Bearing seat structure used for preventing water from entering cold roll bearing in cold area of hot rolling layer

A technology for bearing seat and cold area, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., which can solve the problems of high probability of water ingress in bearing seats, loss of grease, dead rollers of bearings, etc., and improve equipment reliability Performance and service life, improvement of weak points of equipment, and reduction of inspection load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

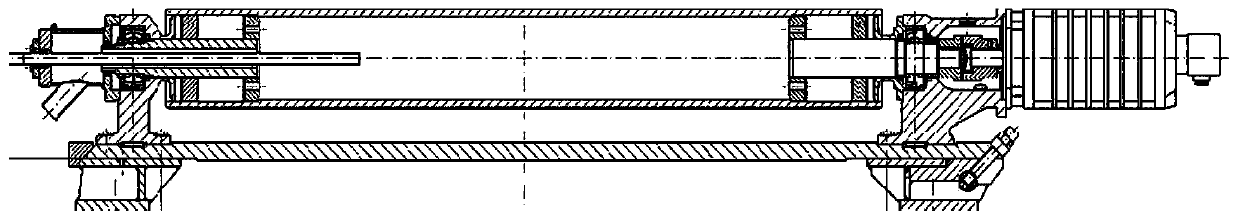

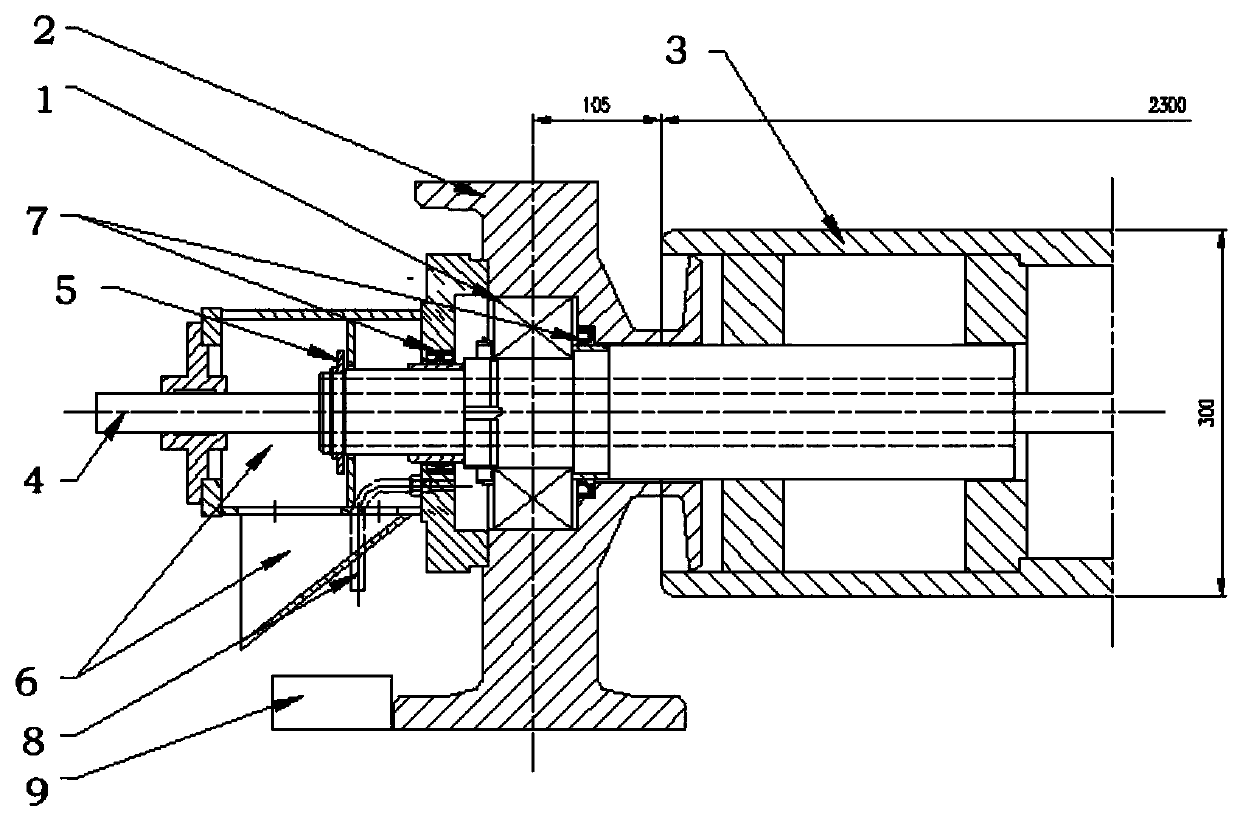

[0020] like figure 2 As shown, a chock structure for preventing water from entering the cold roll bearing in the cold area of the hot rolling layer, including a bearing 1, a chock 2, an inner cooling roll 3, a water inlet pipe 4 and a drainage device, the inner cooling roll 3 One end of the inner chamber cooperates with the water inlet pipe 4, and the inner cooling roller 3 is installed in the bearing housing 2 of the hot rolling production line through the bearing 1. The 4 ends of the water inlet pipe are provided with a drainage device, and the drainage device is provided with a drainage chamber. The bearing housing 2 is connected, and the bottom side of the drainage cavity is provided with a water outlet, and the joint between the water inlet pipe 4 and the inner cooling roller 3 is provided with a water retaining ring 5 to keep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com