Fabric expanding and conveying system for tire chord fabric drawing zone

A tire curtain and conveying system technology, which is applied in textile, textile, papermaking, loom, etc., can solve the problems of low efficiency and high labor intensity, and achieve the effect of high efficiency, uniform mesh and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

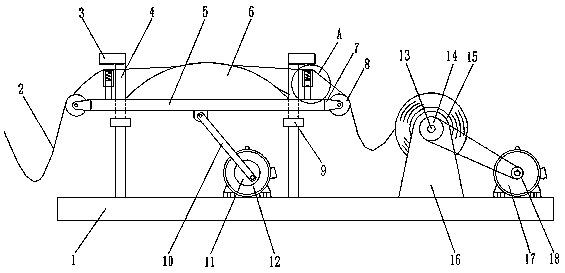

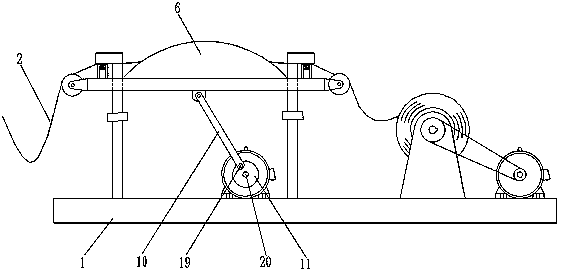

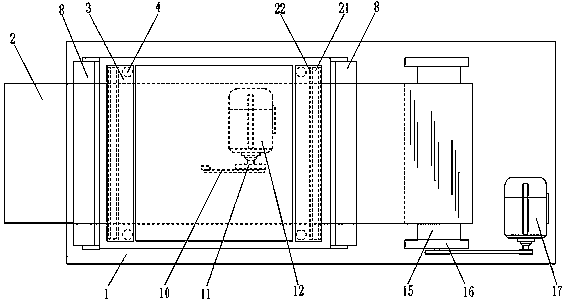

[0043] This embodiment is further optimized on the basis of Embodiment 1, specifically:

[0044] The base 1 is provided with a reel assembly and a second motor 17 at the rear ends of the two groups of guide rods 4. The reel assembly includes a roller 15 and a roller support 16. The roller support 16 is fixedly connected to the upper end of the base 1. The roller 15 is provided with a roller 13. The roller shaft 13 is rotatably connected to the top of the roller bracket 16, and the roller shaft 13 is connected to the second motor 17 in transmission.

[0045] By adding the reel assembly and the second motor 17, on the one hand, the effect of dragging the cord fabric 2 above the raised part 6 can be realized, and on the other hand, the stretched cord fabric 2 can be rolled onto the roller 15 for collection. , so that the present invention is more flexible and convenient.

[0046] In addition, a first pulley 14 is installed on the roller 13, a second pulley 18 is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com