Modified wool fabric and its preparation method

A wool and fabric technology, applied in the field of modified wool fabric and its preparation, can solve the problems of cumbersome and complicated preparation methods, environmental pollution of flame retardants, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] According to a second aspect of the present invention, there is also provided a method for preparing the above-mentioned modified wool fabric, comprising the following steps:

[0068] (a) After coating the graphene oxide solution on two surfaces of the wool fabric, dry to obtain the wool fabric with a graphene oxide layer formed on the surface;

[0069] (b) coating the polyethyleneimine solution on the surface of the wool fabric with the graphene oxide layer, drying, to obtain the wool fabric with the graphene oxide layer and the polyethyleneimine layer formed on the surface;

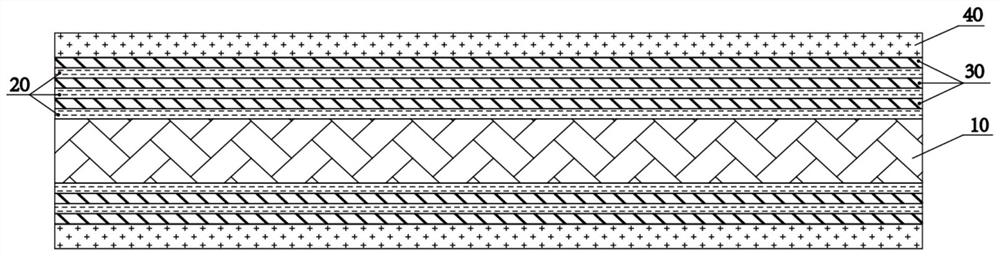

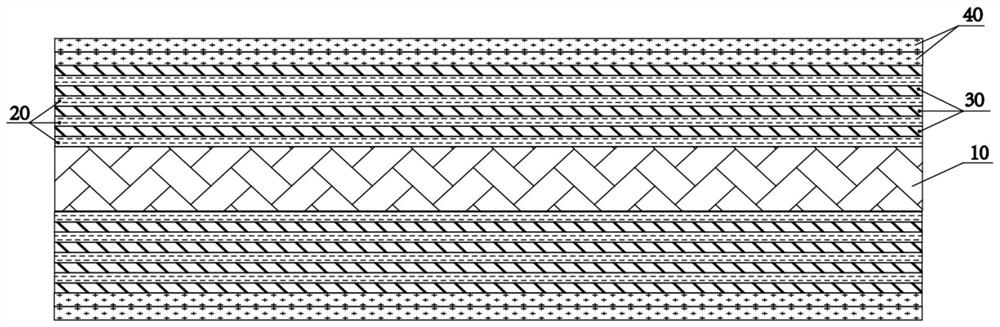

[0070] (c) repeating step (a) and step (b) several times, so that both surfaces of the woolen fabric form a composite layer in which graphene oxide layers and polyethyleneimine layers are alternately arranged;

[0071] (d) Coating the polyphosphate amine solution on the surface of the wool fabric with the composite layer, drying to obtain the modified wool fabric; or, irradiating the surface of t...

Embodiment 1

[0113] This embodiment provides a modified wool fabric, in which a composite layer and two layers of polyphosphate amine layers are sequentially arranged on both surfaces of the wool fabric from inside to outside;

[0114] Wherein, the composite layer includes a graphene oxide layer and a branched polyethyleneimine layer, the graphene oxide layer and the branched polyethyleneimine layer are alternately arranged, and the bottom layer of the composite layer near the wool fabric surface is a graphene oxide layer, away from The top layer of the composite layer on the wool fabric surface is a branched polyethyleneimine layer.

[0115] The preparation method of the modified wool fabric provided by the present embodiment comprises the following steps:

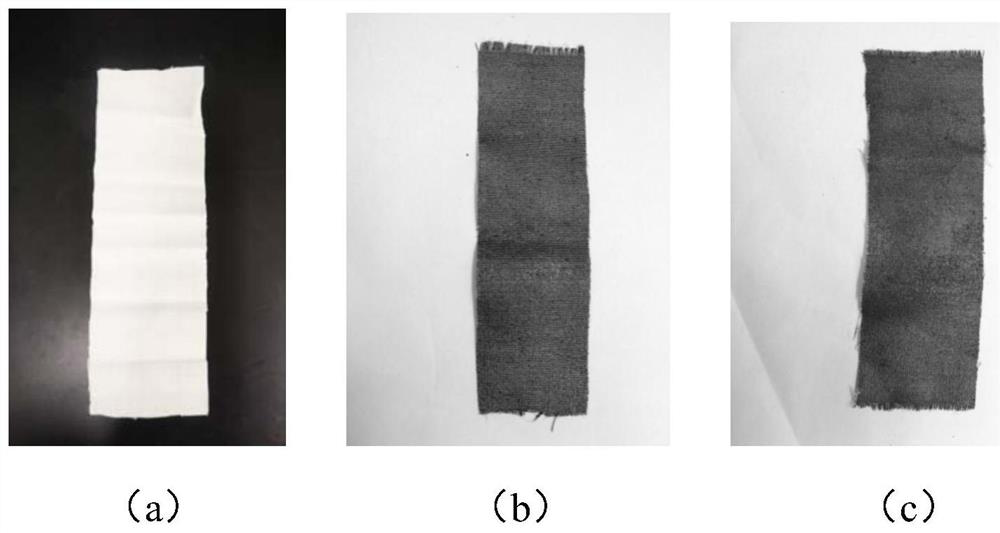

[0116] (a) After the wool fabric is cleaned with deionized water, spray a graphene oxide solution of 5 mg / mL and a pH value of 7 to the two surfaces of the wool fabric, wherein the spraying pressure is 2bars, and the graphene oxide so...

Embodiment 2

[0121] This embodiment provides a modified wool fabric, except that the graphene oxide layer in the carbon material layer is replaced by a graphene layer, the rest of the structure and composition are the same as in embodiment 1.

[0122] The preparation method of the modified wool fabric provided in this example, except that step (d) is different from Example 1, steps (a), (b) and (c) are all the same as Example 1;

[0123] Step (d) comprises the following steps: irradiating the surface of the wool fabric with the composite layer with ultraviolet light so that the graphene oxide layer is completely converted into a graphene layer, the time of ultraviolet light irradiation is 13h, and the voltage of the light source of ultraviolet light irradiation is 220V, the frequency of the light source is 50Hz, the power of the light source is 18W, and the light distance is 30cm, and then spray 20mg / mL polyphosphate amine solution to form the polyphosphate amine layer, wherein the spraying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com