Lifting conveying equipment for electric power well maintenance

A technology of lifting and conveying and power wells, applied in the direction of lifting devices, etc., can solve problems such as accidents, stepping on the soles of the feet, easy slipping of hands, etc., and achieve the effect of reducing the probability of accidents and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

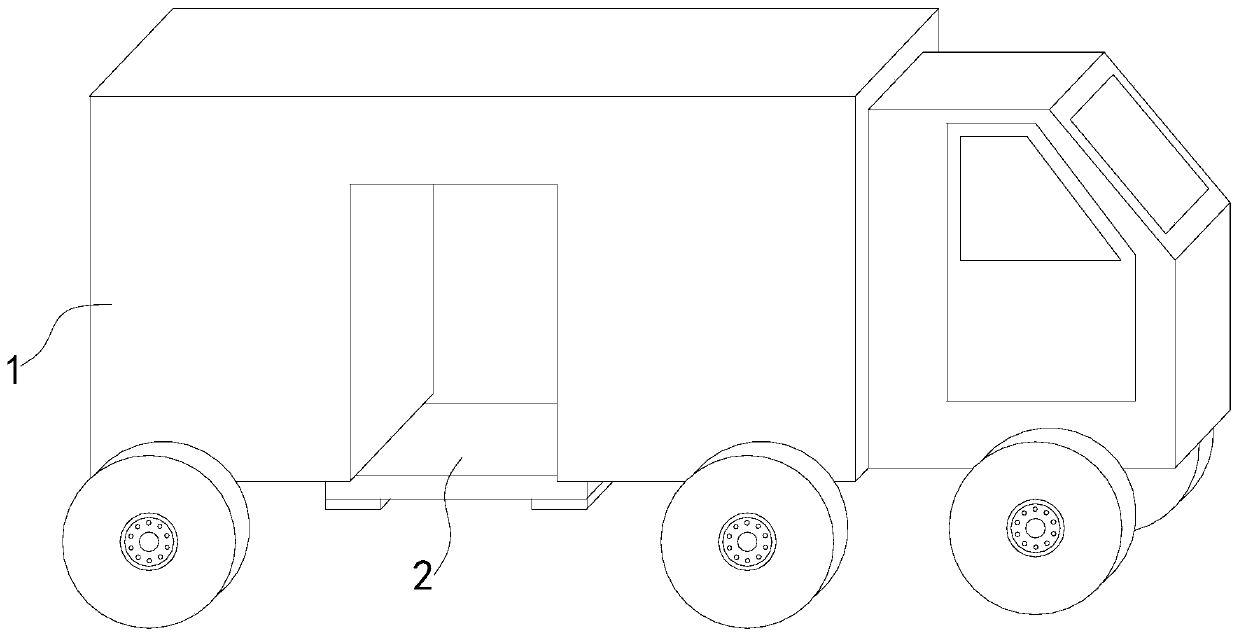

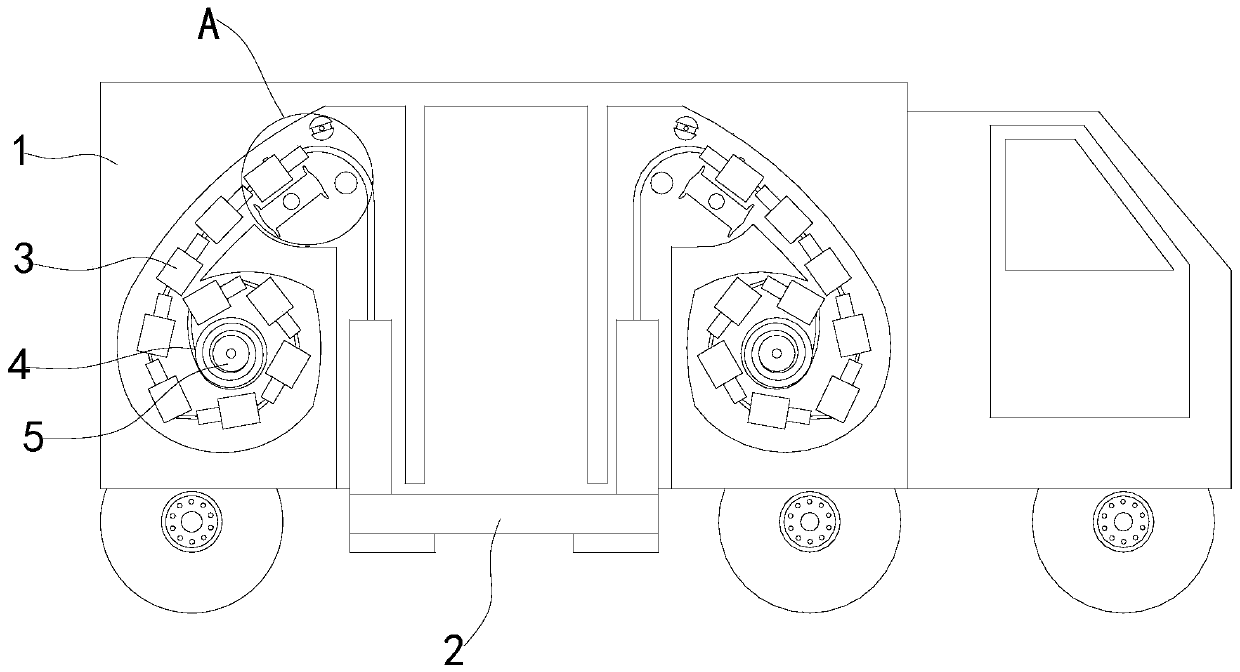

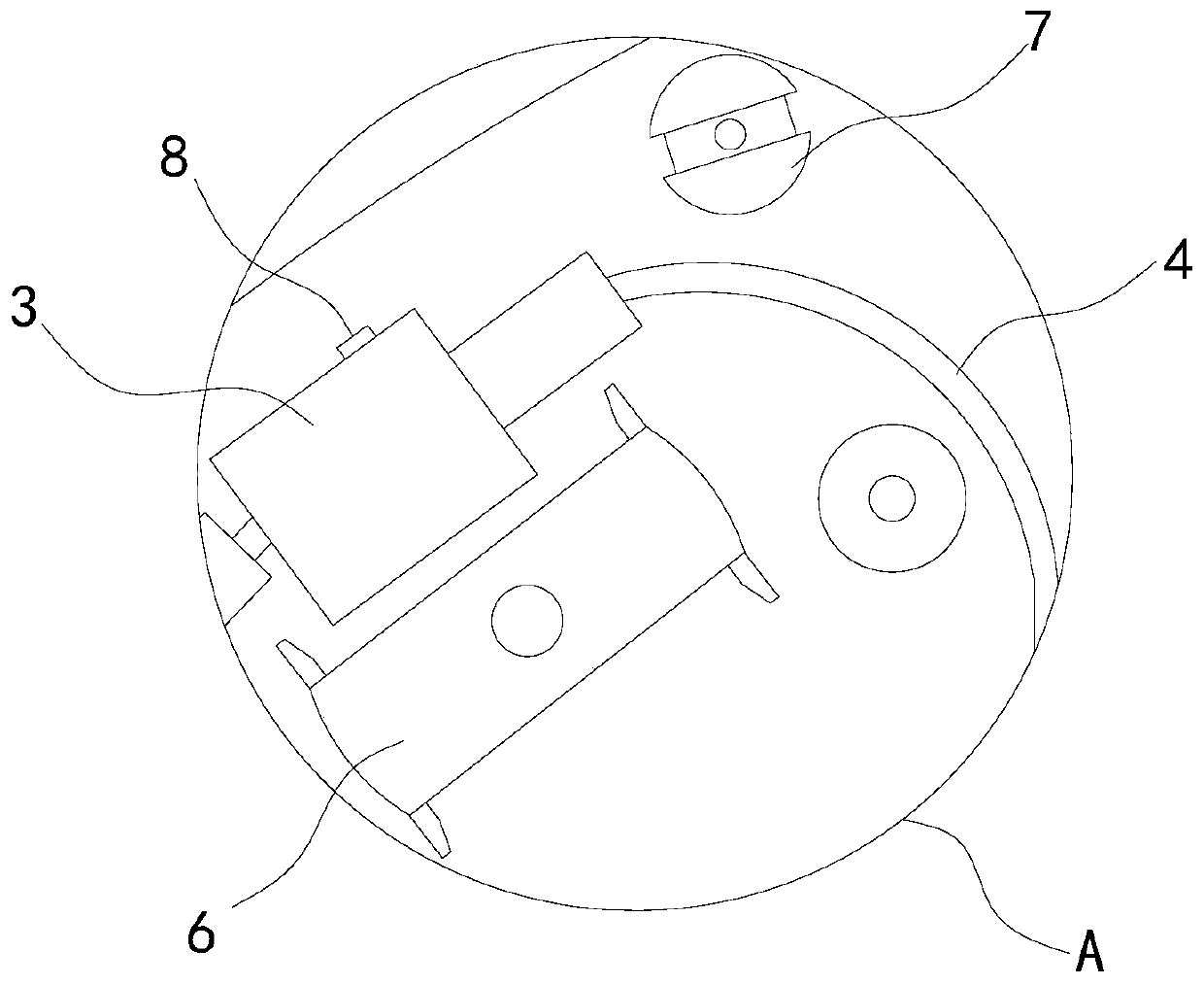

[0029] see Figures 1 to 9 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a lifting and conveying equipment for electric well maintenance.

[0030] A lifting and conveying equipment for power well maintenance, comprising a device main body 1, a lifting platform 2 is movably installed at the lower end of the device main body 1, a connecting rope 4 is fixedly installed on both sides of the lifting platform 2, and a stabilizing block 3 is movably installed on the outside of the connecting rope 4.

[0031] In a specific implementation, a sheave 5 is fixedly installed inside the device main body 1, and the connecting rope 4 is fixedly connected to the outside of the sheave 5, so that the sheave 2 can be used to rotate and control the distance that the connecting rope 4 moves outward, thereby controlling the lifting platform 2. Move up and down to facilitate maintenance personnel to enter and leave the power well.

[0032] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com