Multifunctional wearable polymer/MXene compound fabric heater and preparation method thereof

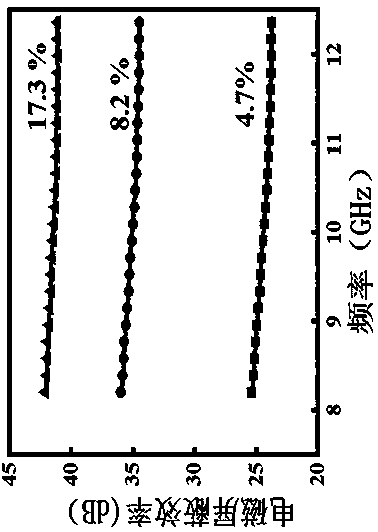

A technology of composite fabrics and polymers, applied in the directions of plant fibers, textiles and papermaking, fiber types, etc., can solve the problems of lack of wearability, flame retardant, antibacterial and electromagnetic shielding effects, etc., to meet wearable needs, preparation method The effect of simplicity, good breathability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

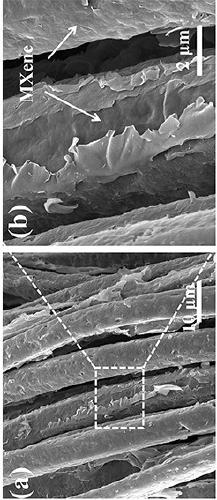

[0036] A preparation method of a multifunctional wearable polymer / MXene composite fabric heater, comprising the following steps:

[0037] (1) Pretreatment, soak the polymer-based fabric in 5-20 wt% NaOH solution at 50-90 °C and stir for 1-4 h, then wash the soaked polymer-based fabric with ion water until the pH value is Steps 6-8, preparing a pretreated polymer-based fabric;

[0038] (2) Prepare the etching solution. Stir 1-100 g of LiF powder and 100-3000 mL of 6-15 mol / L HCl solution in a polytetrafluoroethylene cup at room temperature for 30-60 minutes to obtain the original Bit HF etchant;

[0039] (3) To prepare the MXene solution, add 1-100 g of MAX phase powder into the HF etching solution, and react with magnetic stirring for 20-30 h at a temperature of 20-50 °C and a rotational speed of 100-1000 rpm to obtain the reaction product; after diluting the prepared reaction product with deionized water, pour it into a centrifuge tube and centrifuge at a speed of 3000-5000...

Embodiment 1

[0043] A preparation method of a multifunctional wearable polymer / MXene composite fabric heater, comprising the following steps:

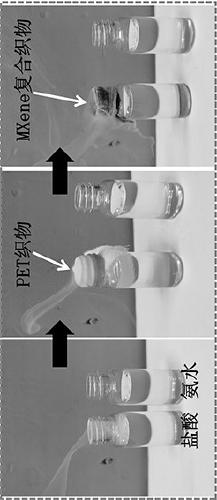

[0044] (1) Pretreatment, soak commercial polyester fabric (PET) in 10 wt% NaOH solution, stir at 70 °C for 2 h, then wash with deionized water until the pH value of the PET fabric is 6, and obtain pretreated PET fabric. fabric;

[0045] (2) To prepare etching solution, put 10 g of LiF powder and 200 mL of 12 mol / L HCl solution in a Teflon cup and stir for 30 min at room temperature to prepare HF etching solution;

[0046] (3) To prepare MXene solution, 10 g of MAX phase powder (MAX phase powder is Ti 3 AlC 2 、Ti 2 At least one of AlC) was added to the HF etching solution, and magnetically stirred at 35 °C and 500 rpm for 24 h to obtain the reaction product; the prepared reaction product was diluted with deionized water and centrifuged at 3500 rpm 5 min, remove the centrifuged supernatant, and repeat the centrifugation until the pH value ≥ 6 to ...

Embodiment 2

[0049] A preparation method of a multifunctional wearable polymer / MXene composite fabric heater, comprising the following steps:

[0050] (1) Soak the PET fabric in 10 wt% NaOH solution, stir at 70 °C for 2 h, and then wash it with deionized water until the pH value of the PET fabric is 6 to obtain a pretreated PET fabric;

[0051] (2) Stir 10 g of LiF powder and 200 mL of 12 mol / L HCl solution at room temperature for 30 min to prepare an etching solution;

[0052] (3) Add 10 g of MAX phase powder into the etching solution, stir magnetically at 35 °C and 100 rpm for 24 h, dilute the reaction product with deionized water and centrifuge at 3500 rpm for 5 min to remove the The supernatant was centrifuged repeatedly until the pH value was ≥ 6 to obtain the precipitate MXene; add deionized water to the precipitate MXene, sonicate for 10 min and centrifuge at 3500 rpm for 5 min to obtain a concentration of 10 mol / L MXene solution;

[0053] (4) Soak the pretreated PET fabric in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com