Steel column lifting, welding and quick positioning device

A positioning device and hoisting technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inability to ensure the installation accuracy of steel columns, no provision of steel column position adjustment measures, low hoisting operation efficiency, etc., to improve the installation. Efficiency, safe and stable installation, precise positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

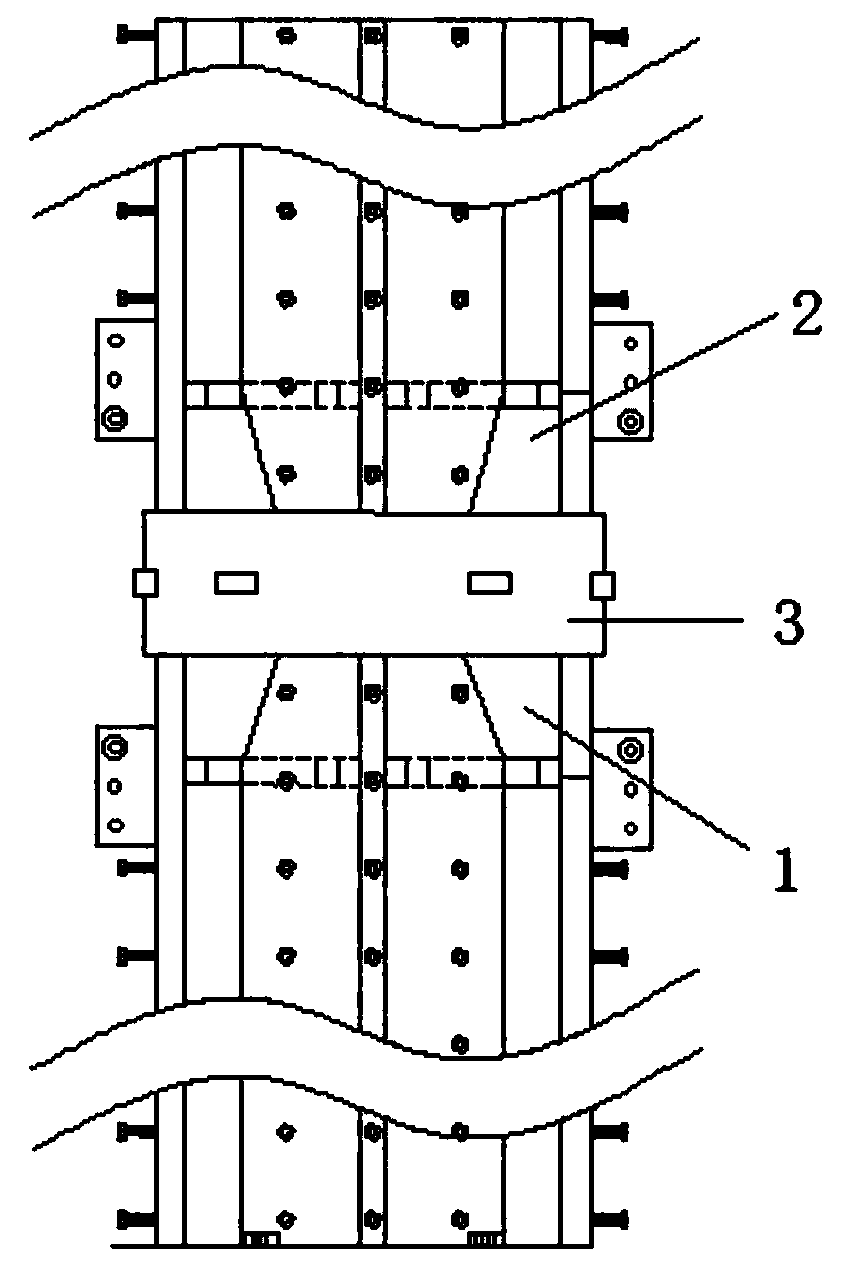

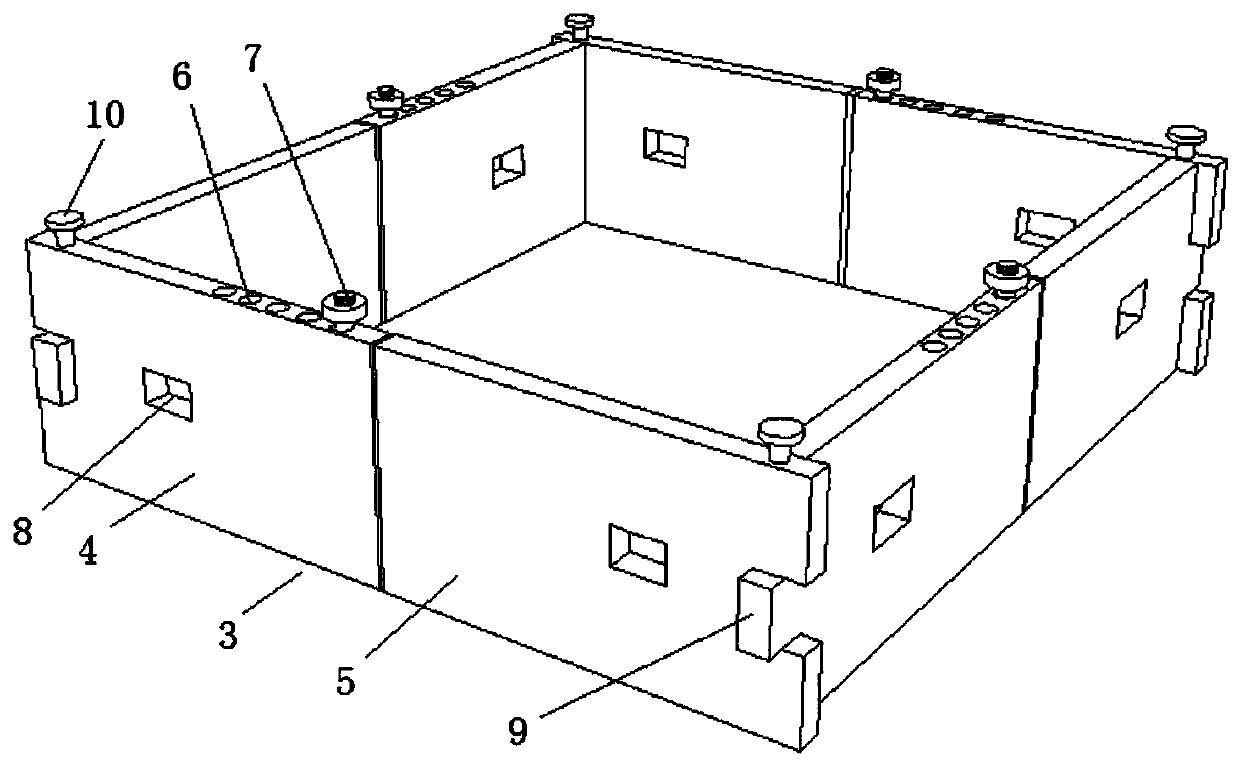

[0012] Such as Figure 1-2 As shown, a steel column hoisting and welding rapid positioning device includes four positioning steel plates 3 that can be spliced with each other to form a rectangle. The positioning steel plates 3 include a main steel plate 4 and an auxiliary steel plate 5 partially slidably inserted into the main steel plate 4 The end of the auxiliary steel plate 5 inserted into the main steel plate 4 is vertically provided with limit pin holes, and the upper and lower sides of the main steel plate 4 are provided with a plurality of bolt holes 6 matching the limit pin holes. A limit bolt 7 is arranged in the limit pin hole and the bolt hole 6 , and the main steel plate 4 and the auxiliary steel plate 5 are provided with welding ports 8 .

[0013] Such as figure 2 As shown, the end of the main steel plate 4 is provided with a protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com