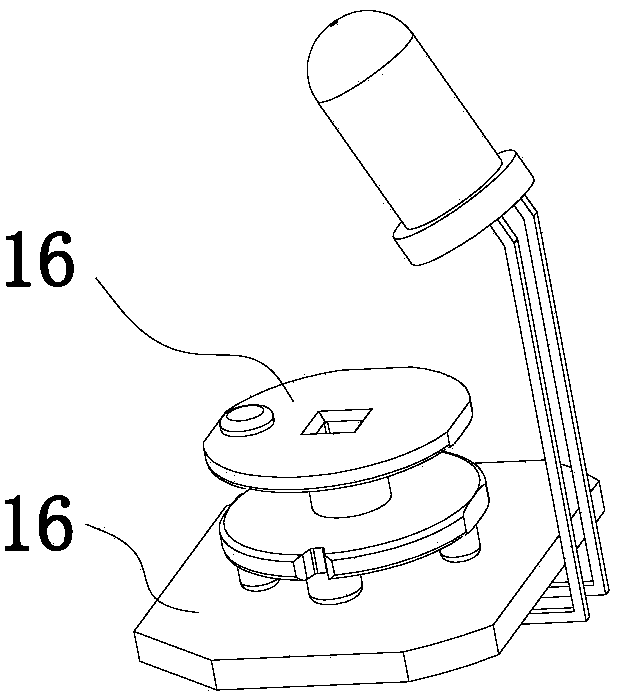

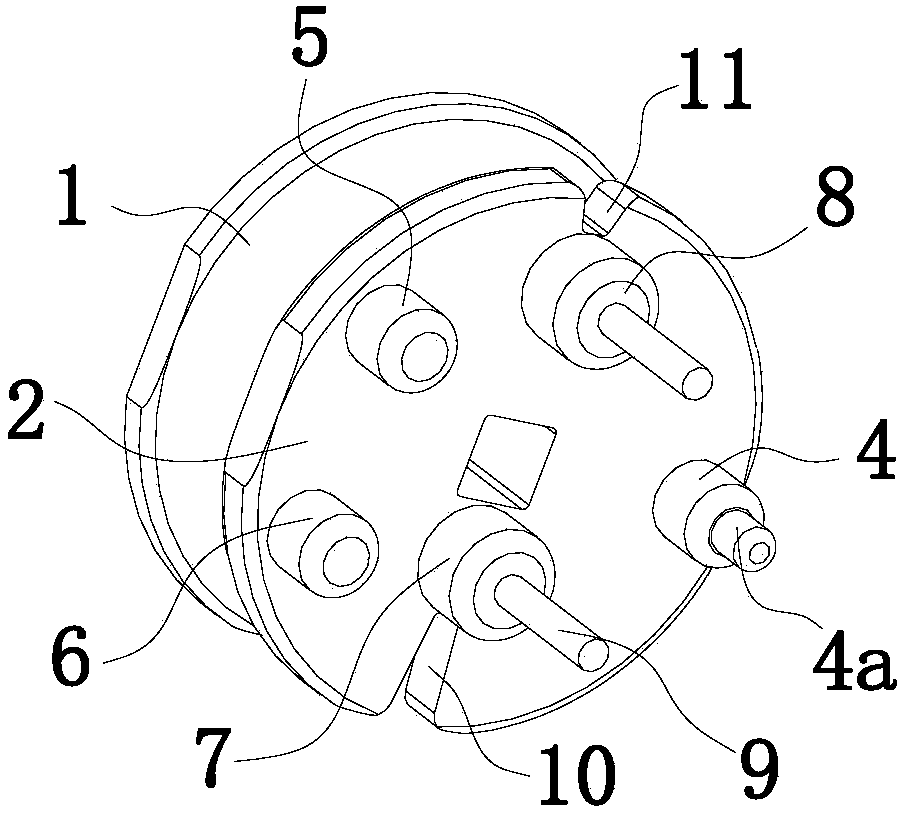

[0026] refer to Figure 1 to Figure 7 The shown electronic candle movement frame includes an integrally formed upper side plate 1, a lower side plate 2 and a winding shaft 3 between them, the upper side plate 1 and the lower side plate 2 are parallel to each other and It is a disc-shaped mechanism. The upper side plate 1, the lower side plate 2 and the winding shaft 3 are coaxial. Vertical and outwardly extending positioning posts, the axes of the three positioning posts share a cylindrical surface, the cylindrical surface is coaxial with the winding shaft 3, and the lower side plate 2 is also provided with a first plug-in post 7 perpendicular to it and extending outwards And the second plug-in post 8, the first plug-in post 7 and the second plug-in post 8 are all provided with a pin 9 coaxial with it and extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com