Full-automatic book jacket flap folding machine

A fully automatic, rack-mounted technology, applied in book binding flattening machines, book binding, printing, etc., can solve the problems of low production efficiency of books, and achieve the effects of convenient and convenient transposition, accurate vertical height, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

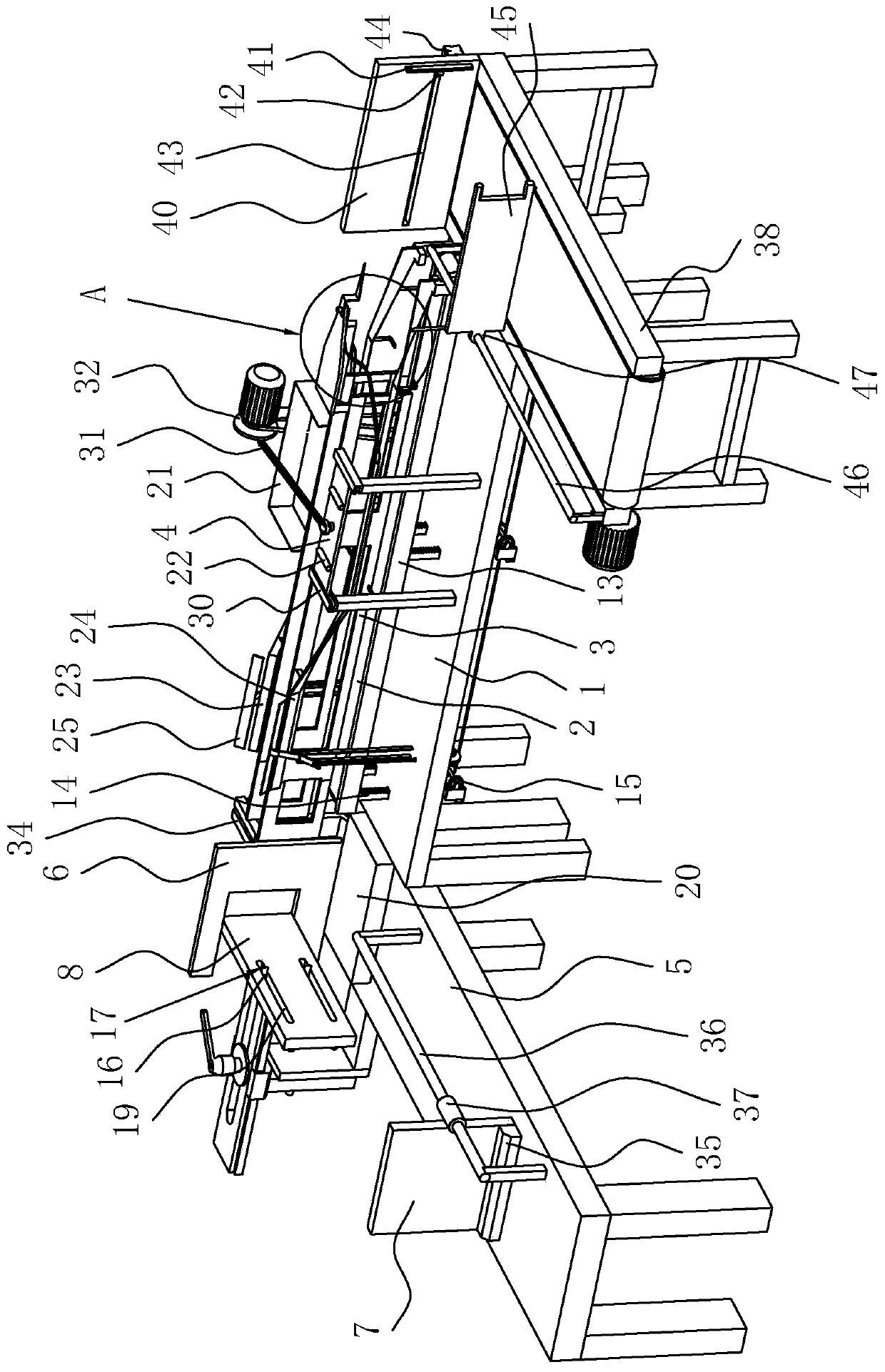

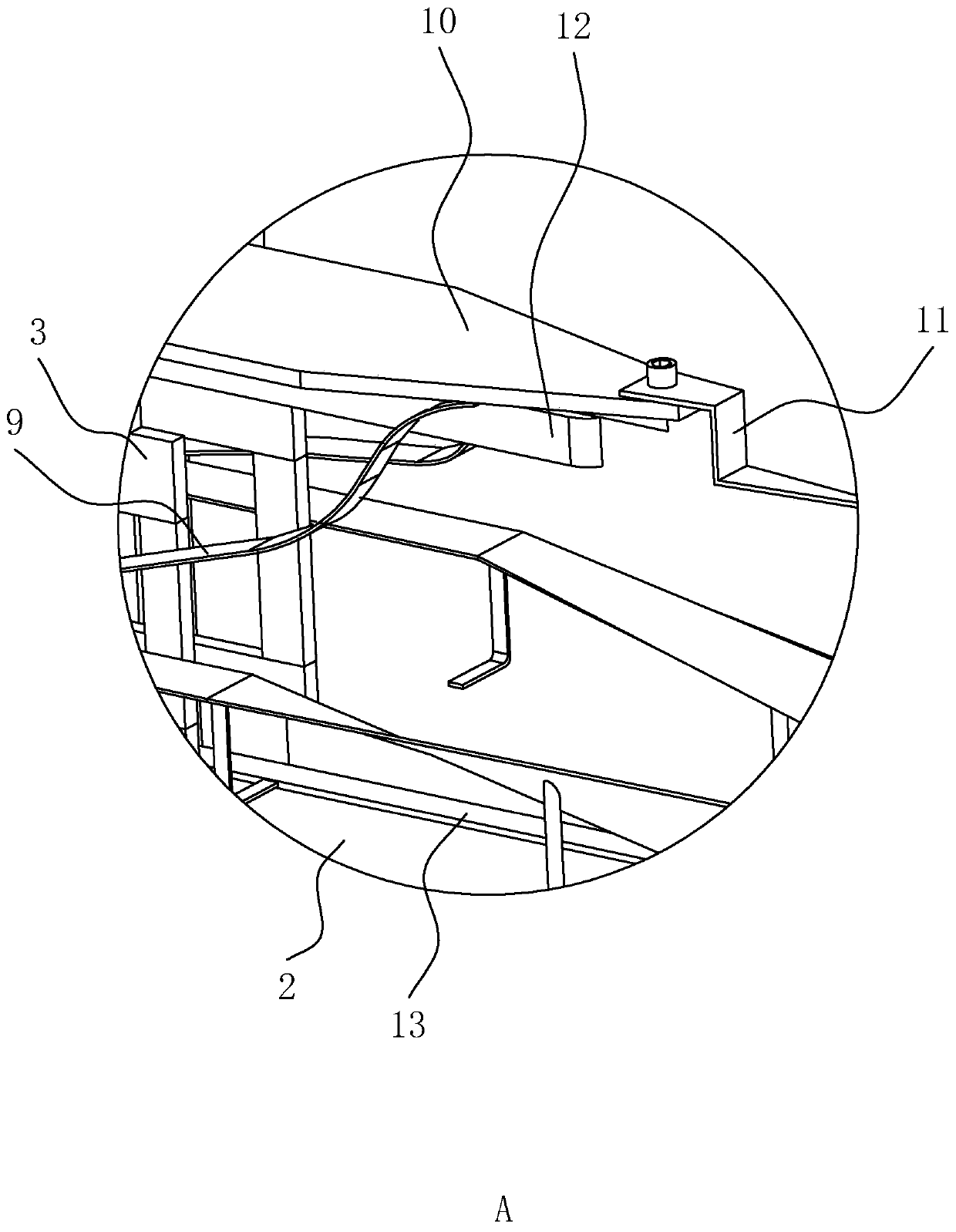

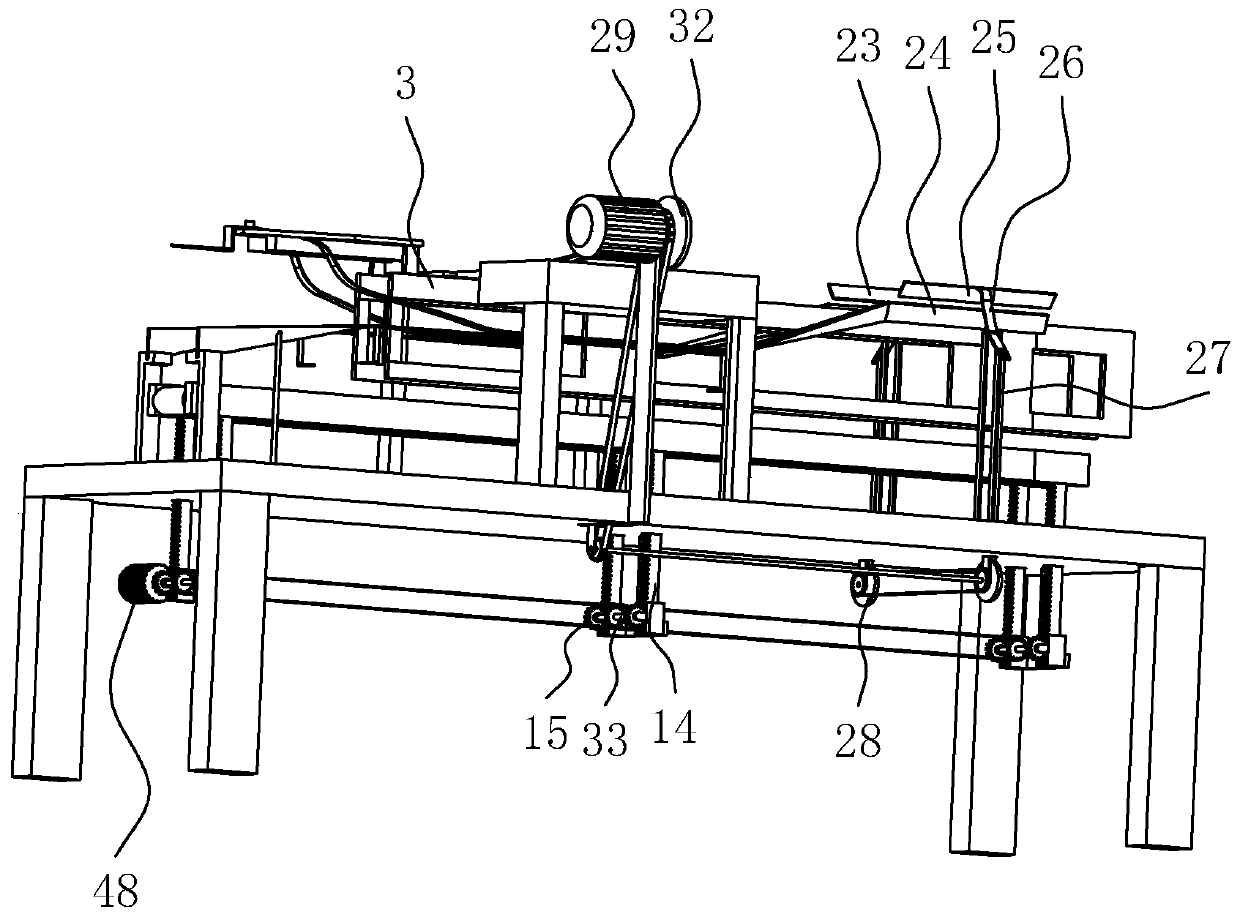

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0044] refer to figure 1 , is a kind of full-automatic book sealing and closing machine disclosed by the present invention, and comprises elongated frame 1, and the frame 1 is provided with the bookshelf 13 along its length direction, and the bookshelf 13 is provided with along its length direction. The book-feeding conveyor belt 2, the two ends in the length direction of the bookshelf 13 are rotatably connected with conveying rollers (not shown in the figure), the book-feeding conveyor belt 2 is stretched and wrapped on the outer peripheral sides of the arc surfaces of the two conveying rollers, and one end of the bookshelf 13 is A stepper motor (not shown in the figure) whose output end is fixed coaxially with one of the conveying rollers is fixedly connected; the frame 1 is erected above the book-feeding conveying belt 2 along its length direction and is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com