Settlement adjusting method and system suitable for ballastless track with retaining shoulder

A ballastless track and adjustment system technology, applied in the field of rail transit, can solve problems such as the inability to achieve large track adjustments, increase the operating cost of high-speed railways, and fail to meet adjustment needs, so as to improve flexibility and convenience, reliable settings, The effect of high smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

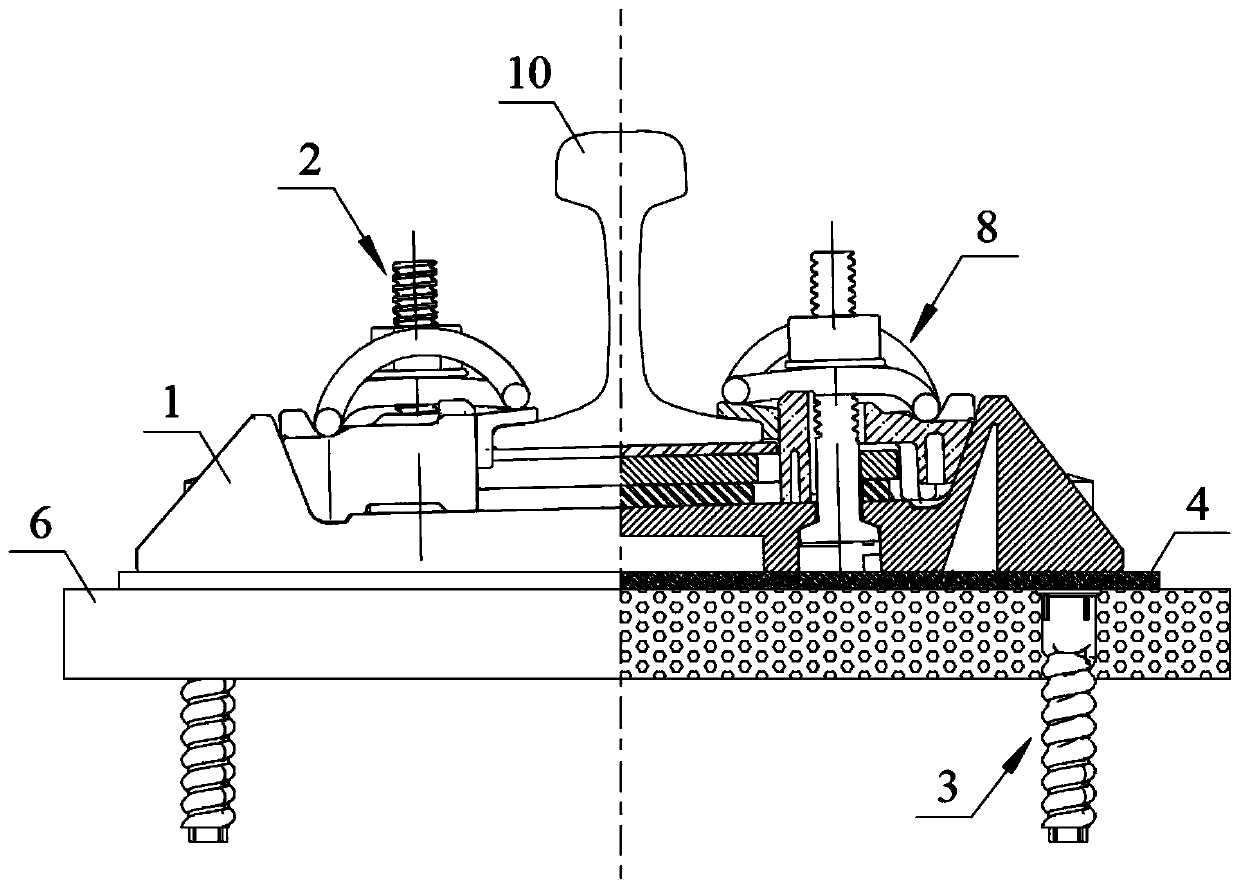

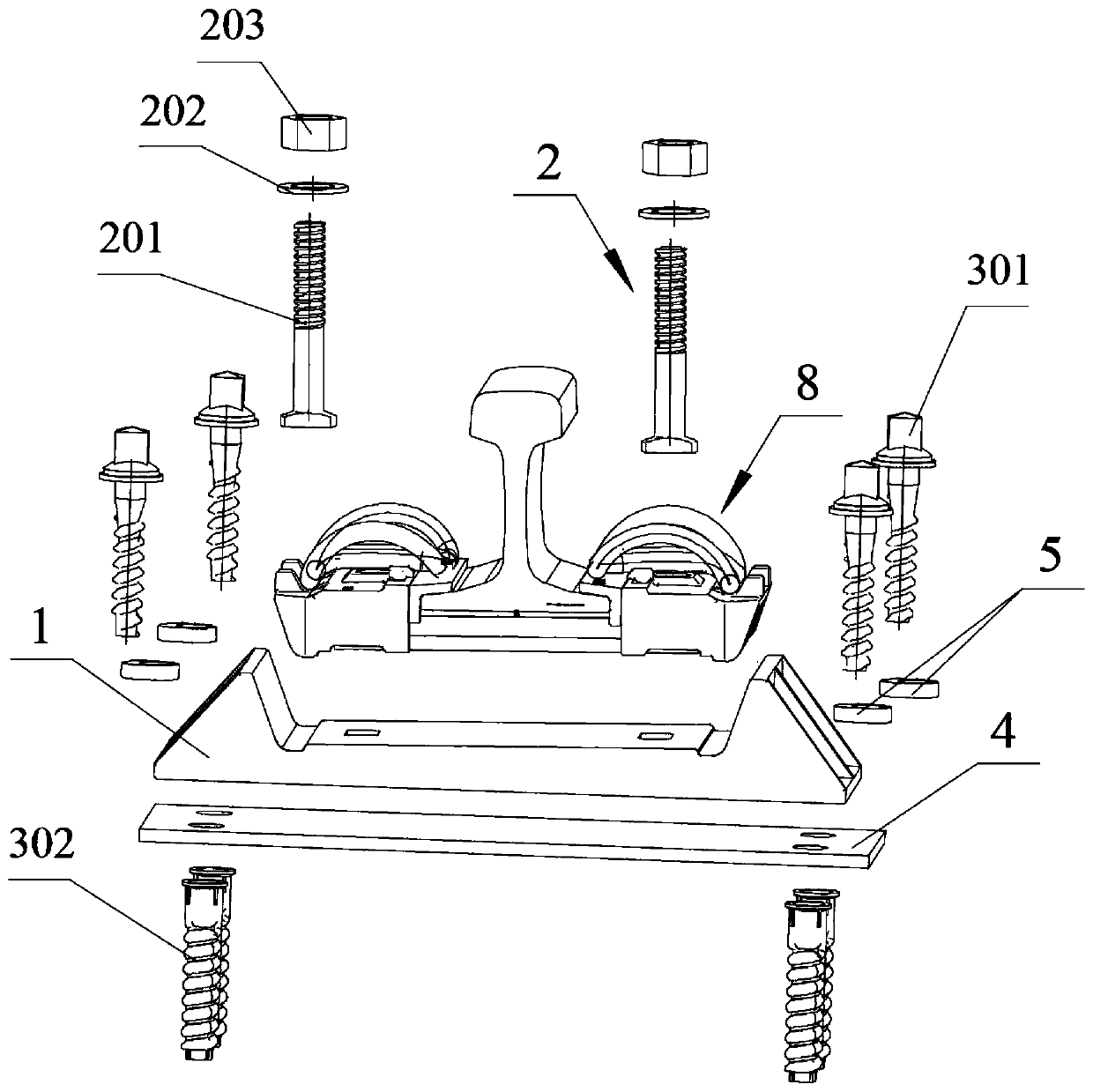

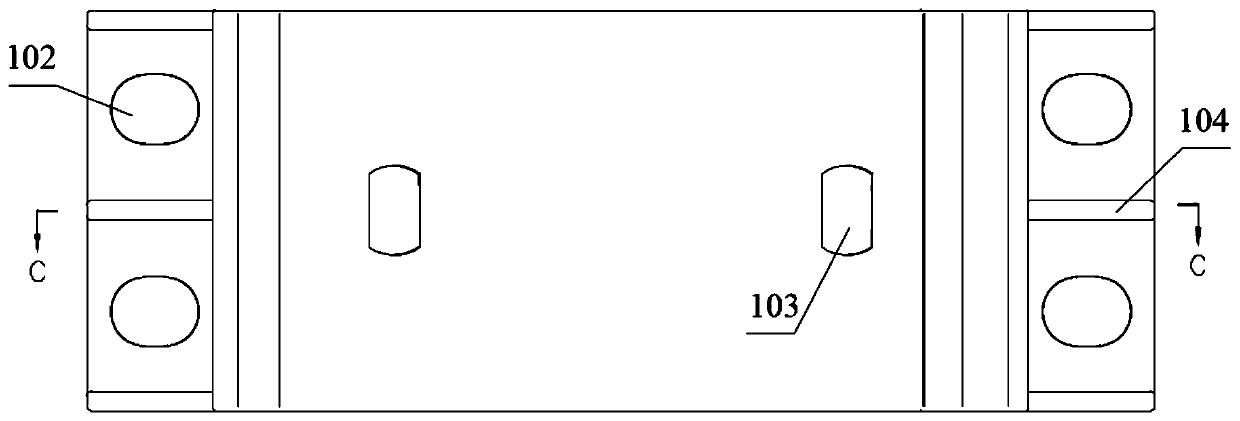

[0052] In the preferred embodiment of the present invention, the settlement adjustment system applicable to the ballastless track with a shoulder is as follows: figure 1 , 2 As shown in , it is mainly used for the vertical height adjustment and horizontal gauge adjustment of the rail 10 in the settlement section of the ballast bed 9 . Specifically, the settlement adjustment system includes a cast-in-place boss 6 arranged in the settlement area of the ballast bed 9 and a base 1 that can be fixedly arranged on the cast-in-place boss 6 , and the rail 10 can be fixed on the base 1 with fasteners 8 correspondingly. And when the base 1 is fixed, the preferred setting of the waist-shaped distance adjusting ring 5 completes the adjustment of the rail 10 gauge.

[0053] More specifically, the settlement adjustment system in the preferred embodiment includes a base 1 , an elastic strip buckle assembly 2 , a ballast bed connection assembly 3 , a waist distance adjusting ring 5 , and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com