Solid aluminum electrolytic capacitor with high heat dissipation performance and preparation method of capacitor

A technology of aluminum electrolytic capacitors and heat dissipation performance, which is applied in the direction of solid electrolytic capacitors, capacitors, electrical components, etc., can solve the problems of capacitor temperature rise, capacitor scrapping, and capacitor heat dissipation efficiency, and achieve the effect of protecting the core package and accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

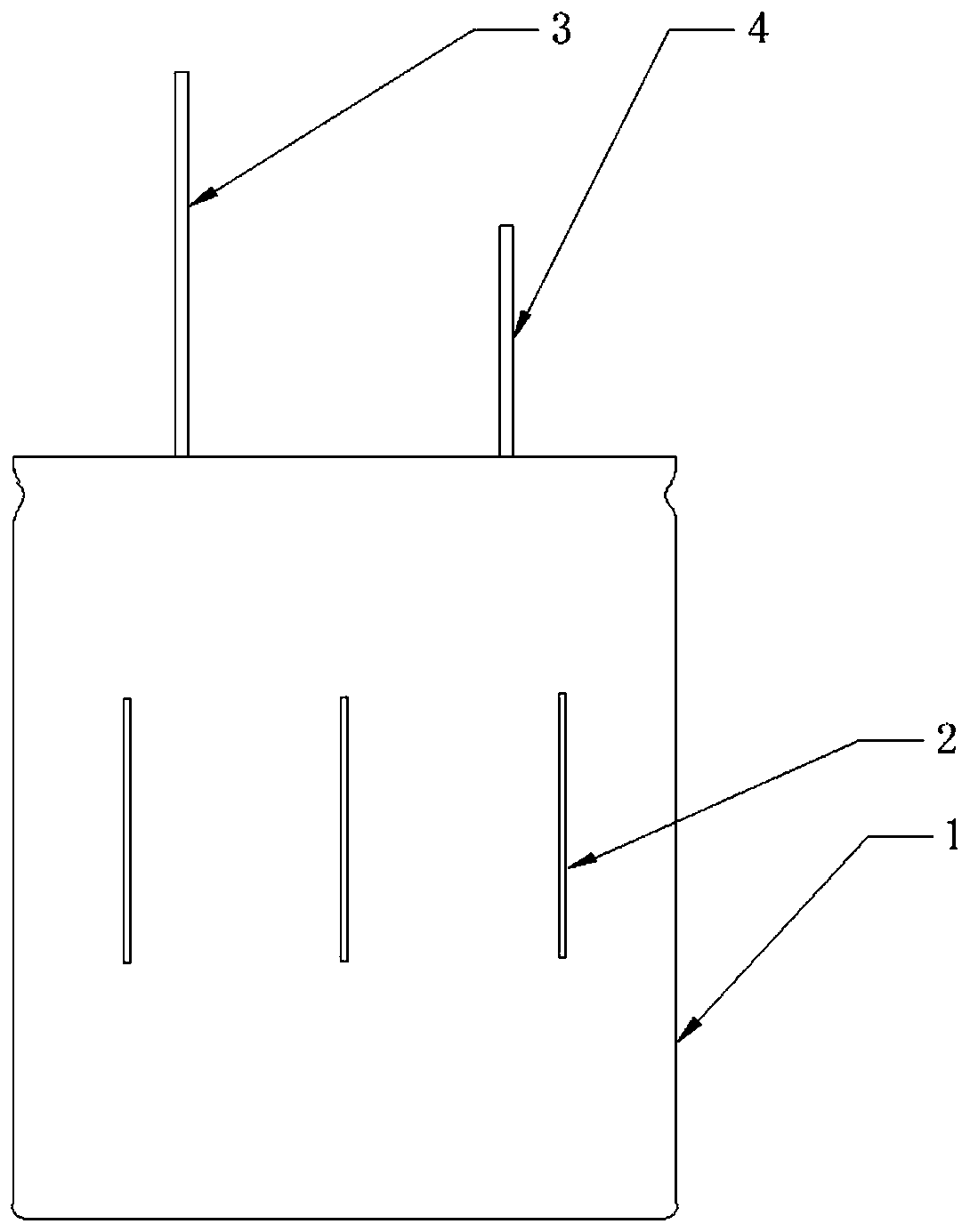

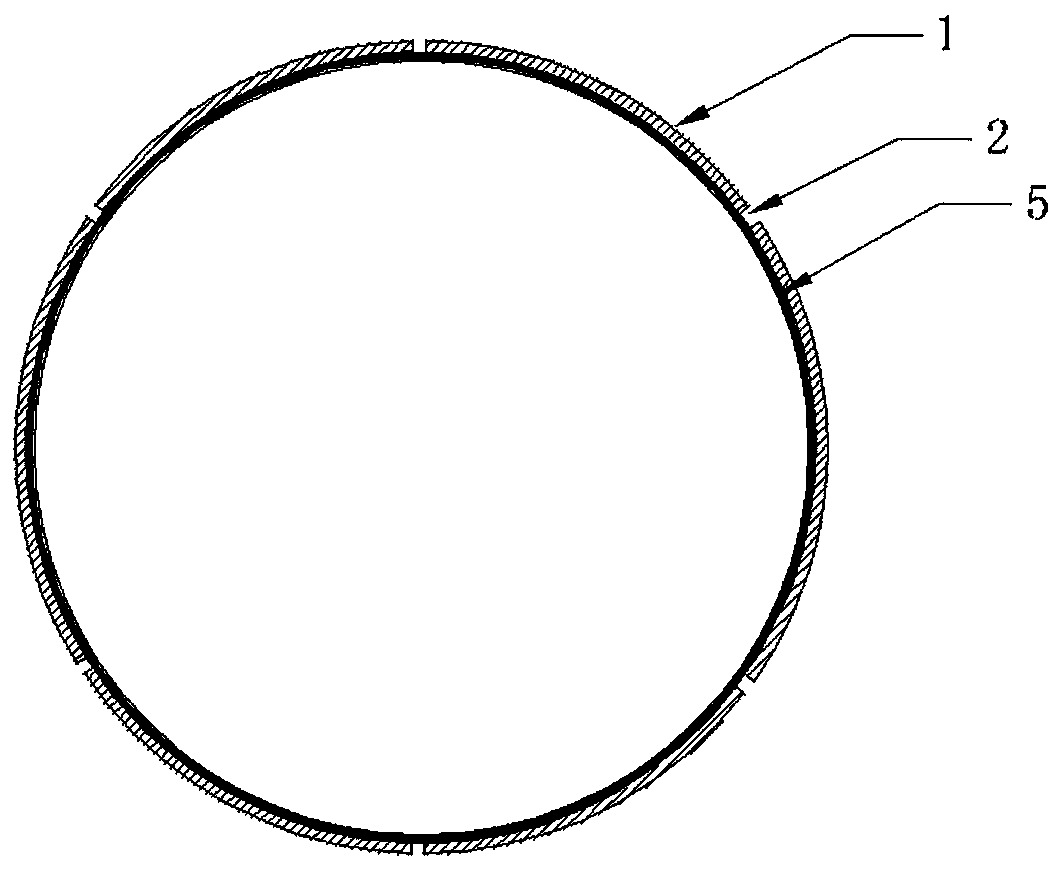

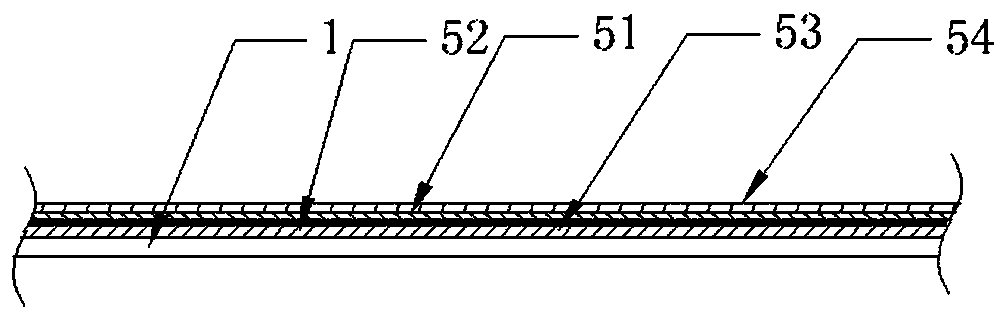

[0030] Such as figure 1 and figure 2 A solid aluminum electrolytic capacitor with good heat dissipation performance is shown, including a casing 1, a core package and a rubber plug. The core package is sealed and arranged in the casing 1 through the rubber plug. A waterproof and breathable membrane 5 is formed on the inner wall. The heat dissipation holes 2 are arranged in the longitudinal direction of the housing 1, and the heat dissipation holes 2 are elongated. In other embodiments, the existing waterproof and breathable membrane can be directly attached to the inner wall of the shell opening and fixed so that the waterproof and breathable membrane completely blocks the through hole; the heat generated by the core package can be dissipated through the waterproof and breathable membrane in time , but the external dust cannot enter the shell, and the waterproof and breathable membrane isolates the core pack from the shell and protects the core pack.

[0031] In this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com