Steel-concrete combined wedge-shaped waterstop structure

A water-stop, wedge-shaped technology, applied in infrastructure engineering, construction, etc., can solve the problems of difficult design, repeated switching, narrow space, etc., and achieve the effect of low overall cost, convenient maintenance and use, and guaranteeing water-stop performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing by specific embodiment:

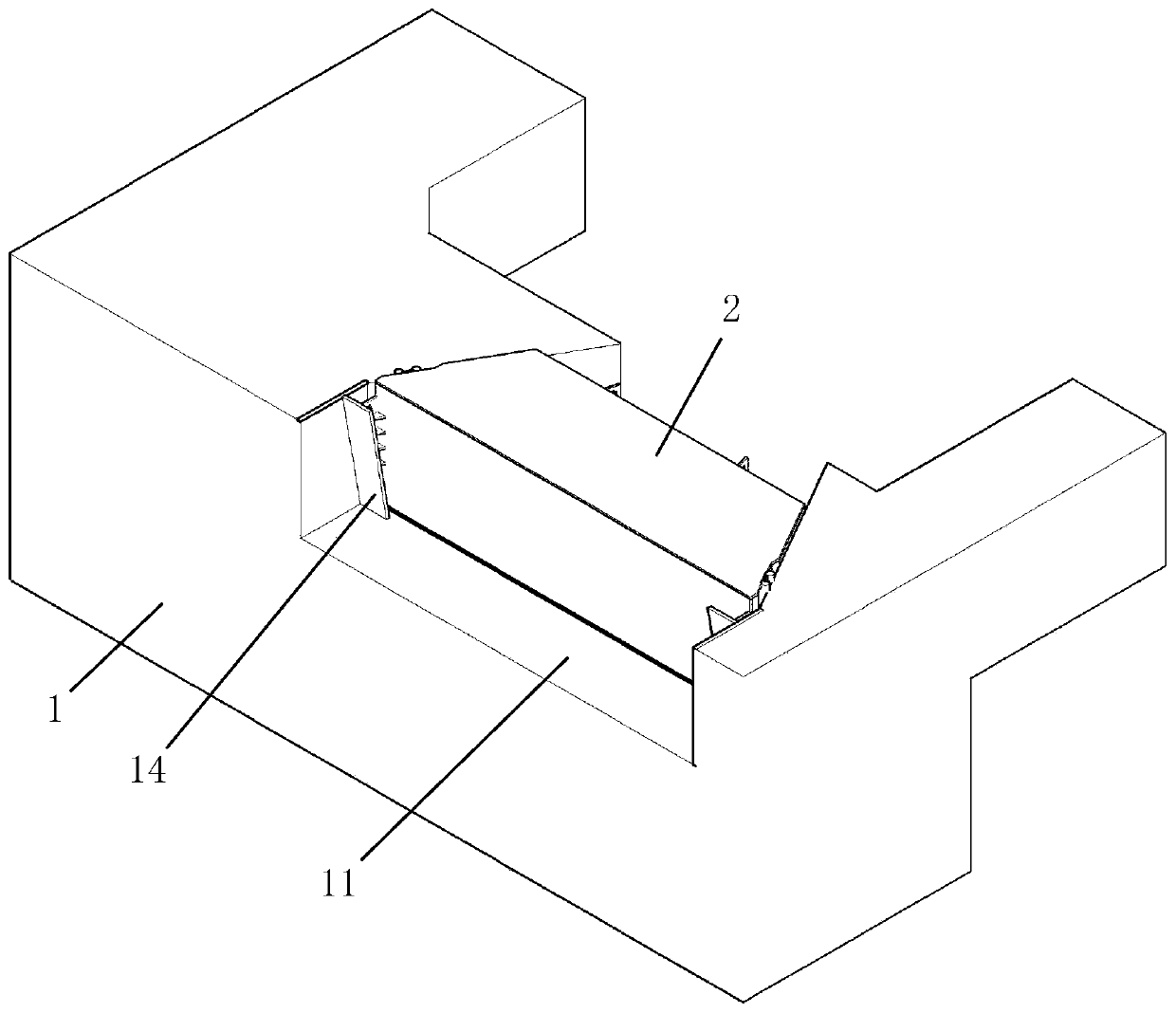

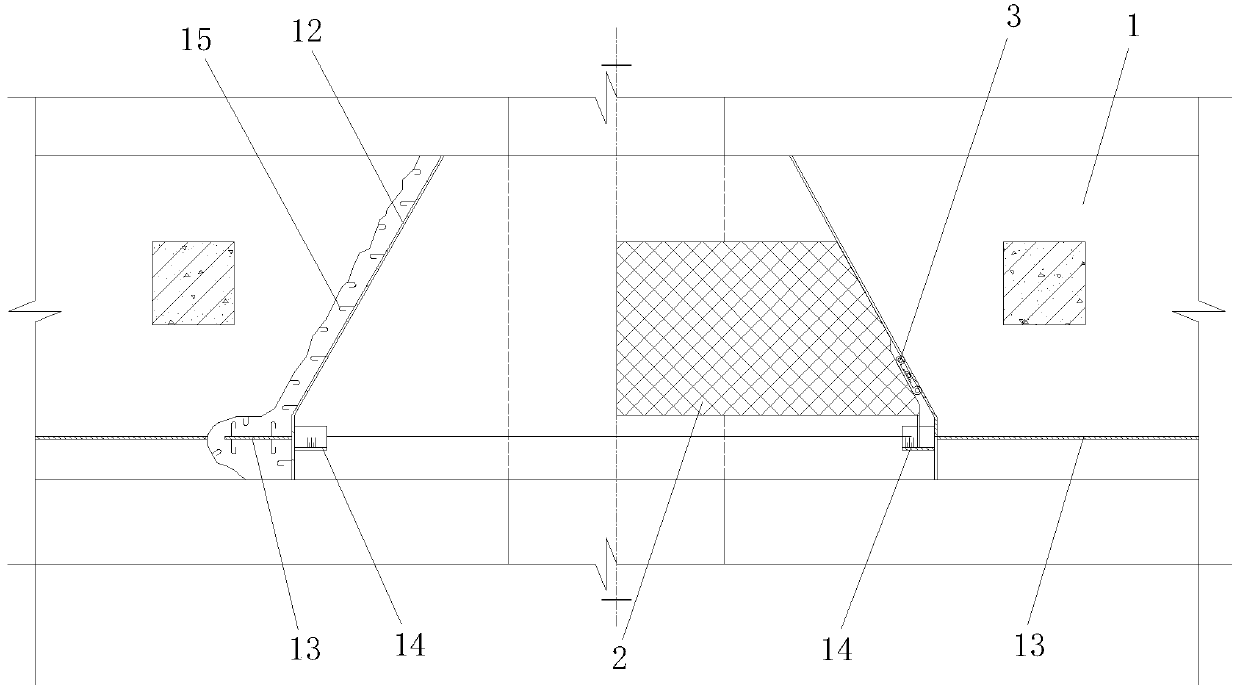

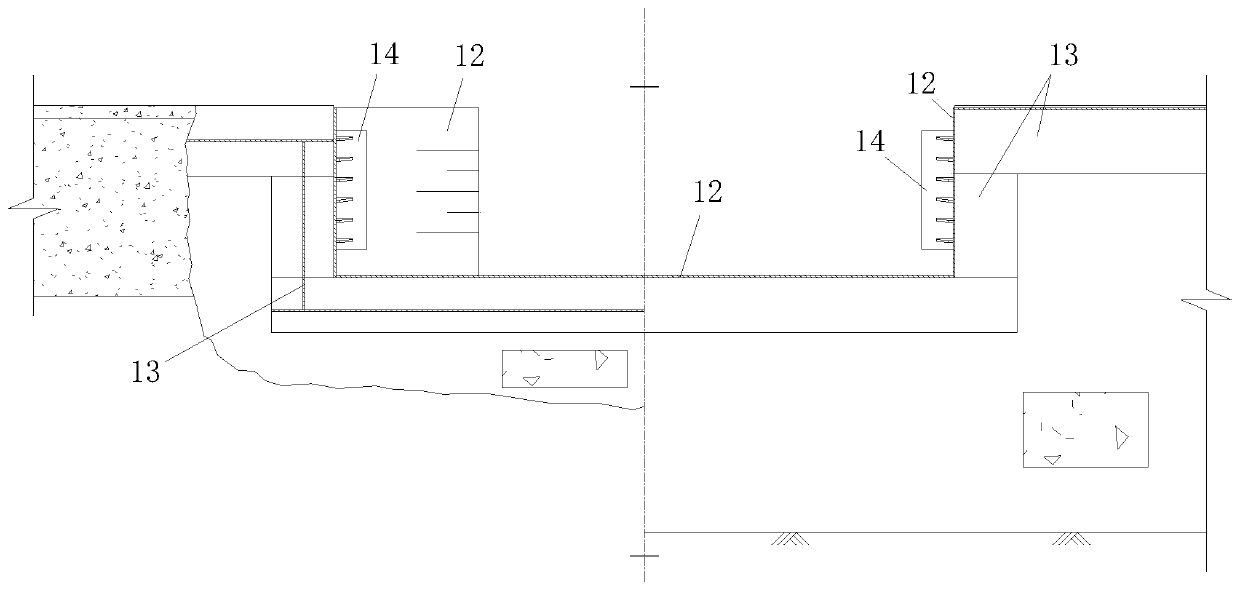

[0023] In this example, refer to Figure 1-Figure 8 , the steel-concrete combination wedge-shaped water-stop structure includes a channel foundation 1 and a water-stop block 2, the channel foundation 1 has a wedge-shaped channel 11, and the width of the wedge-shaped channel 11 is that the waterside (front end) is wider than the backwater side ( The wedge-shaped structure of the width of the rear end); the water stop block 2 is a wedge-shaped structure (similar to a trapezoid) that matches the shape of the wedge-shaped channel 11, and the width of the water-facing side (front end) is greater than the width of the back water side (front end); the water-stop block 2 Rubber waterstops 3 are provided on the bottom surface and both sides in contact with the channel foundation 1. After the waterstop block 2 is embedded in the wedge-shaped channel 11, the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com