A fixation plate for avulsion fracture of posterior cruciate ligament tibial insertion

A technique of cruciate ligament and plate fixation, applied in the direction of fixator, outer plate, internal bone synthesis, etc., can solve the problems of posterior cruciate ligament injury, high pressure, affecting the effect of fracture fixation, etc., to achieve firm and reliable fixation, prevent displacement or the effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

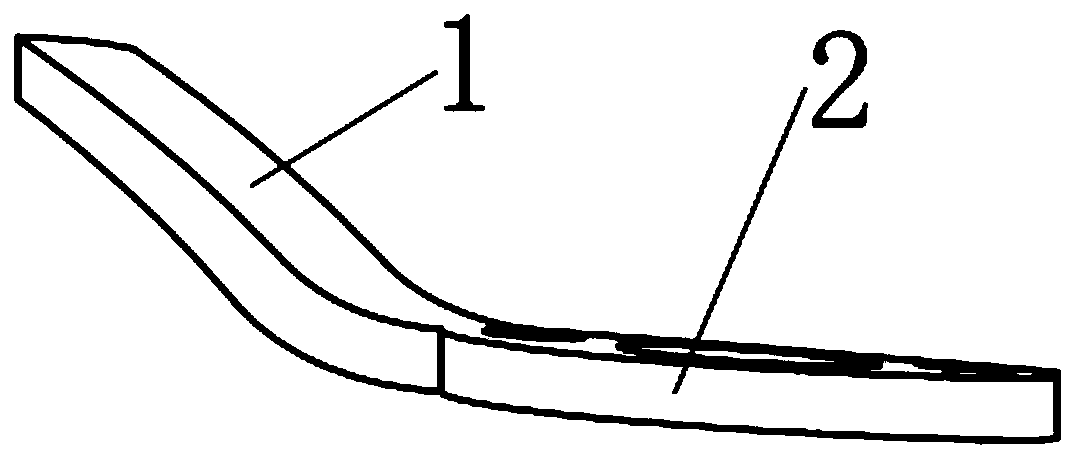

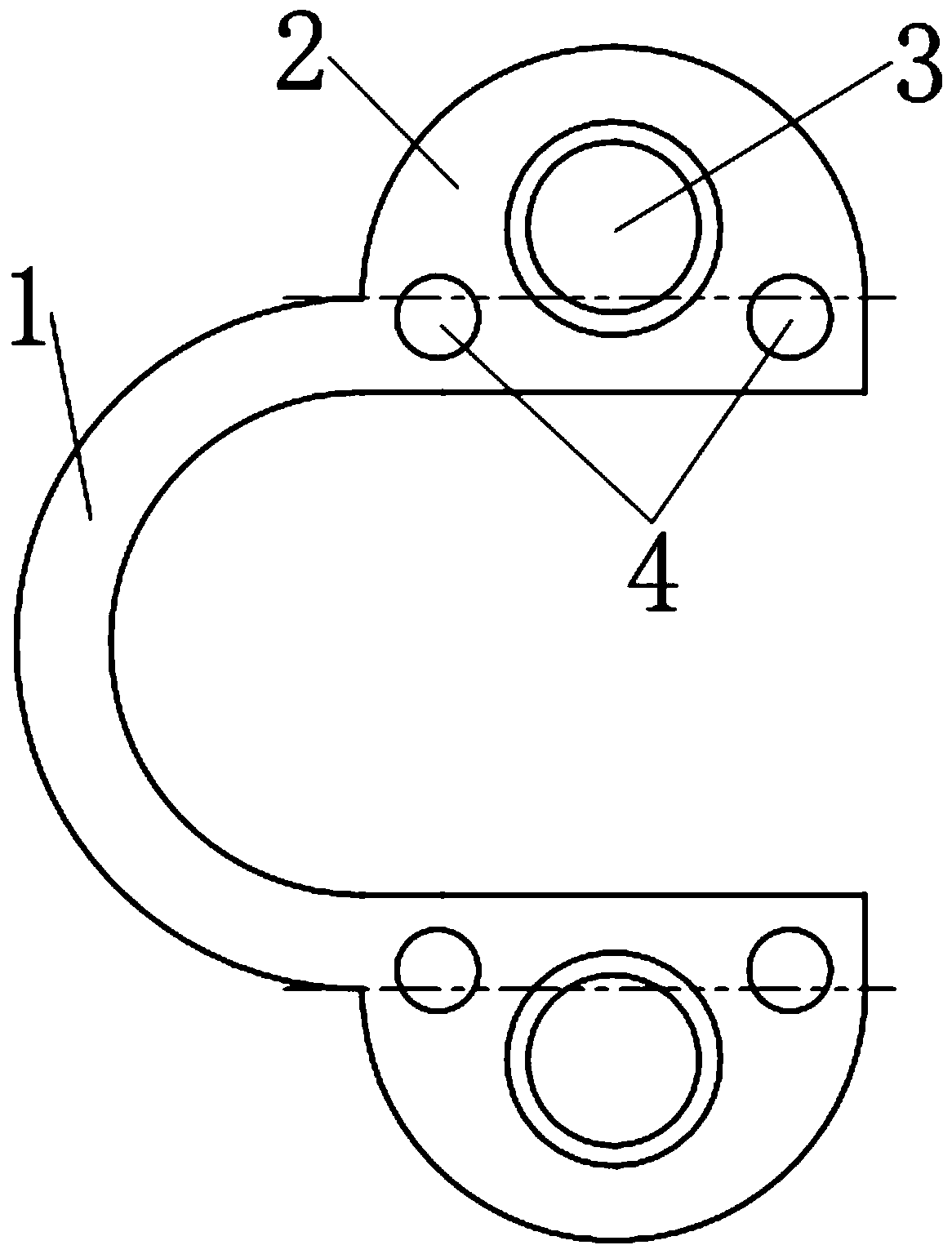

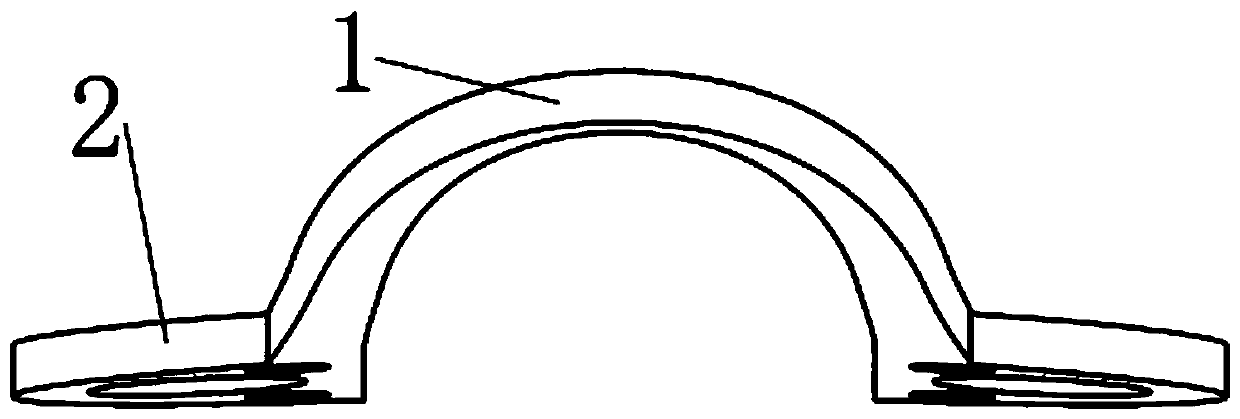

[0023] see Figure 1~6 and combine Figure 7 , the posterior cruciate ligament tibial insertion point avulsion fracture fixation plate in this example is made of titanium alloy, and the thickness is 1.5mm, and this fixed steel plate has a U-shaped pressing plate 1 around the posterior cruciate ligament 8 tibial insertion points (see Figure 7 , shown as the back view of the tibia), the curved part of the U-shaped pressing plate 1 is covered around the front part of the posterior cruciate ligament 8 tibial insertion, and the two sides extend to the rear along the edges on both sides of the posterior cruciate ligament 8 tibial insertion The rear part of the tibial insertion of the cruciate ligament 8; the inner side of the U-shaped pressure plate 1 is an arc that coincides with the root of the posterior cruciate ligament 8, and the lower surface is the tibial condyle at the front of the posterior cruciate ligament 8 tibial insertion The bone surface of the interspine 10 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com